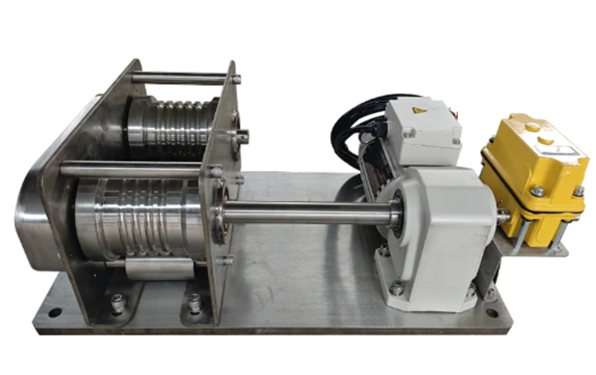

Electromagnetic Clutch Type I Winch – Factory Direct | Custom Design, Quotation & Lead Time Evaluation

If your line needs fast inching, long-stroke reciprocation, neat multi-layer spooling and seamless connection to PLC/HMI/encoders, this Electromagnetic Clutch Type I Winch is built for that job.

Key Advantages

Fast inching response

The electromagnetic clutch allows instant engage/disengage of torque, which is much better than relying on the brake alone for fine positioning, short indexing and high-frequency start/stop.

Flexible rope options

The winch can be matched with different rope types for different environments, covering a wide range of customer requirements.

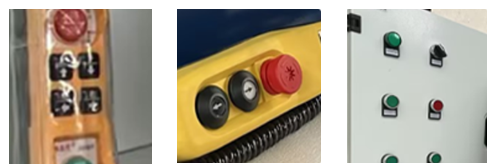

Multiple control modes

Available with pendant control, panel control and wireless remote control for easy operation and supervision on site.

High degree of customization

Payout direction, spooling method and rope exit direction can all be customized. The package is designed around your actual working conditions instead of a fixed standard model.

Typical Specification Range

- Pulling / lifting capacity

From light duty up to multi-ton class, designed by kN/ton and duty cycle. - Line speed

Around 6–20 m/min as a typical range. Can be increased or decreased according to the application and matched with soft start/soft stop curves. - Total travel

From a few tens of meters up to several hundred meters. Drum diameter/length, groove pattern and spooling system are matched to rope diameter and travel distance. - Rope type

Common steel wire ropes in the Ø8–Ø16 mm range. Synthetic rope is also possible with proper de-rating and anti-wear treatment at the outlet. - Power supply

3-phase 380/400/480 V, 50/60 Hz. - Control & indication

Pendant / panel / wireless control; encoder-based length and speed display; PLC/HMI recipes, logs and I/O interlocks can be integrated as needed. - Safety functions

Electromagnetic / fail-safe brake, upper and lower limit switches, emergency stop, overload/overcurrent/overtemperature protection. Audible and visual alarms and access interlocks can be added.

Typical Applications

- Fixture / tooling positioning

Frequent inching, stable cycle time, low impact. Suitable for precise fixture alignment and tooling movement. - Test and durability rigs

Constant-speed segments with length/speed recording for QA, repeatability and traceability of test conditions. - Long-travel positioning

60–300 m reciprocating movement while keeping rope layers neat and controlled, reducing wear. - Outdoor / near-shore / clean environments

Stainless steel components, sealed bearings and suitable IP-rated electrical cabinets for corrosion resistance and washdown-friendly setups.

Why Engineering Buyers Like This Solution

- Direct link to manufacturer / supplier

Factory engineers participate in model selection and drawing review, which cuts down back-and-forth communication and technical uncertainty. - OEM / ODM friendly

Load × speed × travel × rope diameter × control philosophy × material / IP rating can be combined as required instead of forcing your project into a standard catalog size. - Transparent pricing

Quotations are broken down based on “load / speed / travel / control / environment / documentation”, making it clear what you are paying for. - Controllable lead time

You receive a production schedule plus FAT (Factory Acceptance Test) plan, so delivery milestones are clear from the beginning.

What Drives Price and Lead Time?

- Pulling capacity & duty cycle

Motor, gearbox and brake sizing plus thermal balance are determined by the load and duty. - Line speed & control curve

VFD parameters and clutch logic (soft start/stop, emergency stop strategy) affect the drive package and commissioning. - Travel length & rope path

Drum geometry, groove pattern, guide/level-wind design and minimum bending radius are all linked to travel and rope routing. - Control & system integration

Choice of pendant/panel/wireless control, encoder display, PLC/HMI integration and I/O or communication interface definition. - Environment & materials

Stainless steel proportion, electrical cabinet IP rating, low-temperature heaters/dehumidifiers, salt-spray conditions and cleaning frequency. - Compliance & documentation

FAT requirements, load tests, certificates/nameplates, export packaging and transportation method.

Quick Comparison

Electromagnetic Clutch Type I Winch vs. Brake-Only / General-Purpose Winch

| Focus Point | Electromagnetic Clutch Type I Winch | Brake-Only / General-Purpose Winch |

|---|---|---|

| Inching / indexing | Strong advantage (fast response, low drag) | Oriented to “holding”; inching is less precise |

| Long-travel spooling | More stable with matched level-wind / guides | Often requires extra spooling design |

| System integration | VFD + PLC/HMI + encoder designed as one package | Control stack often needs later upgrades or add-ons |

| Installation / upgrade | Easy to install, with clear upgrade path | Retrofit costs and downtime can be higher |

Quotation Checklist

To prepare a detailed specification, quotation and production plan, please provide:

- Rated pull (kN/ton) and duty cycle

S-class or expected starts per hour. - Target line speed (m/min) and tolerance

Do you need soft start/soft stop? - Total travel (m)

Rope diameter/type; need for level-wind; rope direction and routing. - Clutch / brake configuration

Clutch and brake together? Emergency stopping strategy? - Power supply

380/400/480 V, 50/60 Hz, plus any on-site constraints. - Controls

Pendant / panel / wireless; need encoder length/speed display and PLC/HMI integration or not. - Environment

Indoor / outdoor / near-shore, washing frequency, temperature range; target IP rating of electrical cabinet. - Documentation & delivery

FAT, load test requirements, certificates, packing standards and target delivery date.

Once we receive this information, we will return a dedicated datasheet, itemized quotation and production schedule, together with rope path and installation recommendations to help you install once and run stably for the long term.

FAQ

Q: Can we start with simple pendant control and connect to PLC/HMI later?

Yes. The electrical design reserves I/O and communication points, so upgrading to PLC/HMI control does not require major rewiring.

Q: Will high-frequency inching cause overheating?

We calculate thermal balance according to your cycle. If necessary, we add cooling, derating curves or cabinet air channels to ensure continuous operation.

Q: Is level-wind mandatory for long travel?

For travel ≤20–30 m and disciplined operation, guide rollers may be enough. For longer travel or high-cycle use, we recommend level-wind for more stable layering and longer rope life.

Q: Can synthetic rope replace steel wire rope?

Yes, provided the drum groove and guides are matched and reasonable de-rating is applied. We also recommend anti-wear protection at the outlet and larger sheave radii.

Q: Will the load run away in case of power failure?

A fail-safe brake is included and the system is designed for controlled deceleration. For back-driving loads, we calculate the required braking torque and provide redundancy in the braking solution.