Direct-Drive Industrial Winch | High-Efficiency Drive, VFD/PLC Control & Long-Stroke Customization

In day-to-day discussions with engineering customers, one pattern stands out:

whenever the working conditions call for stable pulling/lifting, precise speed control and low maintenance cost, a direct-drive industrial winch is usually the better choice.

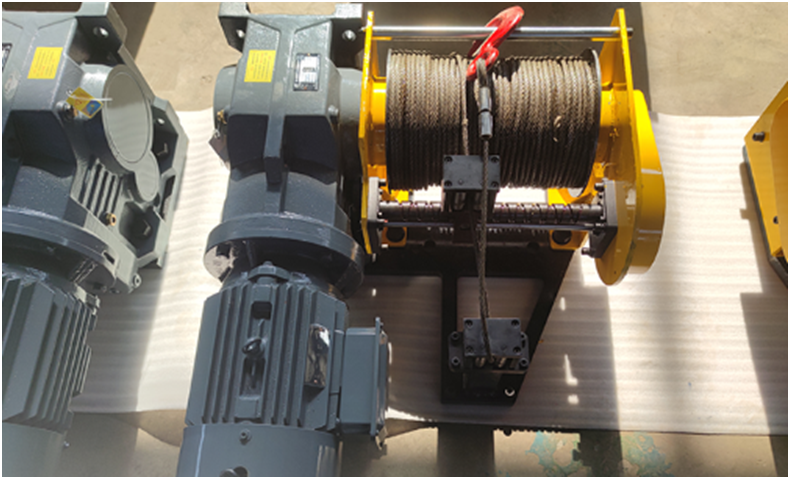

With the motor directly coupled to the gearbox, the transmission chain is shorter and mechanical efficiency is higher. Combined with VFD/PLC control and encoder feedback, the winch runs smoothly and keeps speed and position under tight control.

In one sentence, the direct-drive industrial winch is a high-efficiency hoisting/traction system for test lines, plant pulling/positioning and long-stroke reciprocating movement—delivering efficiency, smooth operation and easy maintenance in a compact footprint.

Key Advantages

High-Efficiency Direct-Drive Platform

The direct-coupled output cuts out intermediate transmission stages, lowering energy loss and improving response. Frequent starts and stops are handled more comfortably and with less stress on the drive train.

Smoother Speed, Predictable Control

Standard or optional VFD (variable frequency drive) and encoder enable soft start/soft stop, constant-speed operation, and real-time length/speed display. This is especially useful for test benches and long-stroke positioning.

Engineering-Grade Customization

Load, line speed, travel, drum diameter/width, groove pattern/level-wind, control cabinet (PLC/HMI) and material protection can all be customized project by project to match the actual site conditions.

Fewer Maintenance Points, Less Downtime

The direct-drive layout itself is low maintenance. Routine care focuses on the motor, brake and bearings, making it easy to establish a clear inspection and maintenance schedule.

Typical Applications

- Test Lines / Laboratories

Constant-speed pulling with traceable length and speed data.

Recommendation: VFD + encoder + HMI, with PLC/SCADA I/O reserved for system integration. - Plant Material Pulling / Jig & Fixture Positioning

Cycle-based start/stop for production takt.

Recommendation: direct drive + brake, multi-step speeds and integrated emergency stop/limit chains. - Long-Stroke Reciprocating / Positioning

Drums and grooves are designed according to rope diameter and travel. Guide rollers or level-wind devices can be added where needed to protect layering quality and rope life. - Outdoor / Corrosive Environments

Optional stainless-steel components, sealed bearings and appropriately rated IP electrical enclosures improve weather resistance and cleanability.

Example Specification Range

(Custom designs available)

- Rated pulling / lifting capacity:

From light duty up to multi-ton ranges (calculated based on your working conditions). - Line speed:

Typically 6–20 m/min, adjustable up or down, with configurable acceleration and deceleration curves. - Total travel / rope capacity:

From tens to several hundred meters; multi-layer spooling with level-wind/guide options. - Rope type:

Wire rope or synthetic rope, with drum and outlet designed to respect minimum bending radius and wear requirements. - Power supply:

Three-phase 380–480 V, 50–60 Hz; single-phase schemes can be evaluated for special cases. - Control:

Pendant, panel or wireless remote; encoder length/speed display; PLC/HMI and upper-level system communication. - Braking & safety:

Electromagnetic or fail-safe brakes, travel limits, emergency stop chain, overload/overcurrent protection.

If your process is mainly constant-speed pulling with very long rope travel, a combined “traction head + storage winch” configuration can be used:

the traction unit guarantees constant speed, while the storage unit manages layering and capacity—often giving better overall cost and stability.

Comparison with Other Solutions

| Key Concern | Direct-Drive Industrial Winch | Friction-Type Traction Winch | High-Speed Traction Solution |

|---|---|---|---|

| Speed stability | High (easy closed-loop with VFD/encoder) | Very high (traction and storage are decoupled) | High (requires careful guidance and monitoring) |

| Efficiency & maintenance | Excellent (short transmission chain) | Medium | Medium to high |

| Long-stroke suitability | Good (with level-wind/guide options) | Strong (natural advantage for long distances) | Strong (for higher line speeds) |

| Typical applications | Plant pulling, test lines, positioning | Municipal/bridge/long-distance traction | High-speed tests and traction |

Factors That Influence Pricing

- Load and duty cycle

Determine motor, gearbox and brake size as well as thermal capacity. - Target line speed and accel/decel curve

Affect the drive selection and closed-loop control strategy. - Travel and rope path

Drive drum size, groove pattern, and whether level-wind/guide devices are required. - Environment and protection

Indoor/outdoor, temperature range, dust/moisture levels, materials (carbon steel/stainless steel), and electrical cabinet IP rating. - Control and integration

Whether the system needs PLC/HMI/SCADA integration, and whether length/speed display and data logging are required. - Compliance and testing

FAT, load test reports, third-party witnessing, documentation pack and packaging method.

RFQ Checklist

When you send an inquiry, including the following will help us respond with a clear specification and quote:

- Rated pulling/lifting load (kN/ton) and duty cycle

- Target line speed (m/min) and allowable variation; need for soft start/soft stop

- Total travel (m), rope diameter/type; requirement for level-wind/guide/rope outlet protection

- Power supply (voltage/frequency); any single-phase or power-limit constraints

- Control mode (pendant/panel/wireless), need for encoder length/speed display, and PLC/HMI/SCADA integration

- Safety chain (emergency stop, limits, overload) and documentation needs (FAT, certificates, O&M manuals)

- Installation space and rope direction, requirement for base/frame/guards

- Operating environment (indoor/outdoor, temperature and humidity, corrosion/cleaning frequency), material choices and target IP level for the electrical cabinet

- Target delivery time and logistics (sea freight/air freight)

Based on this information, we can prepare a dedicated specification sheet, detailed quotation and production schedule, together with rope-path and installation recommendations to help you achieve trouble-free commissioning and long-term stable operation.

Frequently Asked Questions

Q1: Why is a direct-drive winch easier to live with?

Because the transmission chain is short, mechanical efficiency is high and there are fewer maintenance points. Control over frequent start/stop cycles and constant-speed running is also better.

Q2: Can length and speed be displayed in real time and logged?

Yes. An encoder can be installed and connected to a panel or HMI for display, with I/O reserved for upper-level systems or data acquisition.

Q3: Will long travel cause messy rope layering?

Drum and groove design are matched to rope diameter and travel. Where needed, a level-wind/guide or a traction + storage winch combination can be used to significantly improve layering and rope life.

Q4: How do you handle outdoor or corrosive environments?

Options include stainless-steel components, enhanced anti-corrosion coatings, sealed bearings and electrical cabinets with appropriate IP ratings, plus low- or high-temperature solutions as required.