Electric Self Tailing Winch|Industrial Traction / Multi-Layer Winding / High-Stability Traction Solution

I. Product Overview

The electric self tailing winch is a highly reliable hoisting device specifically designed for industrial traction, lifting, positioning, and slideway assistance applications.

Through the structural combination of a rope groove drum and a reciprocating screw rope lay-out device, it ensures orderly wire rope winding even under multi-layer winding, large rope capacity, and long stroke conditions, completely eliminating issues such as rope tangling, rope squeezing, and groove jumping.

Driven by a variable-frequency braking motor, the equipment operates smoothly with low noise, suitable for continuous duty. With an IP56 protection rating, the entire unit ensures long-term stable operation in outdoor and demanding industrial environments.

Applications include: industrial traction, equipment retrieval, slide systems, work platforms, outdoor engineering, and similar scenarios.

II. Why Choose Electric self tailing winch for Industrial Traction?

In industrial traction systems, pulling power alone does not guarantee stability.

Conventional winches frequently suffer from rope tangling during multi-layer winding, directly causing:

Fluctuating traction resistance

Abnormal wire rope wear

Equipment impact and safety hazards

Electric self tailing winch employ mechanical structures for active rope management, ensuring the traction process consistently maintains:

Stable pulling force

Consistent speed

Even cable load distribution

These are fundamental requirements for long-term, stable industrial system operation.

III. Core Structure and Technical Advantages

1. Grooved Drum Design

Presets wire rope travel path

Prevents groove jumping and rope stacking

Reduces wire rope wear

️⃣ Reciprocating Screw Rope Guide

Synchronized with drum movement

Maintains order during multi-layer winding

Full control over rope payout/retraction

Driven by variable-frequency brake motor

Smooth starts/stops minimize impact

Adjustable speed adapts to diverse conditions

Low noise suitable for factory and lab environments

️⃣ Industrial-Grade Construction & IP56 Protection

High-strength chassis supports continuous operation

Dustproof and resistant to high-pressure water jets

Suitable for outdoor installation and all-weather operation

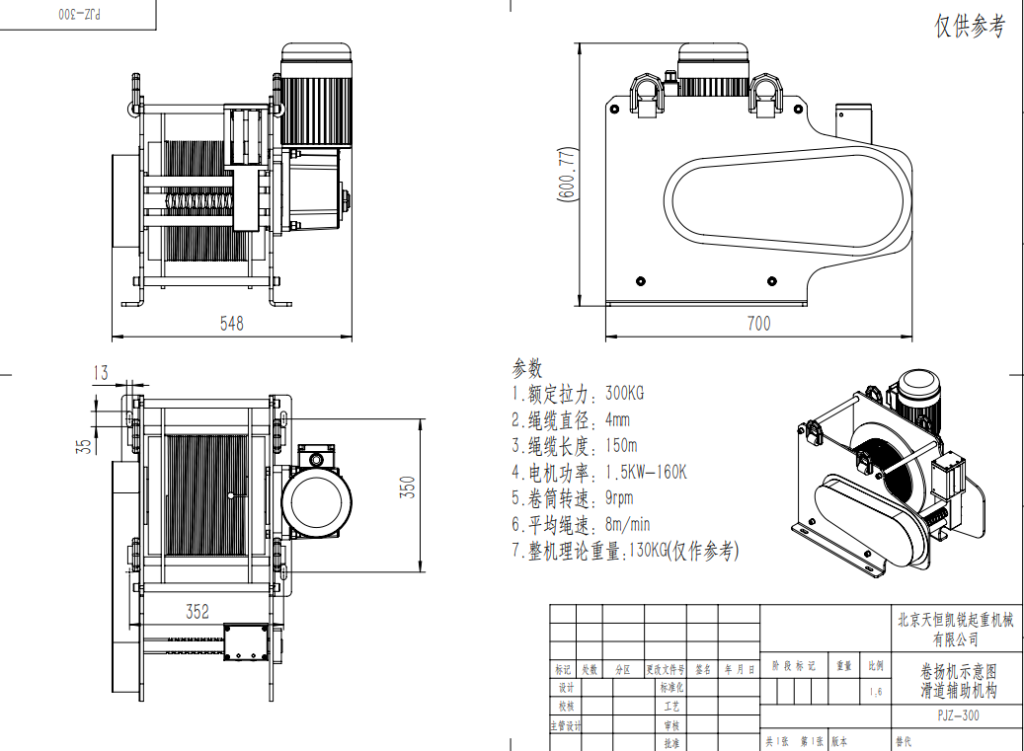

IV. Typical Technical Parameters

Common configuration examples below, customizable per requirements:

Model: 300 KG

Rated Tensile Force: 300kg

Wire Rope Diameter: 4mm

Rope Length: 150m

Motor Power: 1.5kw

Drum Speed: 9rpm

Average Rope Speed: 8m/min

Theoretical Total Weight: Approx. 130 kg

V. Application Scenarios

Industrial equipment traction and retrieval

Slideway/guide rail auxiliary mechanisms

Automated tooling platform movement

Multi-layer winding and high rope capacity applications

Outdoor engineering traction and positioning systems

VI. Customization Support

This series of electric self tailing winch supports customization based on actual operating conditions, including but not limited to:

Rated load

Rope capacity

Rope payout/retrieval speed

Motor and voltage configuration

Travel limit switches

Mounting structure types

Suitable for equipment integration, engineering projects, and system integration applications.

FAQ|Customer Questions

Q1: What is the fundamental difference between electric self tailing winch and standard winches?

A: electric self tailing winch feature an active rope-laying mechanism that maintains orderly wire rope arrangement during multi-layer winding. Standard winches are prone to rope tangling, resulting in compromised stability and safety.

Q2: Does multi-layer winding affect traction accuracy?

A: No. The reciprocating screw rope-laying mechanism ensures uniform arrangement of each rope layer, providing stable traction resistance suitable for precision applications.

Q3: Is it suitable for long-term outdoor use?

A: Yes. With an IP56 protection rating, the unit operates reliably in outdoor environments exposed to rain and dust.

Q4: Is the traction speed adjustable?

A: Yes. Equipped with a variable frequency drive system, the operating speed can be flexibly adjusted according to operational requirements.

Q5: Does it support non-standard customization?

A: Yes. Customization is available for pulling force, rope capacity, speed, voltage, and mounting methods based on project needs.