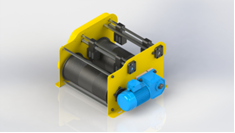

Stainless Steel Friction Winch | 316 SS | Constant-Speed Traction | PLC/Encoder | OEM/ODM

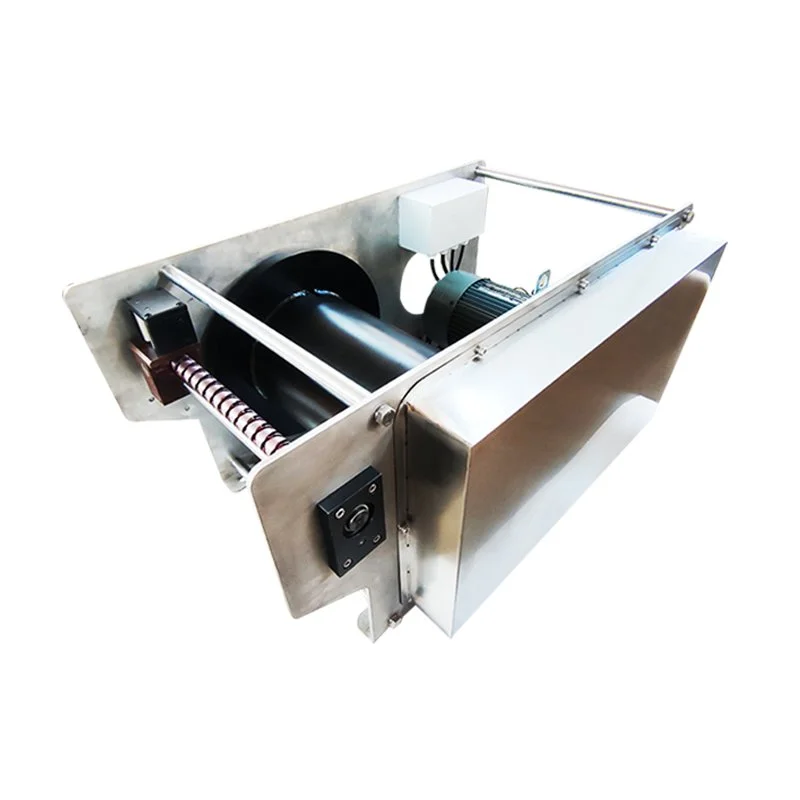

Built for harsh and hygiene-critical environments, the Stainless Steel Friction Winch combines a 316 stainless-steel structure with constant-speed traction and PLC/encoder control. It excels on marine/coastal sites, food/chemical facilities, and outdoor long-travel pulls where corrosion resistance, smooth speed, and easy operation matter most.

Why Choose This Winch

- 316 stainless-steel build — Excellent resistance to salt spray, humidity, and wash-down routines.

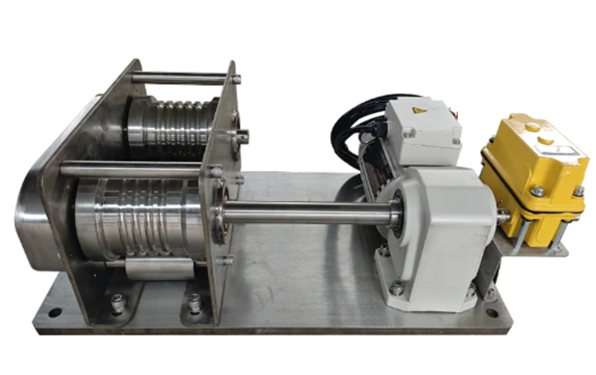

- Constant-speed traction — Friction drums keep line speed steady and decouple spooling quality from storage layers; ideal for long travel and reciprocating pulls.

- OEM/ODM flexibility — Drum/rope path, storage, cabinet layout, I/O, mounting frames, and documentation tailored to your standards.

Typical Configurations (Indicative — Customized per Order)

| Version | Traction Force | Nominal Line Speed* | Rope Path | Structure | Control & Safety |

| SS-Friction-1T | ~1 ton class | 8–20 m/min | Friction drums + compact storage | 316 SS frame/panels | PLC touchscreen, encoder, E-stop, limits |

| SS-Friction-3T | ~3 ton class | 6–15 m/min | Friction drums + level-wind storage | 316 SS + sealed bearings | PLC, encoder, alarm/event logs |

| SS-Friction-HS | Application-specific | up to ~60 m/min | High-speed traction | 316 SS | PLC/encoder, sequencing & interlocks |

*Speed ranges are tuned to your duty cycle and safety margins during engineering review.

Customizable elements: traction force, drum diameter/width/groove, level-wind type, rope diameter/type, cabinet IP rating, PLC/HMI brand, field wiring, labels/docs, and surface finish.

Where It Excels

- Marine / coastal: piers, deck equipment, small-craft handling, and seaside infrastructure.

- Food / chemical: hygiene-sensitive areas needing stainless materials and cleanable surfaces.

- Long-travel positioning: labs and sites that require constant speed with accurate length metering.

Control & Safety Package

- PLC + touchscreen HMI with auto/manual, presets, alarms, and diagnostics

- Encoder feedback for length/speed display and data logging

- Limit switches (upper/lower), E-stop chain, overload/torque protections

- Braking: electromagnetic or fail-safe options, monitored in the control logic

- Integration: I/O for line PLC/SCADA, beacon/buzzer, interlocks, remote enable

Options: stainless or coated electrical cabinet, level-wind/storage drum, remote pendant/wireless set, heaters for low-temperature sites, brand-specified drives/PLC/HMI.

FAQ

Q1: Why choose a friction winch instead of a drum storage winch?

Friction traction keeps line speed constant and isolates storage from working traction, improving speed stability and reducing layering issues on long travel.

Q2: Can the system log actual speed and length for QA?

Yes. Encoder values are displayed on the HMI and can be mapped to SCADA for data logging.

Q3: Do you offer stainless cabinets and accessories too?

Yes. Control cabinets, fasteners, guards, and exposed hardware can be supplied in stainless with appropriate IP protection.

Q4: What if I need both long travel and perfect layering?

Specify rope Ø and total travel; we’ll size the storage drum and provide level-wind solutions to protect rope life.