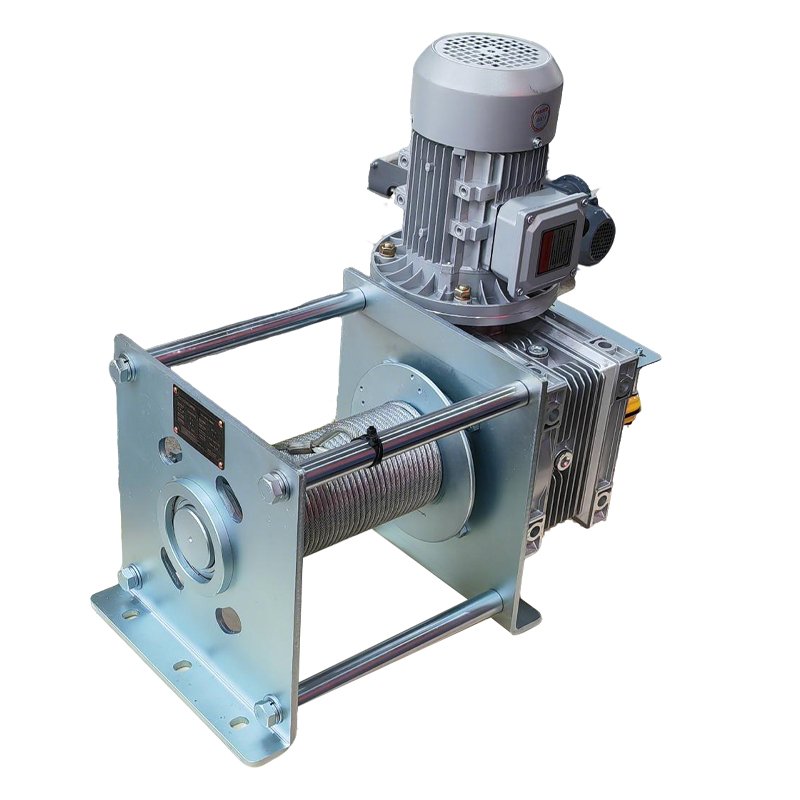

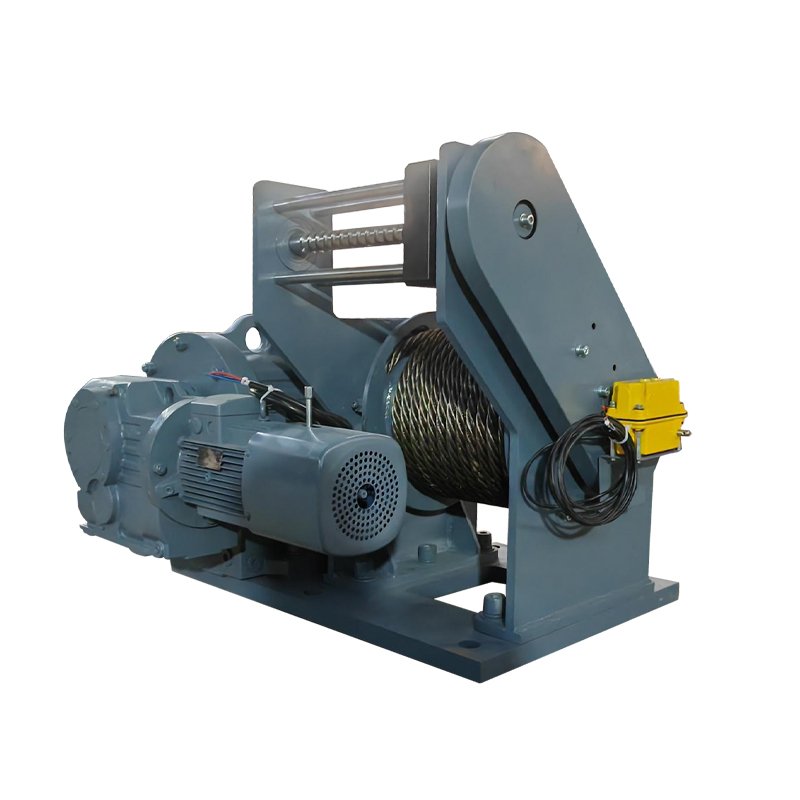

This long-stroke portable electric winch is custom-engineered for demanding pipeline inspection and maintenance tasks, offering an impressive 300–400 meter travel range. With a rated pulling force of 100kg (fully customizable up to 8000kg), it reliably deploys inspection equipment into 200mm-diameter pipelines and provides extended traction support for troubleshooting, repairs, or emergency recovery. The lightweight electric winch design includes a convenient carry handle for effortless transportation, while the high-temperature-resistant Kevlar rope and screw-type rope guider ensure smooth, tangle-free operation over long distances. Powered by a quiet right-angle motor, this quiet electric winch delivers stable performance with minimal noise – perfect for sensitive or confined environments.

Long-Stroke Portable Electric Winch

-

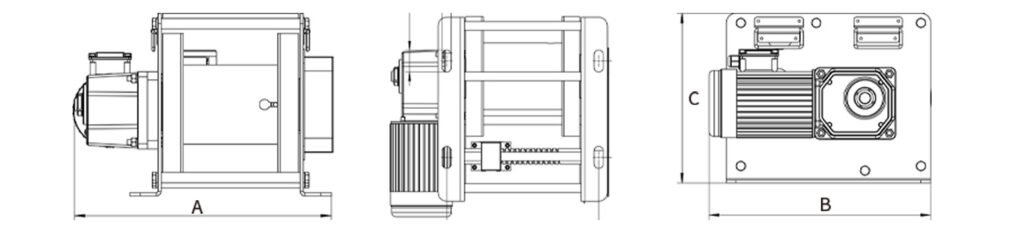

A two-dimensional drawing clearly presents the equipment’s layout and core structure.

Key Features & Advantages

- Extended Long-Range Capability: True long rope electric winch performance with 300–400m travel – enables deep pipeline access and reliable long-distance traction when equipment gets stuck.

- Ultra-Lightweight & Portable: Compact body with integrated carry handle makes this lightweight electric winch easy to transport and reposition on-site, boosting operational efficiency.

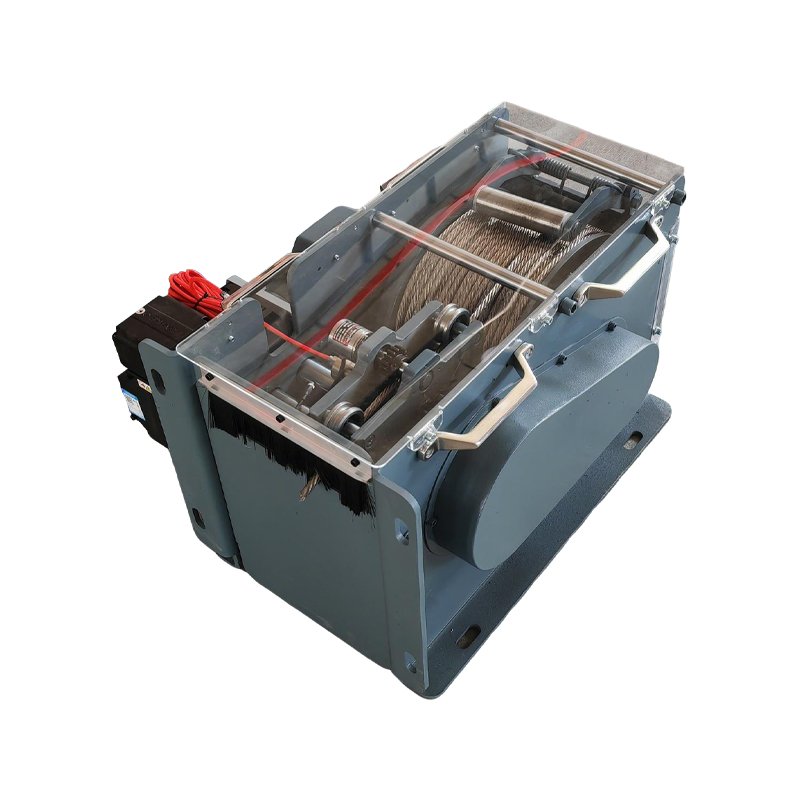

- Superior Rope Management: Screw-type rope guider plus protective cover keeps the high-temperature-resistant Kevlar rope neatly arranged, preventing tangling, jamming, or damage during extended pulls.

- Quiet & Efficient Drive: Right-angle silent motor provides steady power output with exceptionally low noise – a genuine quiet electric winch that enhances comfort and reduces disturbance in working areas.

- Robust Component Protection: Top guard plate shields internal parts from external impacts, ensuring long-term durability in harsh conditions.

- High Customizability: Load capacity, voltage (220-380V), speed, rope type, and other parameters can be tailored to exact project requirements.

- Enhanced Safety & Reliability: Stable operation, protective features, and lightweight construction combine for confident performance in critical applications.

Technical Specifications

Parameter Specification Travel / Rope Capacity 300–400 meters Rated Pulling Force 100kg (customizable up to 8000kg) Rated Voltage 220V / 380V Motor Type Right-angle silent motor (high efficiency) Rope Material High-temperature-resistant Kevlar Rope Guidance Screw-type guider with protective cover Design Features Lightweight body with portable carry handle, top guard plate Pulling Speed Customizable (typically 8-15 m/min) Noise Level Ultra-low noise (≤65dB) Protection Rating IP54 standard (higher ratings customizable) Operating Temperature -10°C to +60°C (Kevlar rope suitable for higher temps) Safety Devices Overload protection, emergency stop, rope protection Model:100KG Motor power: 0.4 kW Rated tension: 100 kg Rope diameter: 4 mm Drum speed: 12 rpm Average rope speed: 7 m/min Rope length: 400 m Model:100KG A(Length):650mm B(Width):515mm C(Height):350mm

Applications

- Pipeline Inspection & Maintenance (Primary): Custom-designed for Huibo Robotics – deploys cameras, sensors, or tools deep into 200mm pipelines for inspection, cleaning, and fault location.

- Mining & Underground Operations: Long-distance traction and recovery in tunnels and wells where portability and quiet operation are essential.

- Construction & Engineering: Horizontal pulling and equipment positioning on sites requiring extended reach and easy relocation.

- Special & Rescue Equipment: Emergency extraction of stuck devices or personnel support – reliable portable electric winch performance when rapid response matters most.

Why Choose Our Long-Stroke Portable Electric Winch?

- Unmatched Reach & Mobility: 300–400m capacity in a truly lightweight electric winch package – far more practical than bulky traditional systems.

- Quiet, Reliable Performance: The advanced silent motor makes this a standout quiet electric winch that operates smoothly without disrupting work environments.

- Built for Tough Jobs: Kevlar rope, protective guider, and guard plate ensure durability and safe long rope electric winch operation in challenging pipeline and rescue scenarios.

- Fully Tailored Solution: Custom configurations let you optimize this portable electric winch for voltage, load, and specific project demands.

Need a reliable long-distance traction solution for pipeline work? Contact us today for customization options and pricing!

Global shipping and dedicated technical support included.

Discover more about our long-stroke portable electric winch series – reach out now.her design and configure the product’s protective performance, durability, safety, and other aspects. -

get a quote

Linkedin

Linkedin

Google +

Google +