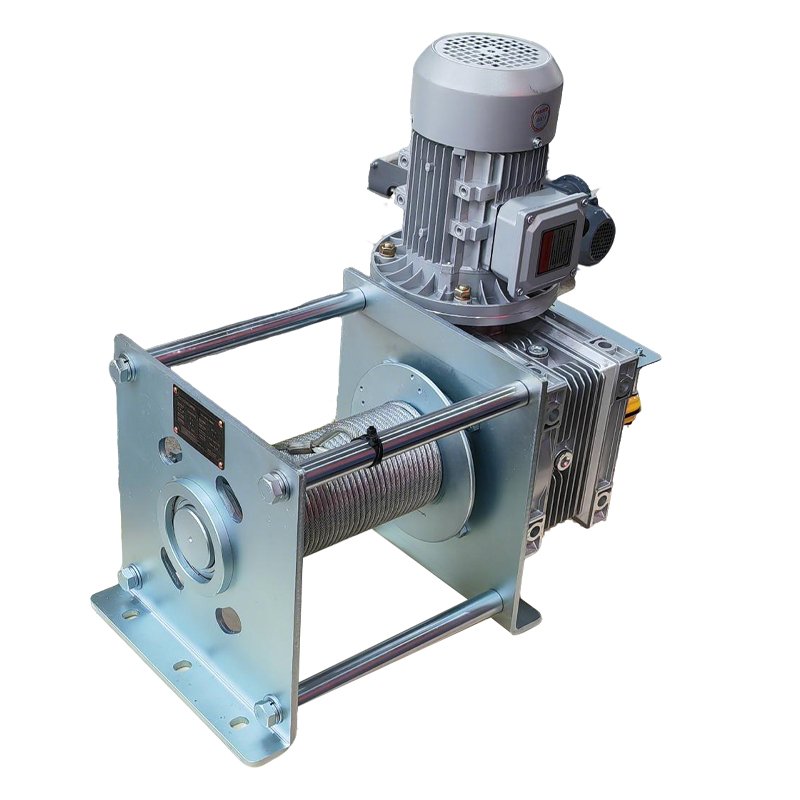

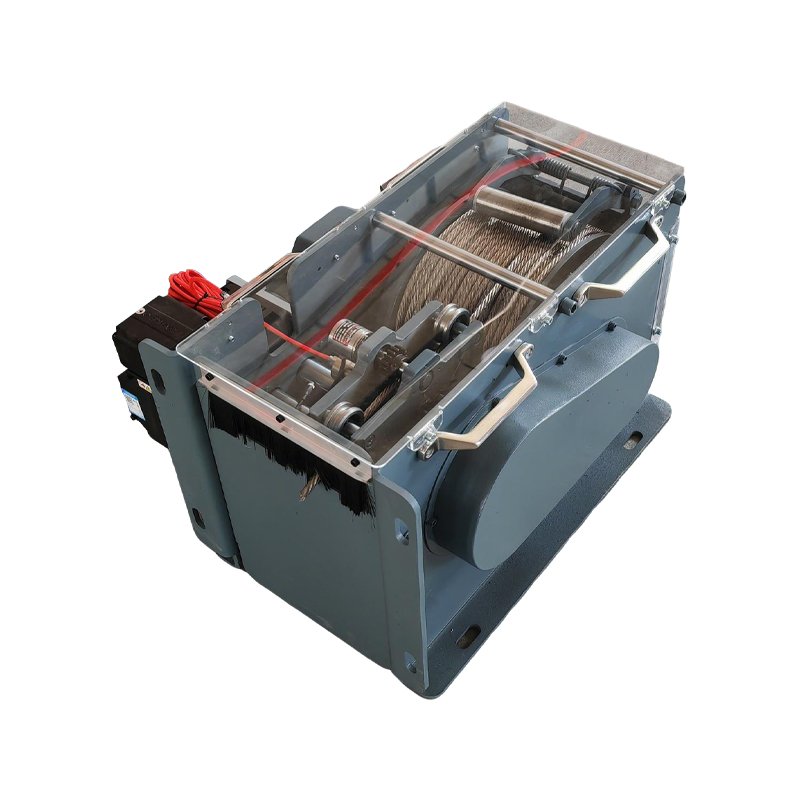

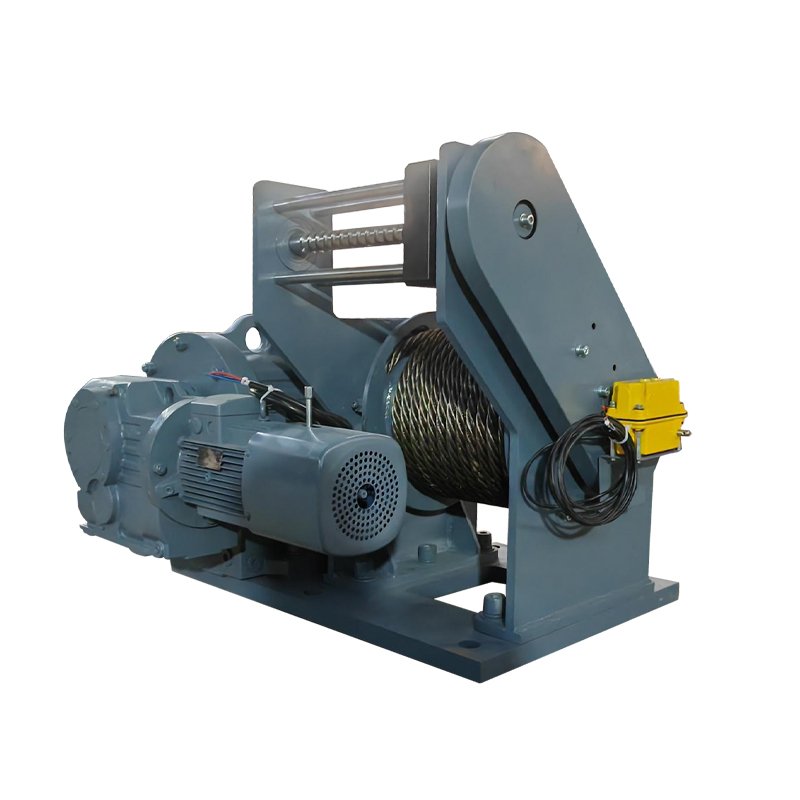

Designed specifically for wind turbine blade fatigue, pull-to-break, and structural integrity testing, our high efficiency electric winch delivers precise, repeatable pulling force in professional testing environments. Powered by a 7.5 kW variable frequency (VFD) motor with direct-drive worm gear reduction (561:1 ratio), this heavy duty electric cable winch provides ultra-precise speed control, integrated load cell monitoring, and synchronized multi-unit operation – making it the ideal electric tugger winch for wind blade certification and R&D labs worldwide.

With load capacities from 500kg to 30,000kg (30 tons) and 220–380V 3-phase power compatibility, this 3 phase electric winch combines industrial-grade reliability with advanced control features that meet the demanding requirements of wind energy testing standards.

Linkedin

Linkedin

Google +

Google +