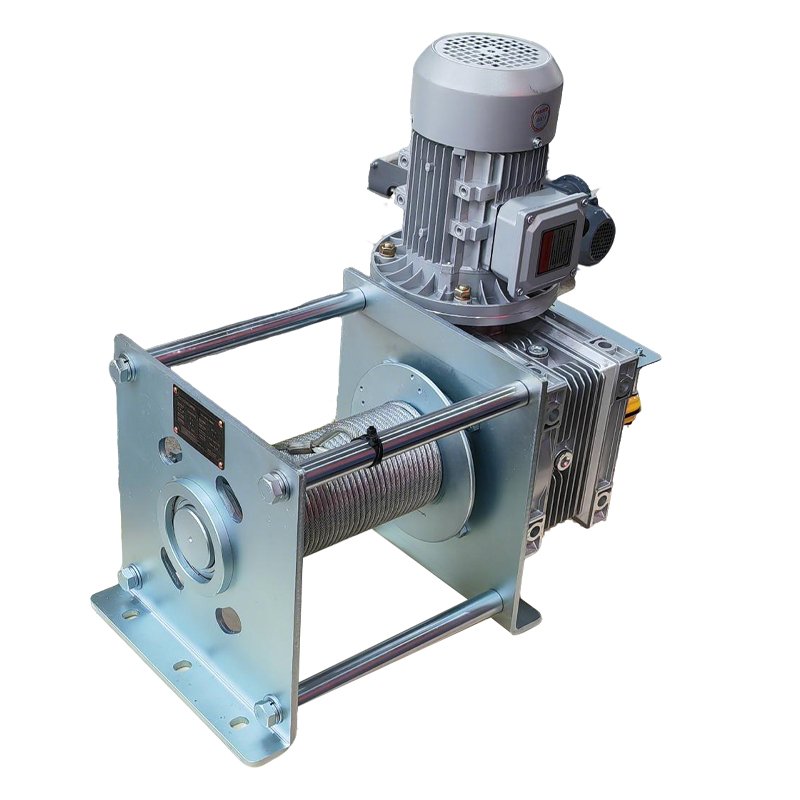

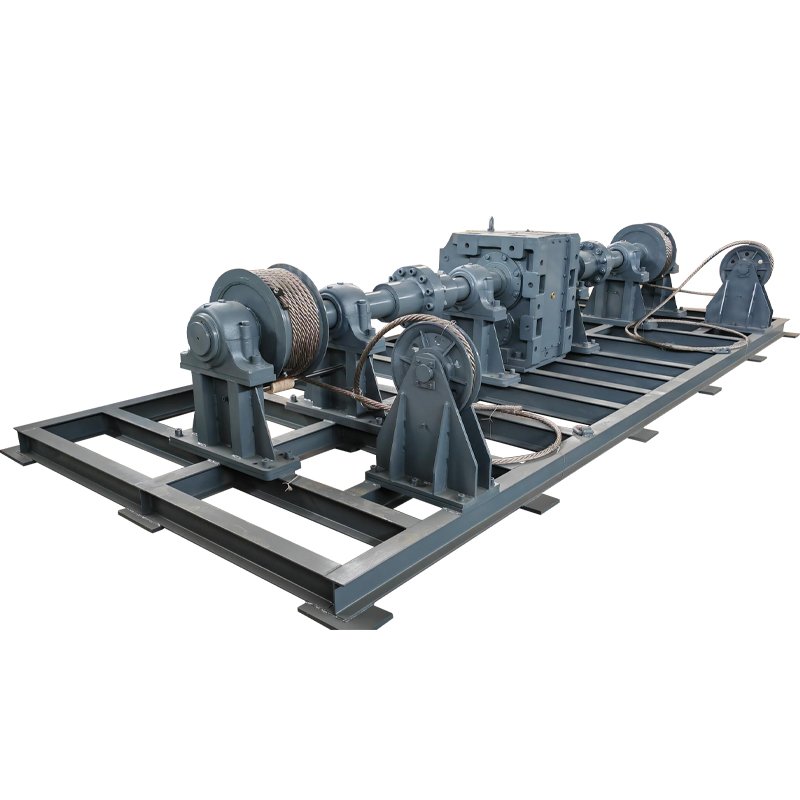

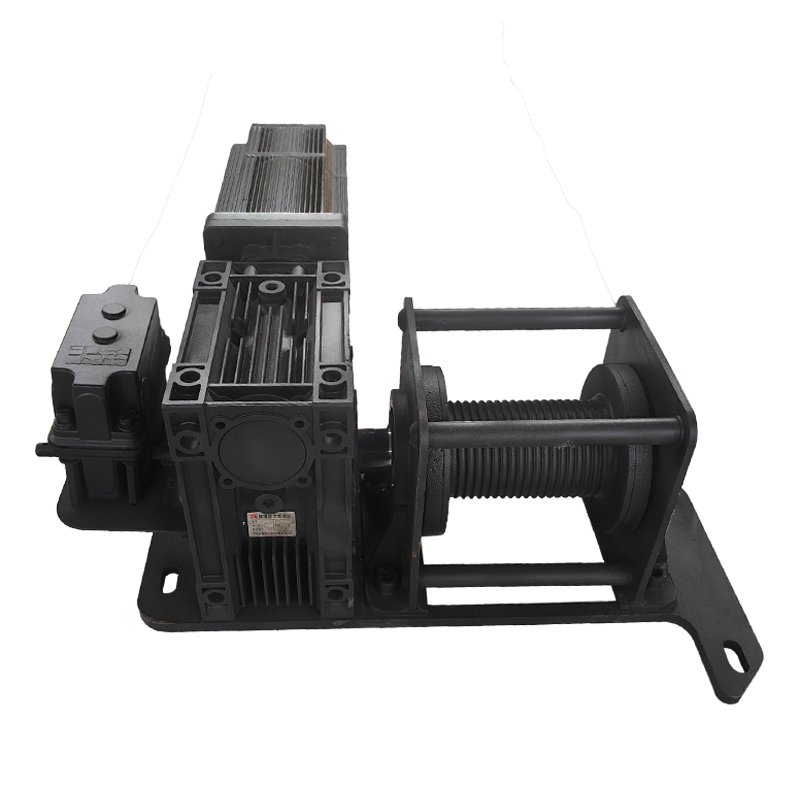

This servo winch is specially designed for chandelier frame applications, equipped with advanced integrated servo motor technology that allows flexible adjustment of lighting height as needed, creating a more comfortable and adaptable lighting effect.

• Easy and convenient height adjustment to meet the lighting needs of different scenarios.

• Can be directly driven via computer or control terminal, improving operational efficiency.

• Stable and reliable servo control technology ensures safety and durability.

Design advantages:

-

Made of aluminum alloy material with a lightweight structure, making installation and use more convenient.

-

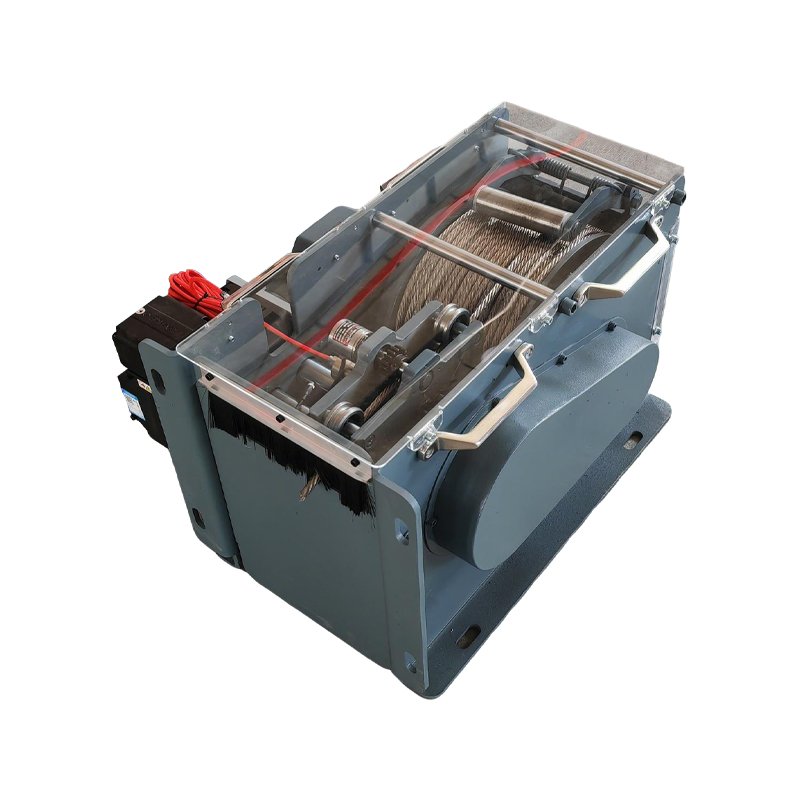

Supports multi-unit linkage control with a modularized electric box design that divides a large electric box into multiple smaller ones, reducing size, distributing weight more evenly, and preventing the chandelier frame from being overloaded.

-

Built-in PLC control system allows operation via computer or control terminal, with a simple and intuitive interface for precise adjustment of chandelier height and operating speed.

-

Supports 485 communication, enabling device connection to a touchscreen and networked control through the Modbus TCP protocol.

Linkedin

Linkedin

Google +

Google +