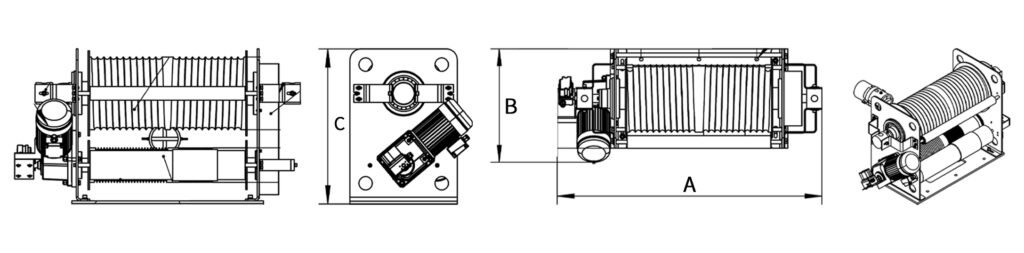

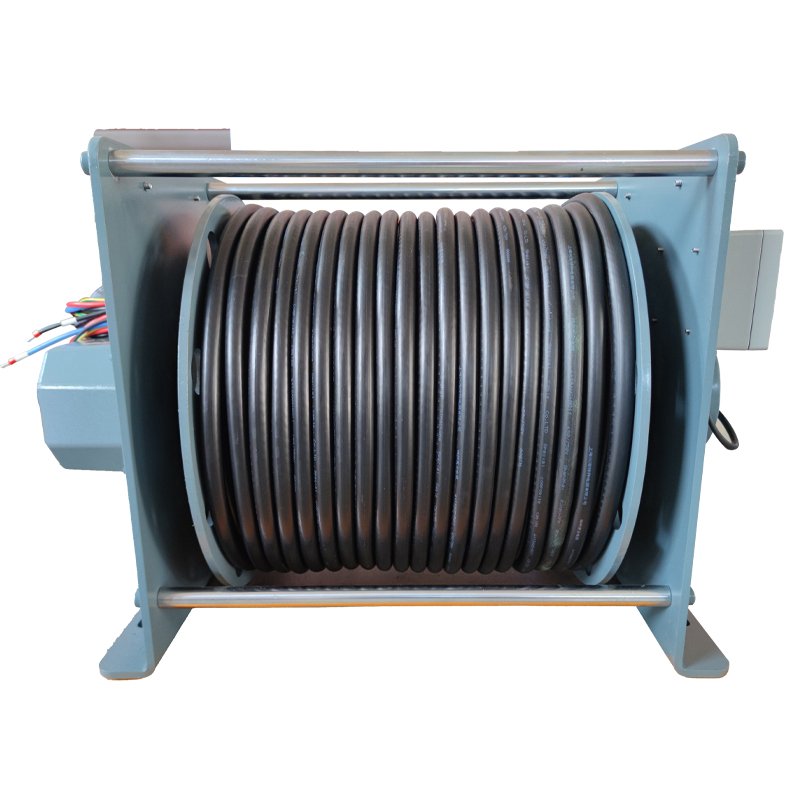

Engineered for the extreme demands of Mining, Port Logistics, and Industrial Automation, this multifunctional reeling machine is the ultimate solution for complex media transmission. It replaces the need for multiple independent reels by integrating Power, Data, and Pneumatics into a single, compact unit.

Capable of handling loads up to 8000kg, this system simultaneously manages two hoses, one power cable, and one wire rope. It features a revolutionary Differential Speed Synchronization design, ensuring that the load-bearing wire rope takes the strain while delicate hoses and cables remain tension-free, significantly extending their operational life.

Linkedin

Linkedin

Google +

Google +