Comprehensive Explosion-Proof Winch Solution for Zone 2 Explosive Gas Environments in High-Temperature Oilfields

—Case Study: Iraq's EBS Oilfield

I. Application Environment

Iraq's EBS Oilfield represents a typical Middle Eastern oilfield operating condition. Field equipment is continuously exposed to a complex environment characterized by high temperatures, intense sunlight, dust, and the presence of explosive gases.

Based on actual project data, ambient temperatures can reach up to 55°C (131°F). Under intense sunlight, metal surface temperatures may further rise to 85°C (183°F). Additionally, this area is explicitly classified as an Explosive Gas Zone 2 environment.

Winch systems operating in such conditions must withstand not only mechanical loads but also thermal stresses, potential ignition risks, and prolonged outdoor aging. These operational demands dictate that:

the project cannot adopt any direct application of “standard industrial winches.”

II. Engineering Requirements

The project's core expectations for the winch extend beyond simple lifting capacity to encompass system-level safety and stability, including:

Long-term operation at 4300kg rated load and 82m lifting height

Compliance with Ex d IIB T4 explosion-proof rating and IEC 60079 standards

Maintaining uncompromised braking and control performance in high-temperature environments

Minimizing unplanned downtime risks caused by environmental factors

In essence, the project's primary concern is:

Whether the hoist remains controllable under “worst-case operating conditions.”

III. Risk Assessment

Engineering evaluations reveal that the primary risks in this scenario are not isolated but result from multiple overlapping factors:

High temperatures degrading braking and insulation performance

Explosive gases amplifying consequences of any electrical anomalies

Accelerated material degradation from outdoor sunlight and temperature fluctuations

If selection is based solely on “parameter compliance,” these risks will manifest collectively during operation.

IV. Solution

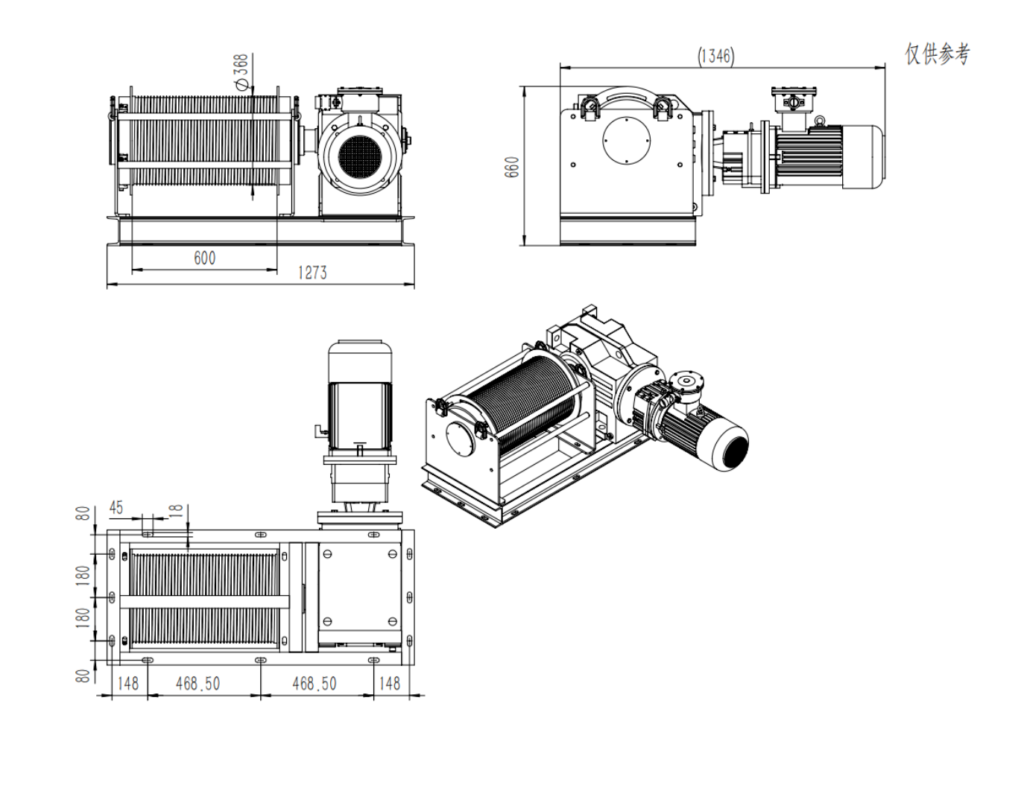

Based on this assessment, the project adopted an engineering-grade explosion-proof winch solution. This involves targeted design across five dimensions—structure, explosion protection, electrical systems, shielding, and corrosion resistance—rather than applying generic models.

V. Engineering Logic

The core logic of this solution is:

Address environmental risks proactively during the design phase, rather than leaving them to be managed during operation.

Results Validation

This solution has been successfully deployed at the EBS Oilfield project site, achieving stable operation in high-temperature explosive environments, validating the overall solution's engineering effectiveness.

FAQ

Q: When is an engineering-grade explosion-proof hoist mandatory?

A: When explosive gas zones, high temperatures, or prolonged outdoor operation are present.

Q: Why can't selection be based solely on load parameters?

A: Because environmental factors significantly reduce the actual safety margin.

Q: What is the core difference between scenario-based solutions and standard products?

A: The former starts with the environment and risk, not the parameters themselves.