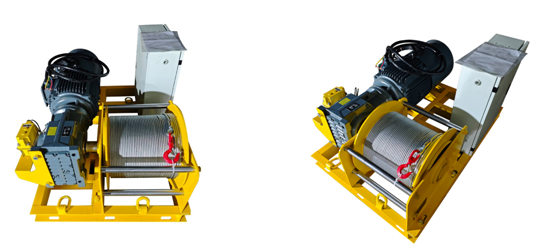

High-Speed Traction Winch | 500 kg Light-Duty High-Speed Traction Solution with VFD Control

The more projects I work on, the more interesting patterns I notice.

In many systems, the required pulling force is not very high, but speed and cycle time matter far more, for example:

- Hundreds or even thousands of back-and-forth cycles per day

- Each stroke is not extremely short, while idle return strokes take most of the time

- The equipment itself is valuable — users fear “slow” more than they fear whether a few hundred kilograms of pulling force is enough

In such scenarios, if you still follow the traditional logic of “bigger tonnage = better”, you will quickly run into problems:

- Tonnage increases

- But the speed cannot keep up

- Operators and clients feel the system is “holding them back”

This high-speed traction winch is designed exactly for these “light load but extremely speed-sensitive” applications:

- 18.5 kW VFD motor

- Rated traction: 500 kg

- Top rope speed: 120 m/min

- Built-in VFD, stepless speed control via a simple knob

- Smooth control in both rope-in and rope-out motions

Below I will share, based on my real project experience:

- What types of applications truly benefit from this winch

- And how you should provide parameters for proper selection

I. Applications Where a High-Speed Traction Winch Truly Excels

1) High-frequency reciprocating traction: Speed = Productivity

Certain use cases are so typical that I can determine whether this winch fits as soon as I hear them:

- Rail-mounted tooling carts or testing trolleys moving back and forth

- Test lines, aging lines, or laboratory rigs requiring frequent reciprocating motion

- Auxiliary traction mechanisms beside production lines where each cycle must sync with the main machine

Common characteristics:

- Loads are light — a few hundred kilograms at most

- Frequent reciprocation — hundreds or thousands of cycles daily

- The biggest complaint is always “too slow”, not “not strong enough”

So for these cases, our design philosophy is:

- Fix the rated traction at 500 kg

- Allocate the motor power & structural optimization to higher speed

- Let the whole system run more “freely and efficiently”

2) Long-travel light-load traction: Idle travel time must be minimized

Another category involves long travel distance but still low load:

- Small testing carts moving along long corridors

- Long-distance hose/cable wire deployment & retrieval

- Moving a device from point A to a far point B, but with minimal load

With a normal-speed winch, the biggest challenge is idle travel consumes most of the cycle:

- First, you must send the rope hook all the way to the working point

- After operation, the rope must be retracted fully to prepare for the next cycle

The “loaded working time” may be only a small portion of the entire cycle.

High-speed traction winches are designed to dramatically shorten this non-productive time while maintaining safe control.

3) Laboratory / testing / experimental rigs: Speed curve controllability is essential

Typical examples:

- Fatigue tensile testing rigs for materials or components

- Long-stroke displacement loading platforms

- Test systems that require specific acceleration/deceleration curves

In such scenarios:

- Load is small

- But requirements for speed stability, repeatability, and adjustability are very high

Our built-in VFD allows:

- Stepless speed control using a knob

- Operation from high-speed near 120 m/min

- Down to low-speed modes for fine adjustments

Very friendly for testing, calibration, and experimental environments.

II. Why intentionally design “High-Power, Light-Load, High-Speed” configuration?

The most common question people ask is:

“18.5 kW motor for just 500 kg traction? Isn’t that overkill?”

Yes — but intentionally.

My reasoning:

1. Light load + high motor power = greater safety margin & speed potential

- Higher motor speed + higher drum surface speed

- Extra buffer for handling sudden resistance or transient acceleration needs

2. Setting the load class at 500 kg allows optimization for “speed-focused” structures

- Drum diameter, rope diameter, guide system, cooling, and structural stiffness

- All can be designed around high-speed operation

- No need for “heavy industrial” structures sized for several tons

3. VFD makes high power controllable, not risky

- Soft start and soft braking

- Smooth rope-in and rope-out

- Operator controls speed easily through the knob

In essence, this winch is more like a high-performance motion actuator rather than a traditional “tonnage-based” winch.

III. If you want me to select this winch for your project, here’s what I will ask

To simplify selection and quotation, I usually ask the following questions.

You can also copy this list directly to send your working conditions:

- What are you pulling/driving?

Trolley? Test bench? Hose? Cable? Custom mechanism? - Maximum pulling load?

Actual mass + friction (rolling/sliding) + slope (if any) - Desired maximum speed?

Any strict cycle requirement? (e.g., “complete X meters within Y seconds”) - Travel distance per cycle?

Stroke per trip & number of cycles per day - Speed control requirements?

Just “faster”? Or specific speed range / multi-segment velocity profile? - Planned control method?

Button box / speed knob / integration with PLC - Installation space & rope direction

Winch mounting location, rope exit direction, need for sheaves or guide pulleys

With this information, I can determine:

- Whether this high-speed traction winch suits your application

- Whether traction force, rope diameter, or rope length needs adjustment

- Whether to use our integrated VFD control box or interface with your PLC

IV. What parameters can be customized for your project?

The configuration 500 kg / 18.5 kW / 120 m/min / 8 mm rope is an example.

We can adjust:

- Load class (within a defined range)

- Speed range (according to your cycle requirements)

- Rope length (drum size / rope diameter adjustable)

- Rope exit direction:

front / rear / upward / with guide pulley

- Control options:

integrated VFD box or PLC terminals

- Material & protection:

outdoor, corrosion-resistant, dust-proof, etc.

This winch is not a “fixed-parameter standard product”

but a customizable platform for speed-critical applications.

V. Working Condition Inquiry Template (Ready to Copy)

Feel free to use this as an email template (also suitable for English inquiries):

High-Speed Traction Winch Selection Request

- Traction object: (rail trolley / test bench / hose / cable / etc.)

- Max pulling load: ____ kg (rolling or sliding? any slope?)

- Travel per stroke: ____ m; cycles per day: ____

- Desired max rope speed: ____ m/min; speed control requirement: ______

- Installation space: L ____ mm × W ____ mm × H ____ mm

- Power / control method: need VFD control box or integrate into my PLC

- Environmental requirements: outdoor / anti-corrosion / dust-proof / explosion-proof

With this information, I can provide a tailored preliminary solution during the first communication.

Final Note

This high-speed traction winch is not meant to compete in tonnage with multi-ton winches.

Its real purpose is to solve the problem:

“When your load is not heavy, but speed, cycle time, and controllability are extremely important — how to achieve a fast, stable, controllable traction system.”

If you have such a project, feel free to share the working conditions.

We can evaluate together:

- Whether this winch fits your scenario

- And how to configure it to run fast and stable