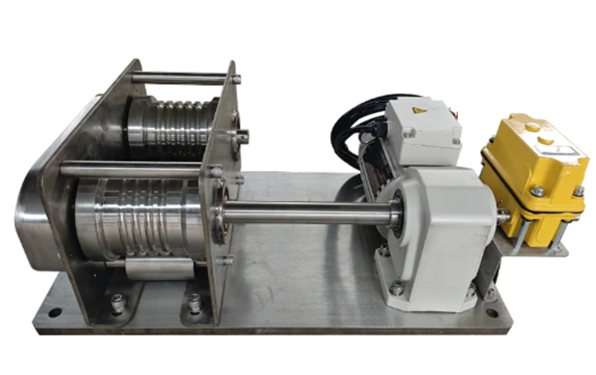

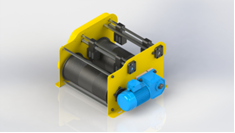

Aluminium Alloy Rope-Out Winch | Lightweight, Corrosion-Resistant | OEM/ODM Factory

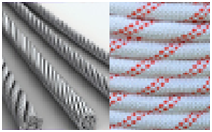

The Aluminium Alloy Rope-Out Winch is a compact, light-duty industrial winch designed for clean, controlled rope pay-out in tight spaces. Its aluminium-alloy construction keeps weight low while improving corrosion resistance for outdoor and coastal use. Ideal for fixtures, test benches, small equipment handling, and instrument deployment, it’s a plug-and-play unit you can mount quickly and operate safely.

Key Highlights

- Aluminium-alloy build — Lightweight and corrosion-resistant for easier handling and longer service life.

- Stable rope pay-out — Optimised outlet structure for neat, smooth rope feed; reduces tangling and protects the wire rope.

- Compact footprint — Small geared-motor package fits into cabinets, racks, and mobile rigs.

- Easy operation — Forward/Reverse, emergency stop, and limit protection; pendant control standard, panel/wireless optional.

- OEM/ODM ready — Rope diameter/length, drum groove, outlet guide, brackets, and control options can be tailored to your site.

Core Specifications (from the product page)

- Rated pulling force: 200 kg

- Motor power: 0.75 kW

- Rope pay-out speed: ≈11.69 m/min

- Wire rope diameter: 4 mm

- Drum rope capacity: 20 m

(If you need more capacity or a different rope, we’ll size the drum and guide accordingly.)

Typical Applications

- Bench/test rigs: precise rope delivery for calibration or durability runs

- Small equipment loading/positioning: controlled pulling in maintenance bays

- Instrument deployment & retrieval: neat pay-out for sensors, probes, or tethers

- Light hoisting assist: guided take-up where compact size is essential

Configuration Options

- Rope & drum: 3–5 mm rope range, custom groove pattern, longer storage (multi-layer) if required

- Guidance: outlet guide/pressing device, fairleads, sheaves, level-wind (for longer travel)

- Controls: pendant + panel; optional wireless set; speed display; counter/encoder for length read-out

- Enclosure & protection: splash-resistant cabinet, enhanced coatings, stainless fittings for harsh sites

- Mounting: base frame, vertical/horizontal brackets, vibration pads, lifting points

- Documentation & tests: FAT, wiring diagrams, datasheet pack, crate for sea/air shipment

What Affects Price & Lead Time

- Load & duty (intermittent vs frequent cycles)

- Rope package (diameter, total length, groove pattern, guiding hardware)

- Control stack (basic pendant vs panel + wireless; length/speed display; PLC/encoder)

- Materials & protection (standard aluminium alloy vs stainless hardware, cabinet IP class)

- Compliance & docs (FAT, certificates, custom manuals)

RFQ Checklist (copy, fill, and send)

- Rated pull (kg) and duty (cycles/hour):

- Target rope speed (m/min) and tolerance:

- Rope diameter & total length (mm / m):

- Pay-out path & guidance needs (level-wind, outlet guide, sheaves):

- Power on site (voltage/frequency):

- Control preference (pendant / panel / wireless; need length/speed display?):

- Environment (indoor/outdoor, temperature, corrosion considerations):

- Mounting space & orientation (base/bracket details):

- Documents/tests required (FAT, certificates) and target ship date:

We’ll reply with a tailored specification, itemised quote, and production schedule—plus layout suggestions for rope guidance and mounting so you can install once and run reliably.