Stainless Steel Electric Winch Solutions for Marine Inspection and Scientific Research Operations

I. Applicable Scenarios

In marine inspection, oceanographic research, and coastal environmental monitoring operations, inspection instruments typically require a winch system for deployment, retrieval, and depth control.

These operations share the following common characteristics:

- Long-term exposure to high humidity and salt spray environments

- Winches are predominantly installed outdoors

- High-value inspection equipment demands stringent operational safety requirements

Extended operational cycles with frequent continuous equipment operation

Conventional industrial winches often struggle to maintain long-term stable performance in such environments.

II. Analysis of Typical Issues

Common challenges encountered in actual projects include:

1. Inadequate rain and moisture resistance

Rainwater and humidity ingress can cause motor and electrical component failures.

2. Lack of traction monitoring capabilities

Real-time force data for detection instruments is unavailable, creating operational risks.

3. Inadequate installation adaptability: Excessive size or weight hinders mounting on experimental vehicles or mobile platforms.

III. Solution Design Approach

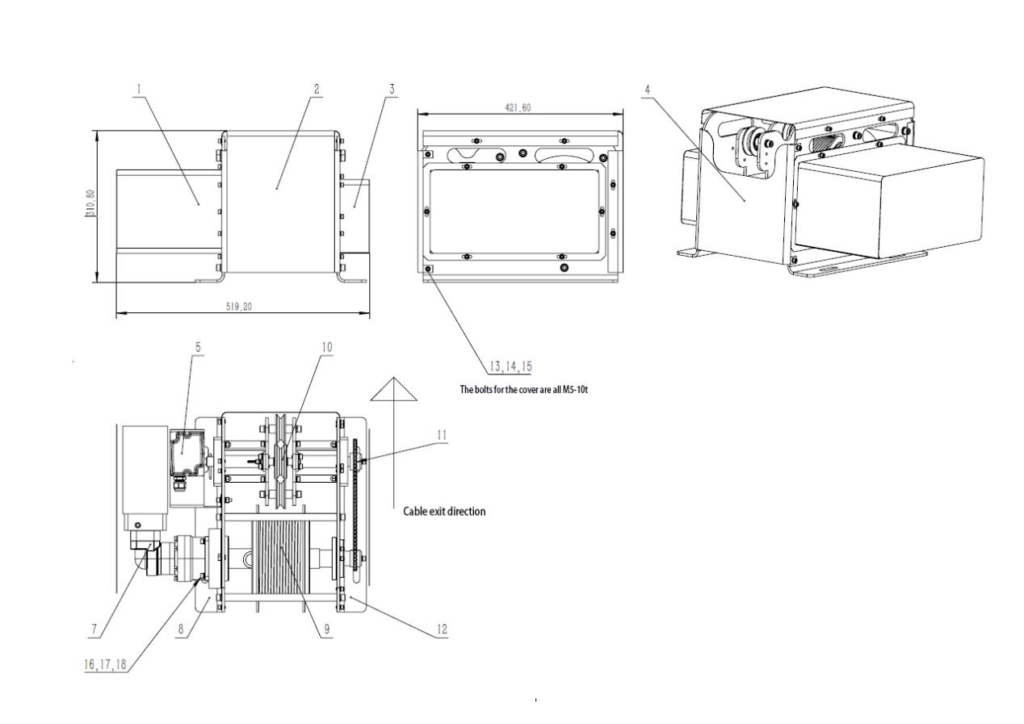

For marine inspection scenarios, the following stainless steel electric winch solution is proposed:

1. Stainless steel main structure

The winch body utilizes stainless steel to enhance corrosion resistance at the material level, effectively withstanding salt spray and humid environments while extending equipment lifespan.

2. Rainproof and Moisture-Resistant Structure

Equipped with a rain cover to minimize the impact of rainwater and humidity on the motor and electrical systems, suitable for long-term outdoor operation.

3. Compact and Lightweight Design

Through optimized structural design, volume and weight are reduced while maintaining strength, facilitating installation on test vehicles or mobile platforms.

4. Real-Time Towing Load Monitoring

Integrated tension sensors continuously monitor towing forces, enhancing safety and controllability during instrument deployment and retrieval.

5. Multi-Angle Adaptability

The front bracket supports 360° rotation, allowing flexible adjustment of towing direction to meet on-site operational requirements.

IV. Technical Specifications

Rated Tensile Force: 20kg

Wire Rope Length: 15m

Wire Rope Diameter: 5mm

Total Weight: ≤45kg

Standard Configuration: Stainless steel housing, rain cover, tensile force sensor

V. Solution Advantages Summary

Suitable for long-term operation in highly corrosive marine environments

Reduces maintenance frequency and operational costs

Enhances inspection task safety

Compatible with multiple inspection and research platforms

FAQ

Q1: Is this solution limited to marine environments?

It is suitable not only for marine inspections but also for coastal, high-humidity, and corrosive industrial settings.

Q2: Can the tensile force be customized?

Adjustments can be made based on the weight of inspection equipment and operational requirements.

Q3: Does it support long-term outdoor installation?

Yes. The stainless steel construction combined with rainproof design is specifically engineered for outdoor conditions.