Double Drum Electric Winch 3000kg | Synchronous Wire Rope Winch for Industrial Automation | KLD

I. Product Overview

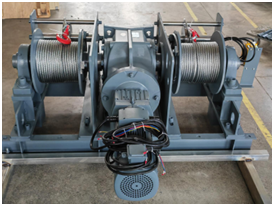

Double Drum Industrial Electric Winch is a professional industrial device designed for applications requiring synchronous retraction and release of double ropes. It utilizes a single-motor reduction synchronous drive structure, ensuring consistent output for both wire ropes from the power source. This effectively avoids common issues found in traditional dual-motor solutions, such as uneven tension, synchronization errors, and complex maintenance.

This equipment is widely applicable to scenarios demanding high stability and synchronization, such as military and special vehicle outfitting, industrial automation recovery systems, and engineering equipment integration. It supports multi-parameter customization and is suitable for long-term stable operation as a system-level device.

II. Engineering Application Experience

In actual engineering projects, double-rope operation systems often face the following pain points:

- Dual-motor drive synchronization is difficult: Long-term operation easily leads to tension deviation.

- Rope management issues: Rope piling and tangling often occur during recovery, leading to high maintenance frequency.

- Complex control system: Multiple failure points reduce engineering reliability.

In relevant engineering projects, this Double Drum Industrial Winch has been used for dual-cable synchronous recovery and traction systems. Through the single-motor reduction synchronous drive method, it maintains consistency in double-rope operation even under long rope lengths and continuous working conditions. This significantly reduces system adjustment and maintenance costs caused by desynchronization and enhances overall equipment reliability.

III. Core Design and Technical Advantages

1. Single Motor Synchronous Drive Structure A single gear motor drives both drums simultaneously, achieving synchronization at the mechanical structural level. This avoids inconsistent tension caused by motor response differences or electronic control deviations, making it more suitable for industrial applications requiring synchronization precision and long-term stability.

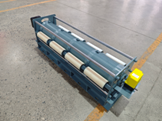

2. Grooved Drum + Rope Arranger (Double Spooling Design) The drum surface features a grooved structure combined with a rope arranging wheel (guide) design. This ensures the wire rope is arranged orderly layer by layer during retraction and release, effectively reducing tangled ropes and piling, extending the service life of the wire rope, and lowering daily maintenance pressure.

3. Mechanical Limit Protection The equipment is equipped with mechanical upper and lower limit devices. These can be flexibly adjusted according to actual stroke requirements to effectively control the winch's working range, preventing over-winding or over-travel, and enhancing system operational safety.

4. Compact Structure, Easy System Integration The overall layout is rational and compact, occupying minimal space. It is easy to install inside various industrial equipment or systems, making it suitable for project-based equipment integration and non-standard custom applications.

IV. Key Parameters Example

The following are typical configuration parameters. Actual specifications can be customized according to working conditions:

- Model: 3000 KG

- Rated Pull: 3000 kg

- Wire Rope Diameter: 12 mm

- Rope Length: 50 m

- Motor Power: 3 kW

- Drum Speed: 4.8 rpm

- Average Rope Speed: 307 m/min (Note: This value in the source text seems unusually high for the given RPM/Power, possibly a typo for 3-7 m/min or similar, translated as written)

- Power Specification: 220V / 60HZ / Single Phase

Note: The above parameters are based on rated working conditions. Custom design is supported for pull force, rope length, speed, voltage, and control methods.

V. Applicable Scenarios and Selection Suggestions

This Double Drum Industrial Electric Winch is particularly suitable for the following scenarios:

- Recovery or traction systems requiring strict synchronous operation of double ropes.

- Industrial equipment where operational stability is prioritized over speed.

- Engineering projects looking to simplify control systems and reduce failure rates.

- Equipment integrators requiring non-standard parameter customization based on actual working conditions.

If your application scenario has clear requirements for synchronization accuracy, reliability, and long-term operational stability, this equipment is a mature and reliable solution for selection.

VI. Customization and Service

This product supports customization according to project requirements, including but not limited to:

- Pull force rating and rope length configuration.

- Power specifications (Single-phase / Three-phase).

- Control methods and interface forms.

- Installation structure and system integration schemes.

We can cooperate with complete machine equipment or system schemes for in-depth design to meet the actual usage needs of different industrial scenarios.

Double Drum Industrial Winch FAQ

Q1: What is a Double Drum Industrial Winch? How is it different from a standard winch? A Double Drum Industrial Winch is an industrial lifting and traction device that drives two drums simultaneously to achieve synchronous retraction and release of double ropes. Compared to a single-drum winch, its core advantages are:

- Simultaneous control of two wire ropes.

- Suitable for applications requiring dual-point loading or symmetrical loading.

- Effectively improves system stability and safety. In industrial applications requiring double-rope synchronization, stable posture, or load balancing, the double-drum structure offers better engineering adaptability.

Q2: Why is the single-motor synchronous drive recommended for Double Drum Industrial Winches? In engineering practice, single-motor synchronous drive has higher reliability compared to dual-motor schemes:

- Output from the same power source ensures natural synchronization.

- Avoids uneven tension caused by differences in dual-motor response.

- Simpler control system with fewer failure points. Therefore, for projects requiring long-term stable operation and synchronization accuracy, single-motor driving double drums is a more mature and reliable choice.

Q3: Which typical industries or scenarios are Double Drum Industrial Winches suitable for? This type of equipment is widely used in:

- Military and special vehicle dual-cable recovery systems.

- Double-rope traction or lifting in industrial automation equipment.

- Symmetrical loading systems for engineering equipment.

- Customized mechanical devices requiring dual-point synchronous movement. Any working condition with requirements for double-rope synchronization, force balance, or posture control is suitable for selecting a Double Drum Industrial Winch.

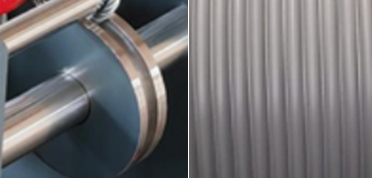

Q4: How does the Double Drum Winch ensure the wire rope does not tangle or pile up? Industrial-grade double drum winches typically use:

- Grooved Drum Structure: Guides the wire rope to arrange by layer.

- Rope Arranger (Guide) Design: Limits lateral deviation of the rope. The dual spooling design effectively reduces tangled ropes, track jumping, and piling problems, extending wire rope life while reducing maintenance frequency.

Q5: How is the synchronization accuracy of the Double Drum Industrial Winch guaranteed? Synchronization accuracy is mainly determined by:

- Single-motor reduction synchronous drive structure.

- Machining precision of drum diameter and rope grooves.

- Overall rigidity and assembly precision of the mechanical structure. By relying on mechanical synchronization rather than complex electronic control synchronization, stable and repeatable double-rope synchronization effects can be achieved in most industrial applications.

Q6: Does the Double Drum Industrial Winch support customization? Yes, Double Drum Industrial Winches are typically engineering-customized equipment. Parameters can be configured according to project needs, including:

- Rated pull and rope length.

- Wire rope diameter.

- Power specifications (Single-phase / Three-phase).

- Running speed and control method.

- Installation structure and interface forms. Customization capability is a key reason why this type of equipment is suitable for complex industrial scenarios.

Q7: What is the function of the mechanical limit switch in the Double Drum Winch? The mechanical limit device is used to limit the maximum retraction and release stroke of the winch. Its main functions include:

- Preventing over-winding and over-releasing.

- Avoiding wire rope derailment or impact on the structure.

- Improving system operational safety. In industrial applications, mechanical limits serve as a basic safety protection measure, offering high reliability and intuitive structure.

Q8: Is the maintenance cost of the Double Drum Industrial Winch high? Compared to dual-motor schemes, the single-motor synchronous drive Double Drum Winch has:

- Simpler structure.

- More stable control system.

- Fewer maintenance points. Under normal working conditions, maintenance mainly focuses on the wire rope, bearings, and limit devices. The overall maintenance cost is controllable, making it suitable for long-term operation projects.

Q9: Can the Double Drum Industrial Winch work continuously? Whether it supports continuous work depends on:

- Motor power and duty cycle rating (Work duty).

- Actual load ratio.

- Working environment and heat dissipation conditions. With reasonable selection and matching of working conditions, the Double Drum Industrial Winch can meet industrial continuous or high-frequency operation requirements.

Q10: What are the most easily overlooked issues when selecting a Double Drum Industrial Winch? Key points often ignored in engineering selection include:

- Is "absolute synchronization" of the double ropes strictly necessary?

- The impact of rope length changes on synchronization.

- Matching of installation space with the load-bearing structure.

- Convenience of later maintenance and overhaul. Fully considering these issues during the selection phase can effectively avoid later rework or system instability risks.

Q11: Is a Double Drum Industrial Winch the same as a Double Drum Hoist/Windlass? In the industrial field, "Winch" (卷扬机) and "Hoist/Windlass" (绞车) are often used interchangeably and usually refer to similar equipment. The key lies not in the name, but in whether its structural form, drive method, and application conditions meet actual needs.

Q12: When is it NOT recommended to use a Double Drum Industrial Winch? The double drum structure is not the optimal choice in the following scenarios:

- Only single-rope operation is needed.

- Synchronization requirements are not high.

- Projects where space is extremely limited and costs are sensitive. Rational selection is more important than simply pursuing structural complexity.