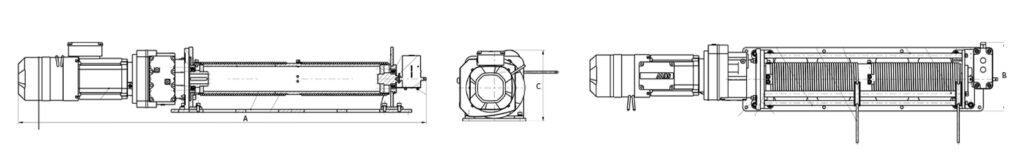

The double-rope inline electric winch is driven by an SEW gear motor, ensuring smooth operation with high efficiency and low noise. The stainless-steel housing makes the machine robust and durable while maintaining stable performance over long-term use. Equipped with a dual-rope synchronous lifting mechanism and a grooved drum, the winch offers easier and smoother operation. Combined with a variable-frequency control system, it allows flexible adjustments to meet diverse operational needs.

Design advantages:

-

SEW Gear Motor Drive: Provides reliable and stable power output, ensuring safe operation while improving overall efficiency.

-

Stainless-Steel Housing: Offers excellent corrosion resistance and durability, adapts to various working environments, reduces maintenance frequency, and extends service life.

-

Dual-Rope Synchronous Lifting: Ensures smooth and consistent lifting, reduces operational risks, and further enhances work efficiency.

-

Grooved Drum Design: Prevents rope tangling or loosening, keeps alignment neat, and improves operational smoothness.

-

Inline Structure: Compact footprint, especially suitable for space-constrained work sites, maximizing space utilization.

Linkedin

Linkedin

Google +

Google +