Looking for an industrial winch that matches your load, speed, travel, and control logic—not the other way around? At KLD we engineer electric winches from compact 0.5-ton units to multi-ton project builds, with proven cases in the 20–70-ton class for heavy pulling and test rigs. We’ll size the drum, rope path, enclosure, and PLC/VFD control around your application and return a spec & quote fast.

What You Can Configure (and Why It Matters)

- Rated pull & duty: From light 200–500 kg tasks up to multi-ton continuous pulling; S-duty matched to your duty cycle to protect motors & brakes.

- Line speed: Precision variable speed via VFD/servo; typical ranges 7–20 m/min, with high-speed options up to ~60 m/min when required.

- Travel (rope capacity): From short lifts to 300–500 m long-travel with level-wind/grooved drums to protect rope and layer quality.

- Environment: Standard coated steel or stainless-steel builds for marine/food/chemical, sealed bearings, and IP-rated enclosures.

- Controls & safety: VFD/servo drives, PLC/HMI, encoders for length/speed, e-stops, travel/overload limits; manual or automatic modes.

Model Families & Typical Use Cases

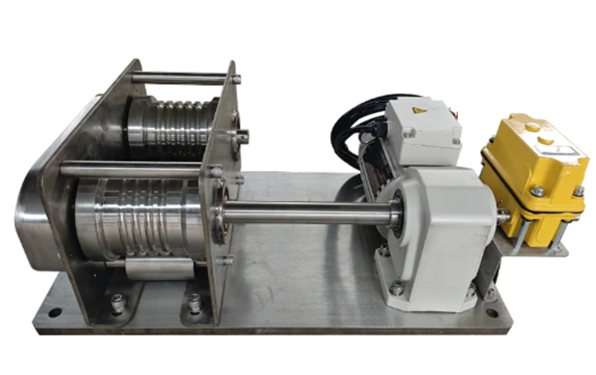

1) Direct-Drive Electric Winches (Compact, Efficient)

- High-efficiency packages with smooth speed curves and low maintenance.

- Ideal for factory pulling and durability test benches where footprint and efficiency matter.

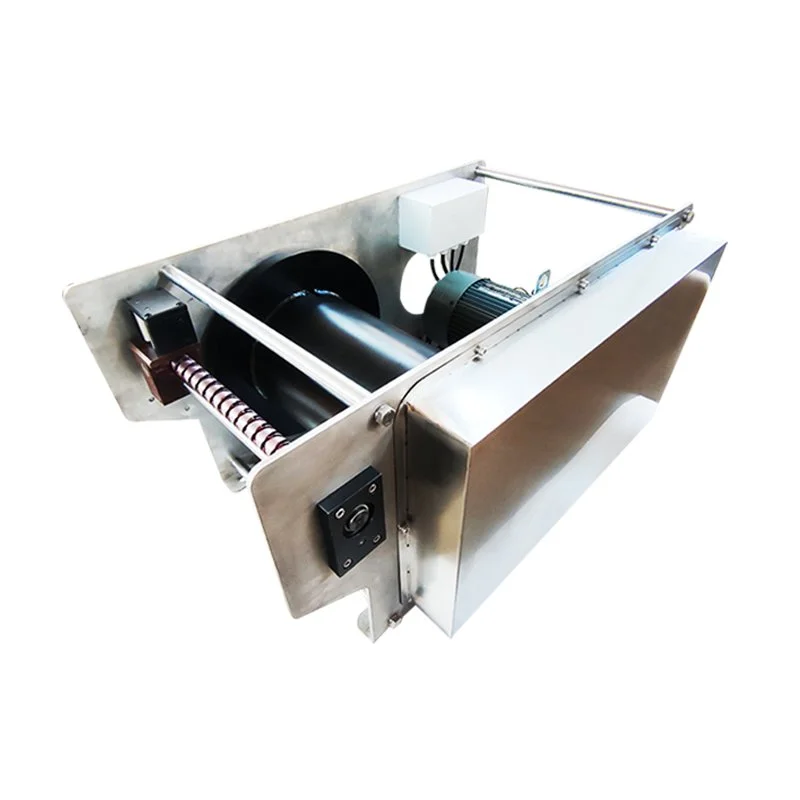

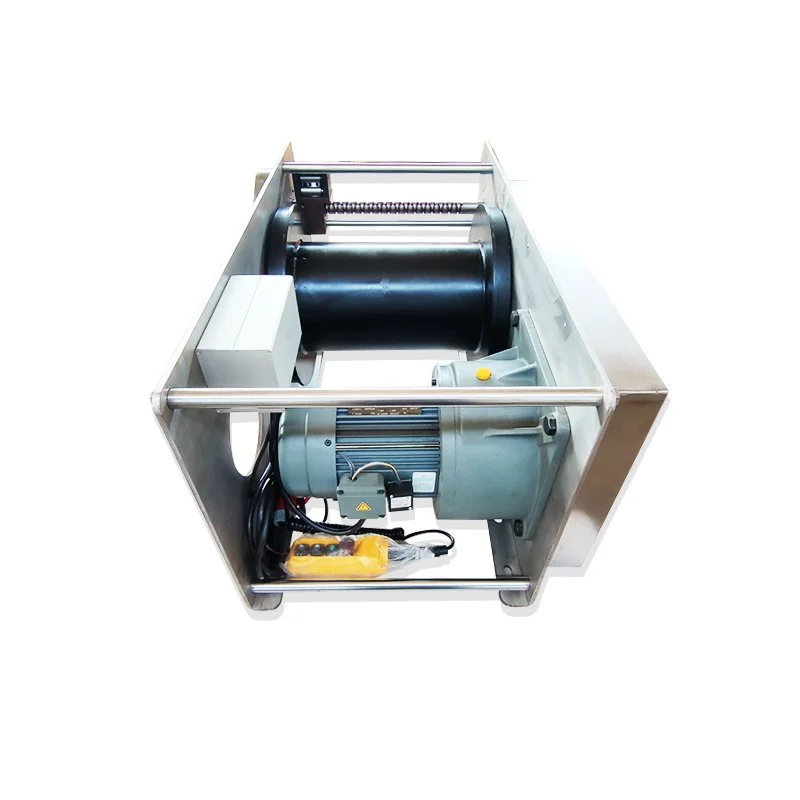

2) Friction Winches (Constant-Speed Long Travel)

- Designed for steady traction with rope storage behind the friction drums—perfect for bridge/pipeline pulls and railcar movement.

- Example scope: up to ~70-ton custom traction projects.

3) Stainless-Steel Winches (Corrosion-Resistant)

- SS304/316 construction, anti-corrosion design for marine/outdoor/clean-room use.

- Spec coverage from 500 kg to 1 ton and beyond; stainless friction variants available for reciprocating traction.

4) High-Speed & Servo/Encoder Winches (Precision Control)

- Servo or VFD packages; line speed up to ~60 m/min; encoder-based metering for rope length & velocity—great for labs and synchronization tasks.

5) Long-Travel / Parallel & Split-Reel Systems

- Engineered for 300–500 m lifting height or long horizontal pulls; optional level-wind, split reels, multi-rope synchronization for large fixtures (chandeliers, test trays, etc.).

6) Special-Purpose & Test-Rig Winches

- Units with height & force sensors for test labs; constant-speed solutions for EV durability lines; PLC safety interlocks for heavy test trays (~20-ton class).

Typical Spec Snapshots (Indicative)

- Heavy-duty electric winch: 5-ton rated pull, ~22 kW motor, rope length around 300 m, rope Ø20 mm.

- Friction winch: average rope speed ~10 m/min, 3-phase 380–480 V; models commonly up to 7-ton traction, scalable.

- Compact units: ~320 kg rated tension, ~7.5 m/min; ideal for light fixtures and positioning.

- Auto rope-feeding traction: ~250 kg pull, ~300 m rope, ~15 m/min average speed.

Need 0.5–50+ ton? We’ll map your load case to a proven platform (friction/drum/servo) and scale components accordingly; our case history covers 20–70-ton projects.

Pricing & Lead Time — What Drives Your Cost

Your price is determined by rated pull, line speed & duty, travel/rope management, materials (stainless vs coated steel), and control stack (VFD/servo/PLC/HMI/safety). High-speed constant-speed packages and stainless builds price higher; long-travel adds to drum and rope-guide complexity. Share your requirements and drawings; we’ll return a clear spec sheet + itemized quote.

Selection Checklist (Copy/Paste into Your RFQ)

- Rated pull (kN/ton) and duty (S-class)

- Target speed (m/min) & tolerance

- Travel (m) and rope type/Ø; need level-wind/grooved drum?

- Power (380/400/415/440/480 V; 50/60 Hz)

- Control: VFD/servo, PLC/HMI, remote, safety interlocks, encoders (length/speed)

- Environment: indoor/outdoor, temperature, stainless or coated, IP rating

- Mounting & space constraints; accessories (sheaves, anchors)

- Documentation & test: FAT, load test, certificates; packaging and delivery window

Frequently Asked (Fast Answers)

Q1. Can you synchronize multiple winches for even load and position?

Yes—via PLC master/slave logic with encoder feedback and limit/safety interlocks. This is common on lab trays and split-reel/chandelier systems.

Q2. How do you guarantee constant speed under varying loads?

By pairing a VFD or servo drive with closed-loop feedback (encoder), plus tuned control curves. Friction winches and servo drums are typical for constant-speed requirements.

Q3. What’s your longest standard travel?

Standard solutions around 300 m are common, with engineered systems up to ~500 m on long-lift or long-pull projects.

Q4. Do you build stainless-steel versions for marine/clean environments?

Yes—electric and friction types with corrosion-resistant structures and sealed components.

Q5. How fast can you go?

Application-dependent. High-speed traction examples reach around 60 m/min with encoder-based metering for protection and accuracy.

Call to Action — Get a Tailored Spec & Price

Send us your load, speed, travel, rope, power, and control preferences. Our engineers will respond with a bespoke spec sheet, layout recommendations (drum, rope guide, level-wind), and a firm quote with lead time that matches your project schedule.