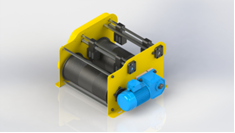

When your project needs reliable pulling and controlled pay-in/pay-out without the weight and bulk of a traditional steel unit, an aluminum-alloy lightweight winch is the sweet spot. It delivers the essentials—torque, controllability, and safety—in a compact package that’s easier to mount, move, and maintain.

Why aluminum-alloy for a lightweight winch?

- Low weight, easier installation

Aluminum-alloy housings and brackets cut mass dramatically, so one or two techs can position the unit without special lifting gear.

- Corrosion resistance out of the box

Anodized/treated aluminum plus stainless fasteners (optional) help in outdoor and coastal use. For harsher sites, you can still mix in stainless accessories or a coated cabinet.

- Tight-space friendly

Short motor/gearbox stack and compact drum geometry make it fit racks, cabinets, mobile rigs, and test benches. - Smooth, predictable control

Standard models support forward/reverse, emergency stop, and limit protection; you can add VFD, pendant/wireless control, and encoder read-outs for length/speed.

Typical use cases

- Test benches & fixtures: precise rope feed for setup, calibration, and durability runs.

- Instrument deployment: neat rope pay-out for sensors, probes, or tethers in labs and field rigs.

- Light equipment handling: guided pulls in maintenance bays and production lines.

- Compact mobile systems: where moving the winch between stations is part of the workflow.

Core features you can expect

- Aluminum-alloy frame & mounts for reduced weight

- Optimized rope outlet to keep feed smooth and reduce tangling

- Protected controls: pendant as standard; control panel or wireless as options

- Customizable drum/rope: groove pattern, rope diameter, length, and storage can be tailored

- Service access: clear terminal labeling, maintainable bearings/gearbox, optional spares kit

Spec ranges (indicative; built to your order)

- Rated pull: light-duty range for compact handling (spec to your load & duty)

- Rope speed: tuned via gear ratio or VFD; steady, low-noise running

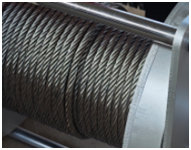

- Rope package: small-diameter wire or synthetic; 3–5 mm common on lightweight builds

- Capacity: compact reels for short travel; can scale with multi-layer storage and level-wind if you need longer runs

- Power: 3-phase is standard; selected ratings can be adapted for single-phase sites

- Controls: pendant → panel → wireless; optional encoder for length/speed display or PLC integration

Not sure what you need? Start with your load, target speed, and travel; we’ll size the drum, groove, and drive to match.

Aluminum vs. stainless vs. coated steel — which should you choose?

| Aspect | Aluminum-Alloy Lightweight | Stainless Steel | Coated Steel |

| Weight | Lowest — easiest to move/install | Medium | Highest |

| Corrosion resistance | Good (upgradeable with SS hardware/coatings) | Excellent | Good (depends on coating) |

| Cost | Cost-effective for light duty | Higher | Moderate |

| Best for | Tight spaces, mobile rigs, light pulls | Marine/food/chemical, wash-down | General industrial, sheltered outdoor |

If you’re on the coast or in a chemical splash zone and still want light handling, consider aluminum body + stainless fasteners + coated cabinet as a hybrid.

Configuration options (mix & match)

- Rope & drum: wire/synthetic, groove profile, outlet guide, level-wind for long travel

- Control: pendant, panel with speed knob or presets, wireless, encoder counter for length/speed

- Power & drive: VFD for soft start/stop; brake options for self-holding when power is off

- Enclosure: splash-resistant cabinet, IP upgrades, heaters for low-temperature sites

- Mounting: base frame, wall/vertical brackets, vibration pads, lifting eyes

- Docs & tests: datasheet, wiring diagram, FAT, load test log, export crating

Installation & commissioning checklist

Mounting: base holes, center height, rope exit orientation confirmed

- Power: voltage/frequency, breaker size, ground/EMC practices

- Rope path: outlet guide, fairleads, sheave diameters, minimum bend radius

- Controls: pendant/wireless pairing, interlock logic, E-stop test

- Limits: set/verify upper–lower limits and overload response

- Documentation: wiring diagram, O&M manual, daily/weekly checklists

FAQ (lightweight model specifics)

Q1: Can I use synthetic rope?

Yes. We’ll adapt the groove profile and guides to your rope type and may derate the line pull slightly. Tell us rope diameter, breaking load, and environment.

Q2: Do I need a level-wind?

Not for short travel and careful operation. For longer travel or frequent cycles, a level-wind extends rope life and keeps layers uniform.

Q3: What happens on power loss?

Specify a brake if you need self-holding. With a VFD, we tune decel curves; for slopes or back-driving loads we size brake torque accordingly.

Q4: Can I read length and speed on a display?

Yes. Add an encoder with a panel meter or integrate the signals into a PLC/HMI.

Q5: Single-phase power available?

Some ratings can be adapted to single-phase with matched drives. Share your voltage and available amperage.