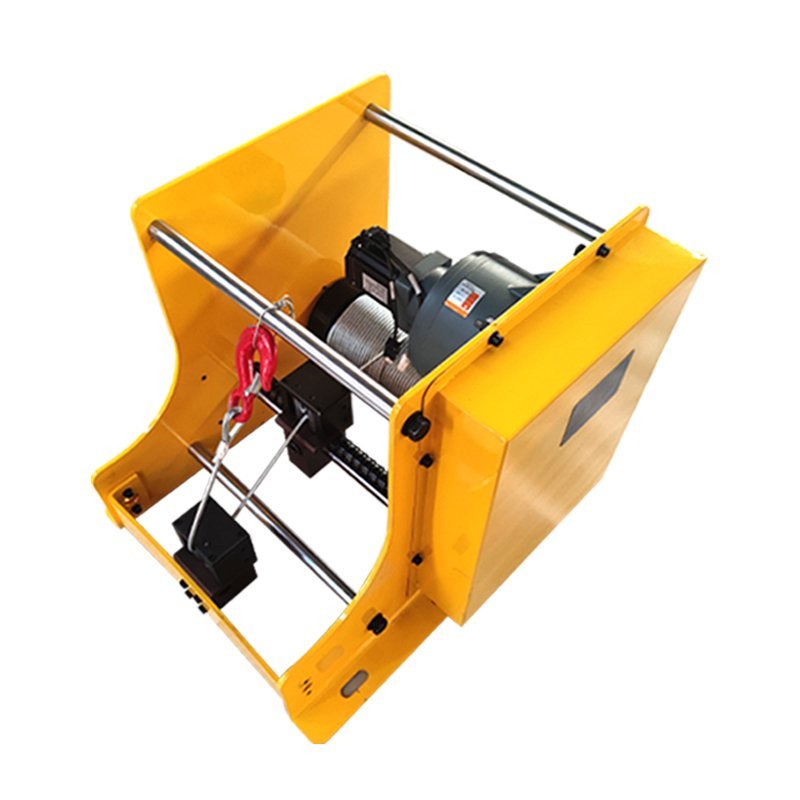

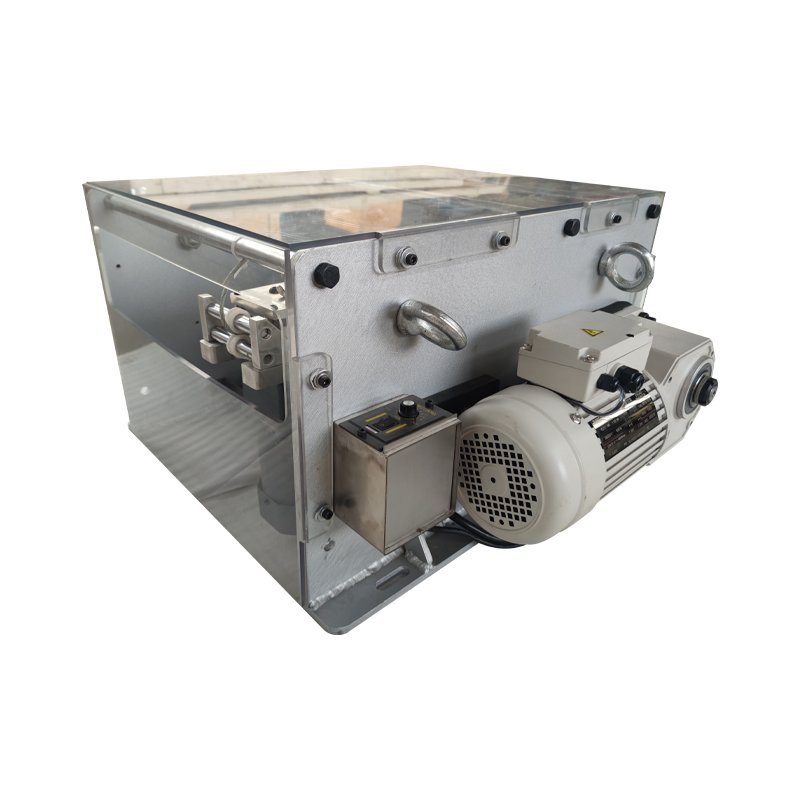

This automatic rope-feeding electric traction winch is designed for stable and continuous cable pulling in industrial applications.

With a compact structure and auto rope-feeding mechanism, it ensures smoother line handling, reduced operator intervention, and reliable traction over long pulling distances.

The winch is suitable for material pulling, equipment positioning, and system integration projects where consistent pulling force, controllable speed, and long rope length are required.

All specifications can be customized, including pulling capacity, rope diameter and length, line speed, control method, power supply, and mounting structure.

👉 Send us your application details and working parameters to get a matched configuration and factory quotation.

Linkedin

Linkedin

Google +

Google +