1. Why Acid Pickling Workshops Need Dedicated Lifting & Traction Equipment

In the steel and non-ferrous metals processing industry, acid pickling workshops play a critical role in removing surface scale, rust, and impurities from workpieces — an indispensable step in the entire production flow.

Vertical lifting and horizontal traction of workpieces run through multiple processes, and the operating efficiency and safety of these movements directly determine the overall performance of the pickling production line.

Therefore, pickling workshops demand equipment with the following key characteristics:

- High efficiency, suitable for high-takt-time production

- Long travel distance, meeting requirements for deep tanks and extended traction

- Strong corrosion resistance, adapted to acidic and alkaline environments

- High safety, minimizing accident risks

Conventional general-purpose winches can no longer meet these demands. High efficiency heavy duty electric winches specially designed for pickling environments have become the mainstream upgrade choice in the industry.

2. Main Problems of Traditional Winches in Acid Pickling Workshops

- Slow lifting speed, seriously restricting pickling efficiency

Most standard electric winches operate below 50 m/min. In long-travel pickling lifting or cross-bay traction tasks, each cycle takes too long — a major bottleneck for workshop capacity. - Limited travel distance, unable to serve large-scale pickling lines

Traditional models usually have rope capacity under 200 meters. For large workshops or multi-station layouts, frequent intermediate transfers are required, reducing efficiency and increasing operational risks. - Prominent safety hazards in pickling environments

High humidity, strong corrosiveness, and heavy dust make ordinary equipment prone to over-winding and over-travel due to lack of precise limit control and reliable braking. - Poor corrosion resistance and short service life

Motors, gearboxes, and electrical components without special protection corrode quickly in acid mist, resulting in high failure rates and expensive maintenance.

3. Application Advantages of High Efficiency Heavy Duty Electric Winches in Pickling Workshops

- High-speed operation dramatically improves pickling productivity

Advanced models achieve line speeds up to 120 m/min — more than double the efficiency of conventional equipment — perfectly suited for long-travel, high-frequency lifting and traction tasks. - Long-travel design matches complex pickling process flows

With extended drum structures, high capacity electric winches offer rope capacities up to 500 meters, enabling single-pass deep-tank lifting and long-distance traction while eliminating intermediate handling. - Corrosion-resistant structure purpose-built for pickling environments

Full-machine anti-corrosion coatings combined with sealed protection for critical electrical and transmission components effectively resist acid mist, moisture, and dust. - Multiple safety features ensure reliable operation

Equipped with variable frequency braking systems + mechanical travel limiters for smooth start/stop and precise control, preventing over-travel and enhancing overall job safety.

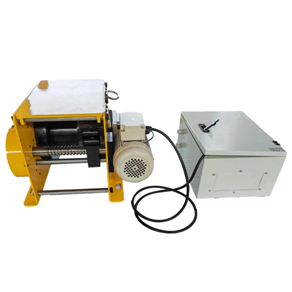

4. Core Configuration of High Efficiency Electric Winches for Acid Pickling

● Variable frequency braking motor

Enables precise speed control and rapid, smooth stopping — meeting dual requirements of smoothness and safety.

● Hardened gear reduction system

Strong load capacity and stable performance, ideal for continuous high-intensity pickling operations.

● Mechanical travel limit device

Adjustable upper and lower limits ensure safe, controlled lifting and traction throughout the production line.

● Long-travel drum design

Up to 500 meters rope capacity, perfectly matching large-scale pickling workshops and extended traction needs.

5. Real Value Delivered by the Solution

✔ Significantly increase overall pickling line efficiency

Shorter cycle times unlock greater workshop capacity.

✔ Greatly reduce safety accident risks

Multi-layer protection enhances operational reliability.

✔ Lower long-term maintenance costs

Superior corrosion resistance extends equipment life and reduces breakdowns.

✔ Ensure consistent product quality

Smooth operation minimizes workpiece impact and potential quality issues.

6. Customizable Electric Winch Solutions for Various Pickling Conditions

We offer fully tailored configurations to match different workshop requirements, including:

- Customized lifting & traction speed

- Customized rope capacity and travel length

- Rated load capacity selection

- Voltage and power supply adaptation

- Enhanced corrosion-proof or high-temperature resistant versions

This ensures perfect integration with your specific acid pickling production line.

Conclusion: Choosing the Right Electric Winch Is the Key to Efficiency Improvement

As the pickling industry continues moving toward higher efficiency and greater safety, high efficiency heavy duty electric winches with long travel capability have become the essential direction for lifting and traction equipment upgrades in acid pickling workshops.

Through high line speed, large capacity long drum design, and dedicated corrosion-resistant structure, this solution effectively addresses the low efficiency, insufficient safety, and short lifespan issues of traditional equipment — delivering long-term, stable performance for modern pickling production lines.