70-Ton Industrial Friction Winch | SEW Motor, PLC Control & High-Precision Traction

Precision Friction Winch Engineered for Heavy-Duty Reciprocating Motion in Energy, Aerospace, Military and Industrial Applications

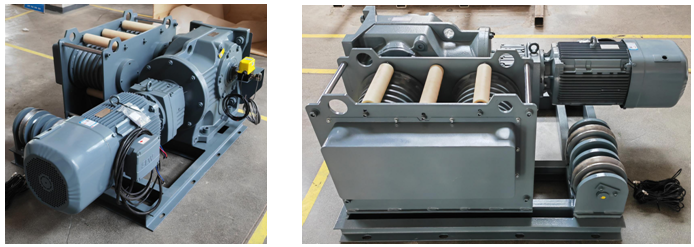

This European-style industrial friction winch is a custom-engineered 70-ton-class traction system designed specifically for energy storage power stations in Turkey. With exceptional stability, precise control and robust structural integrity, it is built for reciprocating motion, long travel distance pulling, high-frequency industrial operations and synchronized multi-equipment systems.

It is ideally suited for rail-car traction inside energy storage stations, heavy equipment relocation, precision manufacturing lines, special research facilities and high-demand environments requiring accurate positioning, long service life and intelligent control.

1. Key Technical Advantages

✔ SEW Geared Motor: High Power, High Stability

Powered by a SEW high-efficiency geared motor, the winch delivers:

- Strong and consistent torque output

- Energy-efficient operation

- Smooth acceleration and deceleration

- High durability under continuous heavy loads

This ensures reliable traction performance for rail cars and other heavy-duty systems.

✔ Integrated Load Cell for Real-Time Tension Monitoring

A built-in force sensor provides continuous monitoring of rope tension, enabling:

- Overload protection

- Predictive maintenance

- Real-time operational diagnostics

- Safer handling under complex working conditions

Operators gain full visibility of system status at all times.

✔ PLC Touch-Screen Control System

The system includes a PLC-based intelligent control panel with:

- Manual / Automatic dual-mode switching

- Parameter adjustment

- Fault alarms and data visualization

- Improved operational safety and repeatability

This makes the winch suitable for engineering environments requiring precise speeds, repeat positioning and automated workflows.

✔ Absolute Encoder for Position, Speed and Travel Tracking

The absolute encoder provides:

- Real-time counting of drum revolutions

- Accurate calculation of car speed, travel distance and movement trajectory

- High precision even in long-distance or repeated cycles

Perfect for testing platforms, R&D labs, and industrial facilities requiring data-driven motion control.

✔ Optimized Steel Wire Rope Guiding Structure

The horizontally arranged guide wheels:

- Reduce rope running height

- Minimize mechanical wear

- Prevent rope deviation during long strokes

- Enhance safety and extend rope lifespan

Especially effective for traction systems operating in tight spaces or complex industrial layouts.

✔ Ground-Mounted Electrical Cabinet

The separate electrical cabinet ensures:

- Improved heat dissipation

- Easy maintenance

- Enhanced system stability

- Safer long-term operation

Suitable for harsh industrial environments where reliability is critical.

2. Technical Specifications (Reference Configuration)

| Item | Specification |

|---|---|

| Model | 7000 kg (70-ton-class traction application) |

| Rated Pulling Capacity | 7000 kg |

| Steel Wire Rope Diameter | 18 mm |

| Motor Power | 7.5 kW |

| Rope Speed | 5 m/min |

| Rope Length | 20 m |

| Drive System | SEW geared motor + friction drum |

| Control System | PLC touch screen + encoder feedback |

All parameters are fully customizable based on project needs.

3. Application Scenarios

Heavy Industrial Transportation

- Rail-car traction inside energy storage stations

- Port heavy equipment shifting

- Oil, gas and power equipment maintenance

- Aerospace and military assembly lines

Built to handle continuous heavy loads with high positional accuracy.

High-Precision Operations

- Specialized testing platforms

- Research institutes requiring controlled reciprocating motion

- High-precision positioning in automated systems

- Environments requiring explosion-proof or high-stability equipment

Challenging Working Conditions

- Multi-equipment synchronized operations

- Long-distance traction with variable loads

- Uneven or complex terrain

- High-frequency movement cycles

4. Why Partner with KLD Winch

KLD (Beijing Tianheng Kairui Lifting Machinery Co., Ltd.) is a professional manufacturer of industrial winches serving military, energy, aerospace, and high-end engineering sectors.

Engineering & Development

- In-house engineering team

- Free 2D/3D drawings and dynamic simulation

- Deep customization for traction speed, rope length, control modes and power systems

- Strong R&D capability for special environments

Manufacturing & Quality Control

- 16+ years of experience in heavy industry

- Precision machining equipment

- ISO 9001 / ISO 14001 compliant

- Military-grade inspection standards

Full Lifecycle Service

- Design → Production → Installation → Training → Remote support

- 48-hour global emergency response

- Dedicated project engineers for technical communication

KLD ensures your project receives not only equipment, but a reliable engineering solution.

5. Request a Technical Proposal

For a detailed configuration plan and quotation, please share:

- Required pulling capacity

- Application scenario (rail-car traction, equipment moving, test platform, etc.)

- Motion mode (reciprocating, long-stroke, precision stop, automation integration)

- Rope diameter & length

- Installation layout or available space

- Voltage & control requirements

- Environmental conditions (temperature, dust, humidity, explosion-proof needs)

We will deliver:

- Engineering selection proposal

- 2D/3D drawings

- Technical parameters

- Delivery schedule

- Competitive quotation