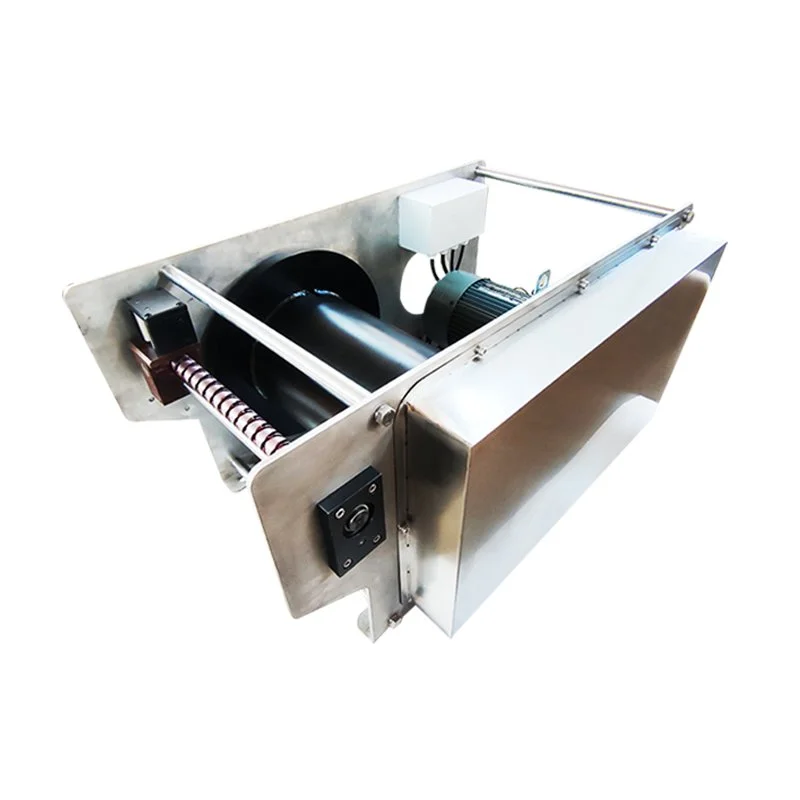

Automatic Rope-Feeding Stainless Steel Single Drum Traction Winch | Constant-Speed, Clean Layering, PLC/Encoder

Most long-travel pulling problems boil down to three risks: speed drift, messy layering, and corrosion. An automatic rope-feeding stainless steel single drum traction winch hits all three at once:

- Traction head keeps line speed constant because pulling is separated from rope storage.

- Automatic rope feed guides the rope during pay-in/pay-out so layers are tidy and repeatable—no bird-nesting.

- Stainless structure (SS304/SS316) resists salt spray, wash-down, and chemicals, making it ideal for coastal or hygiene-sensitive sites.

Problems this unit eliminates (real-world perspective)

- Speed drift over long travel → traction architecture holds a steady setpoint even as storage layers change.

- Operator babysitting → automatic rope feeding handles layering; fewer stops to fix cross-wraps.

- Corrosion and cleanup → stainless steel frame/panels, stainless fasteners and sealed components stand up to salt and detergents.

- QA visibility → add encoder feedback for length/speed readout and simple proof-of-process logs.

- Over-tension events → torque/overload limits and interlocks keep fixtures, ropes, and test pieces safe.

“Is it for us?” — three common scenarios

- Coastal pier / deck work / outdoor test rigs

You need stainless steel for longevity, but you also do long pay-in/pay-out cycles. Automatic rope feed reduces downtime and protects rope life.

- Food/chemical labs with wash-down

Stainless single-drum traction gives you smooth motion and cleanable surfaces. The auto feed ensures technicians spend time on tests, not on re-layering.

- Long positioning runs in factories

Where space is tight and cycles are frequent, constant speed + guided storage = predictable takt times and fewer resets.

What “good” looks like (spec cues pulled from typical builds)

- Traction class: light/medium traction (representative configurations include ~250 kg traction)

- Travel: long runs are expected (e.g., around 300 m total rope)

- Line speed: smooth, controlled motion (around 15 m/min is a common target for similar builds; tune via VFD/servo)

- Controls: pendant or panel as baseline; upgrade with VFD, encoder length/speed, and optional touch HMI

- Safety: E-stop chain, upper/lower limits, overload/torque limits; self-holding brake sized to back-driving torque

(Your final spec will be sized to your load, speed, duty cycle, and environment—these are cues, not limits.)

How to specify it without missing anything

- Traction force (kN or kg) and duty (cycles/hour; continuous or intermittent)

- Target line speed (m/min) and acceptable tolerance; need soft starts/stops?

- Rope: type (wire/synthetic), diameter, total travel (m); any minimum bend radius constraints

- Automatic rope feeding: required; also note if you want level-wind on the storage drum

- Power: voltage/frequency; single-phase limitations if any

- Controls: pendant/panel/wireless; encoder length/speed display; PLC/HMI integration needs

- Environment: indoor/outdoor, temperature range; SS304 or SS316 preference; cabinet IP target

- Compliance & docs: FAT, load test log, certificates; export packaging; target ship date

Cost & lead-time levers you can control

- Higher traction and duty raise motor/drive/brake sizing.

- Faster line speed and tighter tolerances call for VFD/servo and refined ramps.

- Longer travel requires drum geometry, groove pattern, and guide choices that protect the rope.

- Material & IP (SS316, sealed bearings, cabinet rating) scale with environment severity.

- Controls (encoder display, PLC/HMI, SCADA tags) add value for QA and line integration.

Micro-FAQ

- Can we run synthetic rope? Yes; we’ll match groove/guide hardware and apply sensible derating.

- What happens on power loss? Order a self-holding brake and define decel curves; the system performs a controlled stop.

- Do we need level-wind as well as auto feed? For very long storage, yes—auto feed + level-wind yields the cleanest layers.

- Can we start simple and add PLC later? Ask for reserved terminals/I/O; upgrades are straightforward.