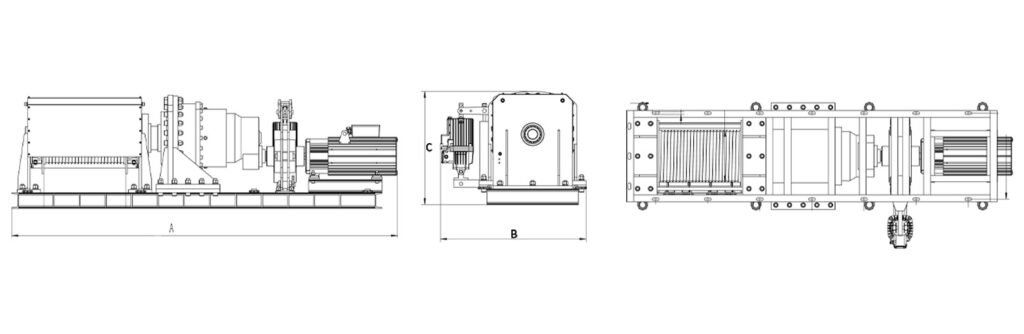

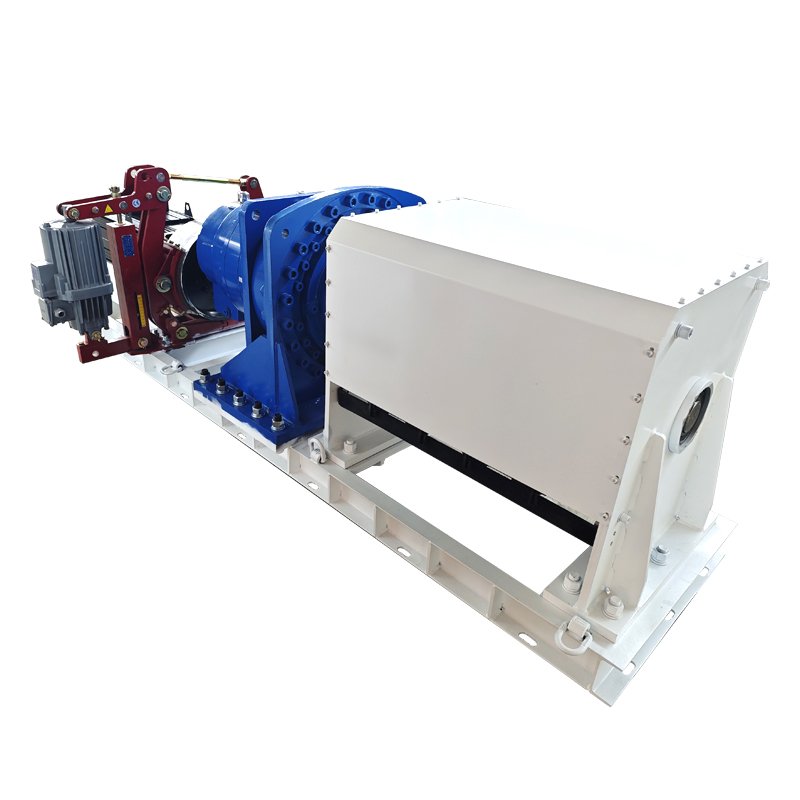

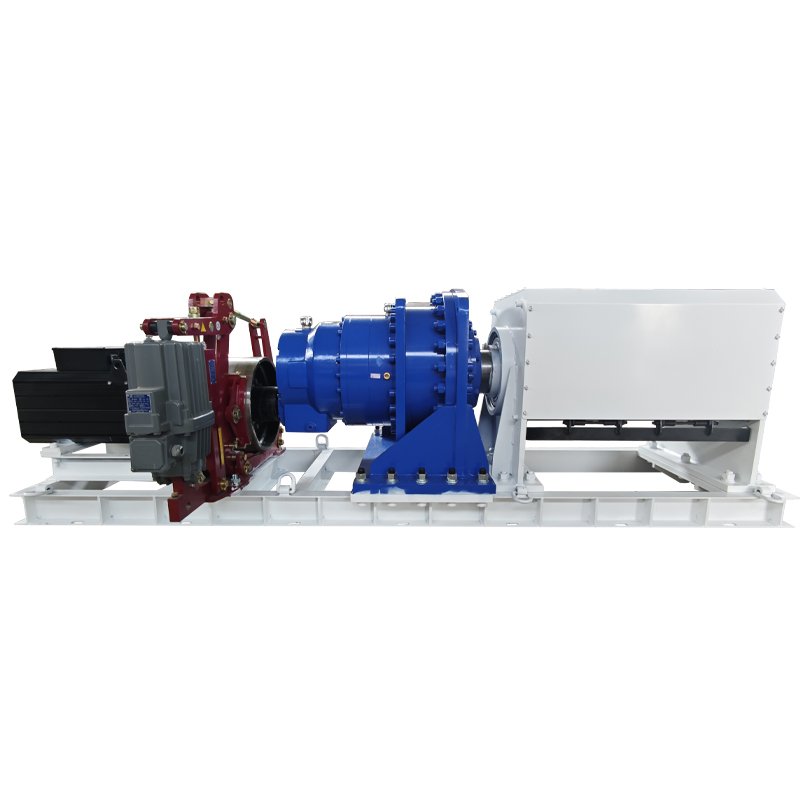

This large servo industrial winch is equipped with a servo motor with an absolute encoder, enabling precise position control, speed control, and constant tension output. It effectively improves operational efficiency while reducing labor consumption. The entire machine adopts a safe and efficient design that not only ensures operator safety but is also widely applicable to material handling, traction, and lifting in various industrial automation scenarios. Manufactured with high-quality materials and advanced processes, the equipment delivers stable and reliable performance, durability, and long-term value with efficient support for users.

Design advantages:

-

High-power servo motor combined with encoder provides precise control and significantly improves efficiency.

-

Hydraulic drum brake ensures safe and efficient operation, protecting operator safety.

-

Planetary gear reducer with an ultra-high transmission ratio delivers high efficiency and longer service life.

-

Single-layer grooved drum achieves precise positioning, ensuring more accurate operation.

-

Spring-type rope presser prevents rope disorder during slack, ensuring stable and reliable operation.

Linkedin

Linkedin

Google +

Google +