Steel Strand Laying Operations During Nuclear Island Construction at Nuclear Power Plants

— Case Study Solution for Horizontal Towing Combination Winches

I. Project Background

During the construction phase of a nuclear power plant's containment structure, steel strands are extensively used for structural erection, prestressing system installation, and temporary pulling operations. Such work typically occurs in:

- Areas within the containment structure or near the containment vessel

- Spaces with dense scaffolding and limited access

- Narrow, elongated passageways with complex pulling routes

The steel strand deployment process involves long distances, heavy loads, and extremely high demands for tension continuity, pulling stability, and safety redundancy. Traditional methods using single winches or manual rope release are increasingly inadequate for meeting safety and quality requirements in nuclear construction scenarios.

II. Operational Pain Points and Technical Challenges

1️⃣ Passive rope release leads to slackening and tangling

During steel strand deployment, "one-end pulling with simultaneous rope release at the other end" is often required. If tension at the release end is uncontrolled, it easily results in:

- Reel slackening

- Layer collapse

- Strand knotting or derailing

2️⃣ Difficulty maintaining stable tension during long-distance pulling

The extended pulling paths and multiple turning points within the nuclear island cause tension fluctuations that:

- Induce impact loads

- Compromise strand placement accuracy

- Increase construction risks

3️⃣ Nuclear construction demands exceptionally high equipment reliability

Equipment must meet:

- Long-term continuous operation

- Controllable failure modes

- Clear mechanical and safety verification basis

III. Solution Overview

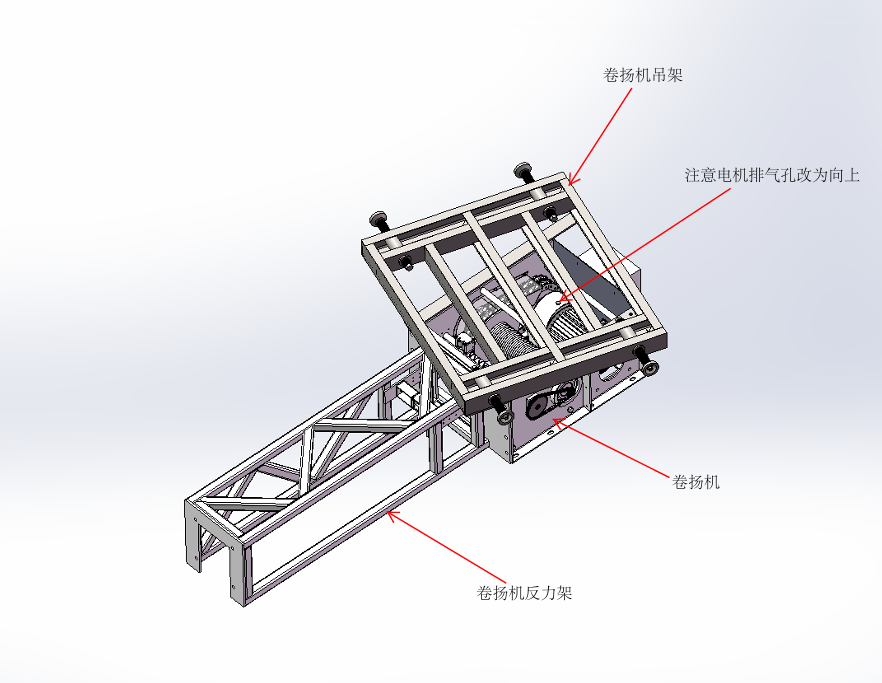

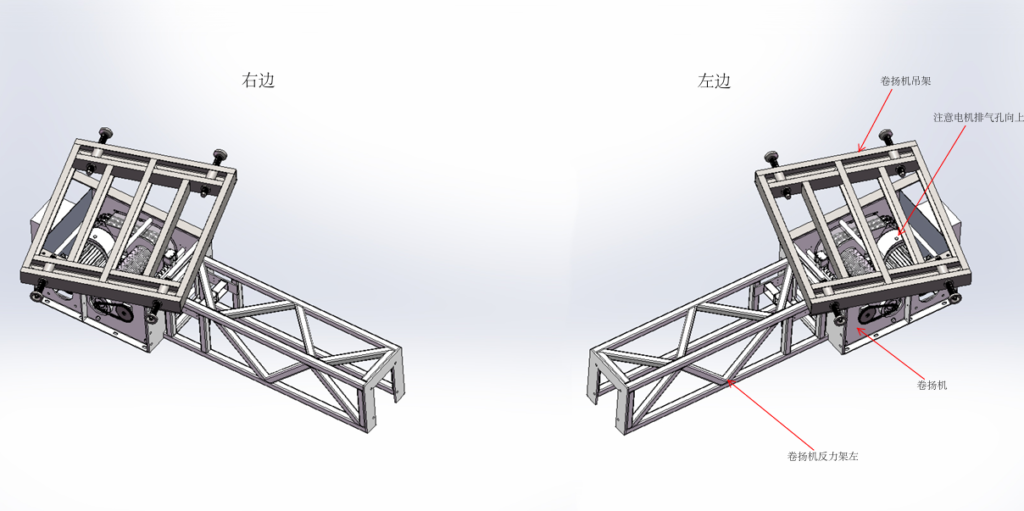

To address these issues, the project employs a horizontal traction combined winch solution: two winches are grouped, with one actively pulling and the other passively releasing rope, forming a closed-loop tension control system.

Operating Mode Description

- Mode One

- Winch A: Active rope retrieval (steel strand traction)

- Winch B: Passive rope release (controlled tension output)

- Mode Two (Reverse Construction)

- Winch B: Active

- Winch A: Passive

This mode is suitable for reciprocating construction operations such as steel strand laying, adjustment, and retrieval.

IV. Key Technical Parameters and Operating Conditions

The parameters in this section directly support equipment selection and safety verification for nuclear island construction in nuclear power plants, serving as critical engineering references for this case.

1. Key Technical Parameters

| Item | Technical Parameter |

|---|---|

| Hoist Rated Load | 3.5 tons |

| Wire Rope / Strand Diameter | Φ12 mm |

| Drum Linear Speed | 14 m/min |

| Working Class | M5 |

| Rated Voltage | 380V / 3Ph / 50Hz |

| Installation Type | Horizontal traction, equipped with independent reaction frame |

2. Operating Environment Conditions (Nuclear Construction Adaptation)

- Ambient Temperature: -20 to +40 °C

- When ambient temperature falls below -10 °C, it is recommended to:

- Preheat the gear reducer before startup

- Or replace with low-temperature lubricating oil

- When ambient temperature falls below -10 °C, it is recommended to:

- Relative Humidity: ≤ 85%

- Altitude: ≤ 1000 m

- Operating Environment:

- No water spray or dripping

- No severe vibration or impact

- This parameter set is highly compatible with the semi-enclosed construction environment inside the nuclear island.

V. Reaction Frame and Wire Rope Load Analysis

1️⃣ Wire Rope Tension Calculation

Maximum working load of the winch is 3.5 tons: F = 3500 × 9.8 = 34300 N

2️⃣ Wire Rope Cross-sectional Area Calculation

Wire rope diameter: d = 12 mm

Cross-sectional area: S = π × (d/2)² = 3.14 × (12/2)² = 113.04 mm²

3️⃣ Working Stress of Wire Rope

σ = F / S = 34300 / 113.04 ≈ 303.43 MPa

4️⃣ Safety Stress Verification (Nuclear Construction Redundancy)

Considering nuclear engineering safety standards, apply a 0.8 safety factor:

σ_s = 0.8 × 303.43 ≈ 242.74 MPa

✅ Conclusion: The wire rope operates within safe stress limits under these conditions, meeting continuity, stability, and safety redundancy requirements for nuclear island strand installation.

5️⃣ Significance of Reaction Frame Design

Reaction frames serve to:

- Counteract horizontal traction reaction forces

- Safely transfer loads to structural or scaffolding systems

- Prevent localized stress concentration

- Ensure stable strand pulling direction and tension

This is the key reason why the integrated "hoist + reaction frame" solution is mandatory for nuclear island construction.

VI. Field Application Results

During actual nuclear island construction, this solution achieved:

- ✔ Stable tension throughout the entire strand laying process

- ✔ No slack, tangling, or knotting

- ✔ Controllable construction pace with significantly reduced safety risks

- ✔ Meets nuclear power engineering requirements for equipment reliability

VII. Summary of Typical Application Scenarios

- Towing within confined spaces of nuclear power plants

- Long-distance reciprocating towing of steel wire ropes/strands

- High-safety-grade industrial and energy engineering projects

VIII. Kailude - Custom Manufacturer of Engineering-Grade Industrial Winches

Beijing Tianheng Kairui Hoisting Machinery Co., Ltd., operating under the brand Kailude, is an engineering-grade industrial winch custom manufacturer. With our own factory, professional engineering team, and deep customization capabilities, we are committed to providing comprehensive industrial winch solutions for projects ranging from small to large-scale globally. We ensure exceptional quality, rapid response, and on-time delivery, maximizing your project value through continuous innovation and full-service support. We can provide you with the most reliable product solutions.

FAQ

Q1: Why is a single winch unsuitable for nuclear power construction?

A: A single winch cannot simultaneously control traction and rope tension, increasing the risk of rope entanglement.

Q2: Does the 3.5-ton load capacity include a safety margin?

A: Load calculations have been verified with a 0.8 safety factor, meeting nuclear construction requirements.

Q3: Is 14 m/min speed too slow?

A: Nuclear construction prioritizes controllability; this speed facilitates precise deployment.

Q4: Is a reaction frame mandatory?

A: Yes. The reaction frame is critical for system safety and structural integrity.

Q5: What is KLD's customization process?

A: Standard steps include requirement discussion, operational analysis, solution design, parameter confirmation, manufacturing testing, and delivery support.

Q6: Does KLD provide after-sales and technical support?

A: Yes, including selection guidance, installation support, and operational technical consultation.

Q7: What aspects of KLD do customers typically recognize?

A: Engineering comprehension, solution reliability, communication efficiency, and delivery consistency.