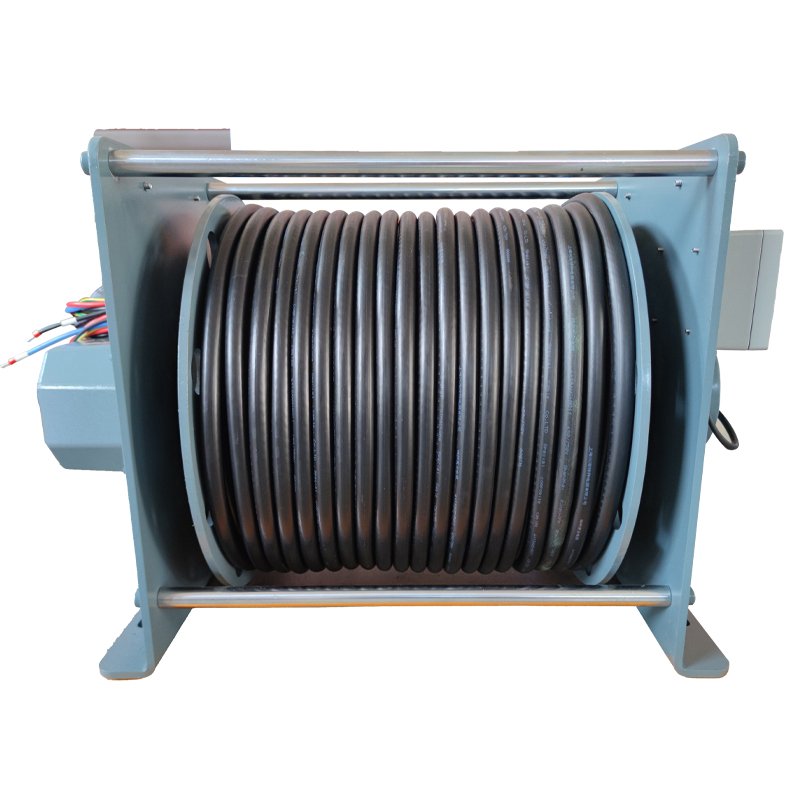

The stage wire hoist is a high-efficiency and safe lifting device designed specifically for theatrical environments, serving as a critical component of stage machinery systems. It enables flexible spatial arrangements and creates impressive visual effects for stage performances.

The winch can be customized according to cable retrieval speed, rope length, and operating mode, and is compatible with both single-phase and three-phase AC power to meet diverse user requirements.

Design advantages:

-

Dual-brake motor drive: Ensures safe operation even under extreme conditions, effectively reducing accident risks.

-

Grooved drum design: Prevents wire rope slippage and derailment, providing precise control.

-

Mechanical height limiter: Allows flexible upper and lower limit settings, effectively controlling the operating range and reducing accident risks.

-

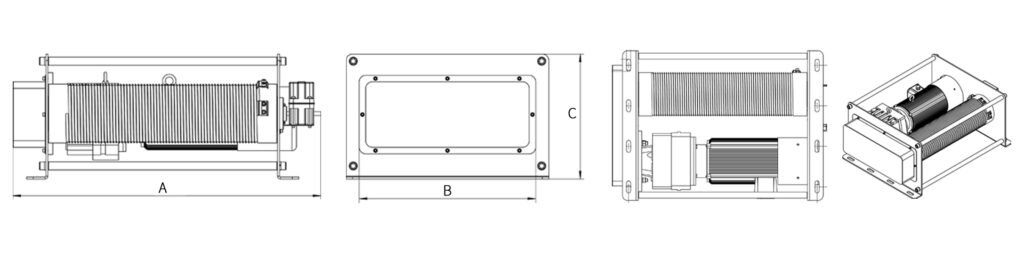

Parallel-structure layout: Compact and aesthetically designed, easy to install and maintain, occupies minimal space, and adapts to various installation environments.

Linkedin

Linkedin

Google +

Google +