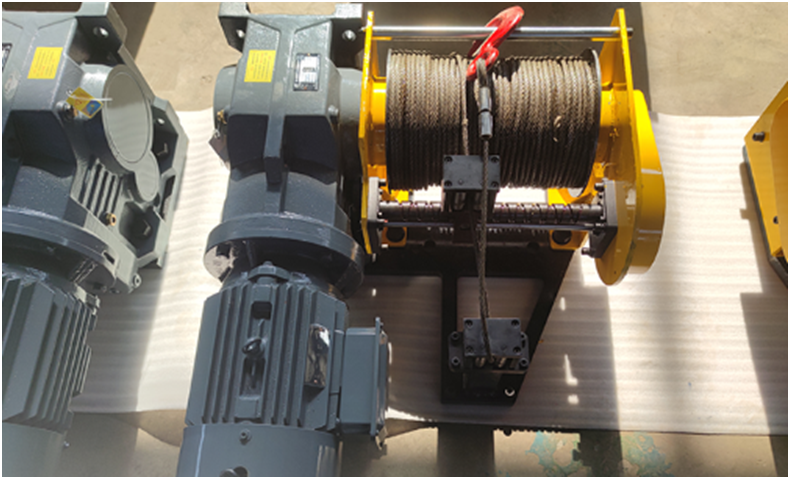

Equipment-Integrated Winch | 0.5–50+ Ton Custom Load | PLC / VFD Synchronized Pulling & Hoisting Solutions

In automated production lines, equipment integration and tooling upgrades, pulling and lifting often look like “just supporting motions”, but they usually determine how stable the whole machine runs: whether the speed is smooth, positioning is accurate, synchronization is reliable, and long-term operation is trouble-free.

KLD equipment-integrated winches are designed for machine builders, line integrators and retrofit engineers. The goal is simple: make the winch behave like a native part of your equipment, both mechanically and in the control logic, so that you deliver more stable machines and spend less time on after-sales.

What a “truly integrated” winch must get right

From KLD’s electric industrial winch models and project cases, the key parameters for integration fall into four main dimensions:

1) Load range – from light modules to heavy systems

The KLD electric industrial winch portfolio covers customized loads from 0.5 tons up to 50+ tons, with engineering cases in the 20–70 ton range for heavy pulling and test rigs.

That means we can cover scenarios from small trolley pulling and tooling lifts on the line, all the way to dragging large equipment or shifting heavy molds, always based on real working conditions instead of a one-size-fits-all model.

2) Speed & cycle control – VFD / servo makes motion “controllable and calculable”

An integrated winch must follow your takt time; it shouldn’t rely on operators “nudging” it into place.

KLD’s equipment / servo-type winches publish typical controllable speed configurations, for example:

- 500 kg servo twin-drum model

– Rope speed: about 11 m/min

– Motor: 1.1 kW

– Control: PLC

– Used for high-frequency, precise reciprocating motion and positioning - 2000 kg servo twin-drum model

– Rope speed: about 10 m/min

– Drum capacity: about 31 m rope

– Used where higher loads still require stable pay-in/pay-out

These examples show that an equipment-integrated winch can be configured with a speed curve that matches your cycle (slow for fine positioning, medium speed for stable pulling, segmented speeds, etc.), and then realized via VFD/PLC/servo with soft start, smooth braking and position-linked control.

3) Wire rope diameter & length – defined by your stroke and reeving

Different equipment has very different stroke lengths, reeving ratios and pulley arrangements, so rope diameter and drum capacity have to follow your design, not the other way round.

Typical configurations in KLD’s integrated/servo series include:

- 300 kg servo model

– 6 mm wire rope for short-stroke, high-precision movements - 500 kg twin-drum model

– 6 mm wire rope, typical rope length 11 m - Light-duty pulling modules

– 3-phase 380 V induction motor + electromagnetic brake

– Focus on stable pulling and customizable mounting options

The practical approach for an integrated winch is:

first calculate reeving and required drum capacity, then select rope diameter and spooling method. This reduces cross-winding, loose layers and later maintenance issues.

4) Installation & linkage – make it part of the machine, not just “a box on the side”

An equipment-integrated winch is not a stand-alone tool; it is an executing unit of the whole machine.

Load, speed, drum geometry, rope exit direction, limits/encoders and I/O communication are all matched to your main machine structure to avoid situations such as:

- The winch takes up awkward space or the rope path is not smooth

- PLC linkage doesn’t align and commissioning takes too long

- Multi-point pulling falls out of sync and the system runs out of track

Typical applications for equipment-integrated winches

Whenever your equipment needs stable “pull / lift / release / rewind” actions, an integrated winch can be built into the system:

- Automated line pulling / return

– Pallets, racks, fixtures, slides and trolleys

- Equipment lifting & positioning

– Lift platforms, AS/RS lifts, tooling height adjustment

- Heavy-duty dragging and shifting

– Equipment dragging, mold shifting, rail transfer

- Continuous pay-in/pay-out / winding systems

– Constant-speed or variable-speed winding, tension control, segmented cycles

- Multi-point / multi-rope synchronous mechanisms

– Symmetrical lifting, twin-point pulling, multiple stations linked together

Six data points that make sizing faster and more accurate

To make the winch behave like a “native part” of your equipment, you only need to provide:

- Maximum load (including reeving / pulley ratio)

- Stroke and required rope capacity

- Speed range and cycle curve

– Do you need segmented speed or constant tension? - Start/stop frequency and duty class

- Site environment

– Dust, humidity, corrosion, temperature - Control method and linkage requirements

– VFD / PLC / servo, limit switches, encoders, communication needs

Based on this, we select the most suitable structure and control configuration from our 0.5–50+ ton product range and engineering experience, and add sufficient safety and service-life margins.

Help your equipment deliver better, commission faster and need less after-sales

The value of an equipment-integrated winch is not “one more winch on the BOM”, but this:

- The pulling / lifting motions follow your machine cycle

- The system runs reliably for years

- Integration and linkage are straightforward for your controls team

If you are working on a new machine, a line integration project or a brownfield upgrade, you’re welcome to send us your working conditions and parameters.

Let’s make the “last mile” of pulling and lifting on your line more stable and more engineered, so your equipment is easier to deliver, easier to commission and easier to maintain.