How Long-Distance Traction Winches Enable 1000m+ Pipeline Inspection & Robotic Operations

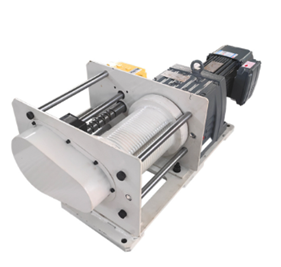

Custom Winch Systems for Reliable Cable Management in Oil, Gas & Municipal Applications

1. Why Long-Distance Traction Is a System-Level Challenge

In engineering applications, the difficulty of long-distance traction is not simply about whether sufficient pulling force is available. The real challenge lies in maintaining stable, controllable, and safe traction over extended distances. As distance increases, multiple risks are amplified simultaneously, including:

Accumulated Traction Resistance

As pulling distance grows, rope self-weight, friction at bends, and slope resistance accumulate continuously, placing higher demands on the drive system’s sustained output capacity and stability.

Limited Space and Installation Constraints

Pipeline diameters and working spaces are often restricted. Equipment must not only provide adequate traction force but also meet practical requirements for compact structure, portability, and installation efficiency.

High Risk from Traction Fluctuations

Any vibration, jerking, sudden stops, or rope jamming during traction may cause cameras, sensors, or robots at the front end to collide or become damaged. In worst cases, equipment may become stuck inside the pipeline, making recovery difficult and costly.

Multi-Dimensional Operating Requirements

Project requirements usually go far beyond simple “pulling weight.” They often involve speed control, rope length configuration, control methods, rope exit direction, and multiple levels of safety protection.

For these reasons, long-distance traction equipment should be regarded as an on-site solution platform, rather than a single-function actuator.

2. Design Logic and Configuration Key Points Based on Typical Projects

In pipeline inspection robot projects, a common requirement is to perform inspections over 300–400 meters inside pipelines with diameters of around 200 mm, while maintaining reliable retrieval and rescue capability in the event of equipment failure or obstruction.

Breaking down this type of application reveals several core objectives:

- Stable traction of approximately 100 kg-class loads, with sufficient safety margin over long distances

- Long rope length configurations while preventing tangling or disorder during winding

- Portable and mobile structure suitable for multi-point and high-frequency field operations

- Low noise and low vibration operation to minimize interference with inspection equipment and the working environment

- The ability to match traction force, speed, control mode, and safety protection precisely to project conditions

Based on these objectives, key design considerations for long-distance traction winches include:

Rope Selection Focused on Strength and Durability

High-temperature-resistant Kevlar ropes are often used to balance tensile strength, abrasion resistance, and safety, making them well suited for long-distance and high-friction conditions.

Lightweight and Portable Structural Design

Through structural optimization and material selection, overall weight is reduced while maintaining strength. Integrated carrying handles improve single-person handling and on-site relocation efficiency.

Rope Arrangement and Protective Structures to Reduce Jamming Risks

Spiral rope guiding mechanisms combined with protective covers help minimize tangling, rope jumping, and jamming during winding and unwinding, ensuring smoother and more reliable operation.

Drive System Emphasizing Stable Continuous Output

A carefully matched drive configuration ensures low noise, low vibration, and consistent traction output during extended operation, improving inspection stability.

Parameterized Customization for Different Projects

Key parameters such as traction force, rope length, speed, control method, and rope exit direction can be customized to meet diverse project requirements.

3. Recommended Collaboration Approach for Pipeline Inspection and Robotics Projects

For engineering projects, a more efficient cooperation model is to structure operating conditions clearly before equipment selection or customization, enabling faster solution matching and risk assessment.

Recommended basic information to provide includes:

- Pipeline type and diameter range

- Estimated total traction load (including cables, cameras, robots, and accessories)

- Target operating distance (e.g., within 200 m or 300–400 m)

- Priority objectives (portability, continuous operation, low noise, precise speed control, etc.)

- Industry and safety requirements (municipal, petrochemical, mining, nuclear, research institutions, etc.)

Once these factors are clarified, more targeted solution recommendations can be developed, such as:

- Whether a 100 kg-class traction configuration is sufficient or if a higher safety factor is required

- Equipment size and weight targets based on site layout and mobility frequency

- Control method selection (local buttons, remote control, or combined control)

- Whether additional protective, alarm, or interlock systems are needed to meet industry standards and redundancy requirements

This cooperation model can be summarized as:

The project owner provides operating conditions and goals; the equipment supplier delivers a platform-based configuration and an engineered solution.

Conclusion

If your project has the following characteristics:

- Pipeline distances reaching several hundred meters, requiring stable traction of cameras, inspection robots, or other devices

- Existing solutions suffering from rope jamming, insufficient distance, poor speed control, or low efficiency

- A need to improve professionalism, reliability, and delivery quality in long-distance pipeline operations

It is recommended to organize your operating parameters and project goals and submit them through the website contact channels. Configuration options can then be jointly evaluated based on real project conditions, helping to reduce on-site risks and significantly improve operational efficiency.