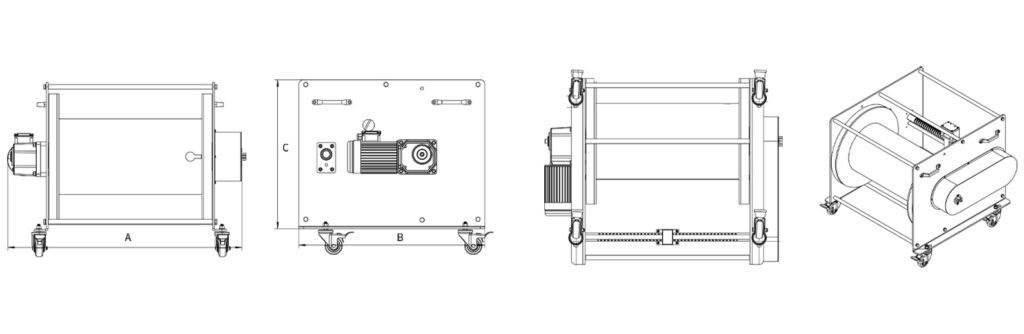

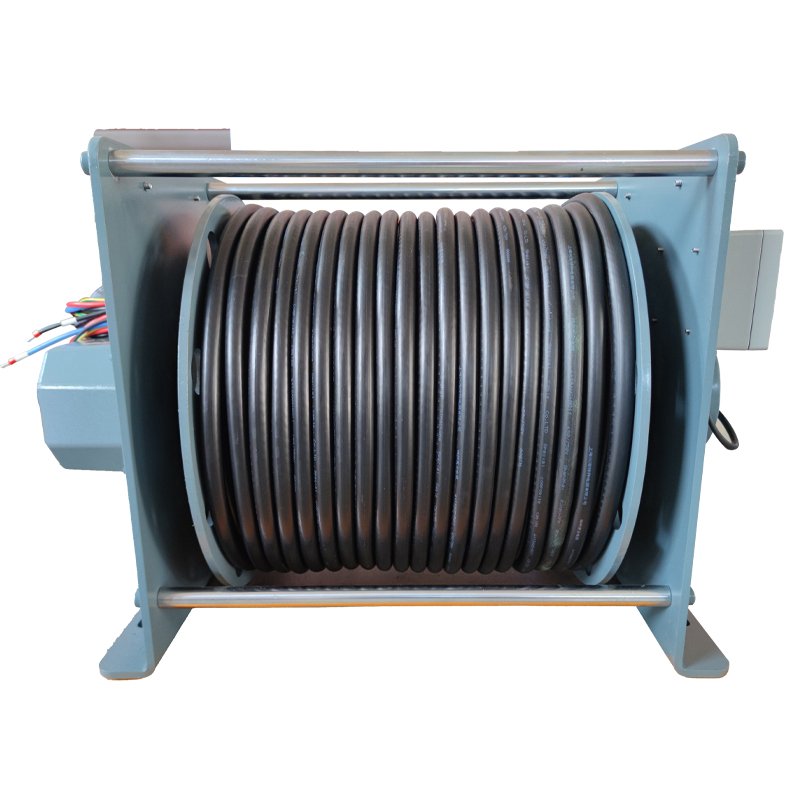

This traction winch is specially designed for winding fiber optic cables, capable of providing power support while transmitting signals. The equipment is equipped with a large-capacity drum; in this case, it can accommodate cables up to 300 meters in length and 15mm in diameter, making it suitable for operations requiring large-capacity cabling. The product supports customization, with parameter configurations adjustable according to specific requirements.

Design advantages:

-

Supports fiber optic cable winding, integrating both signal transmission and power supply functions.

-

Large-capacity drum design can hold up to 300 meters of cable, greatly improving work efficiency.

-

Equipped with a reciprocating screw rope guider to ensure neat and orderly cable arrangement, preventing tangling.

-

Powered by 220V, compatible with standard household power supply, convenient to use without additional power requirements.

-

Fitted with a slip ring relay to ensure stable transmission of both signal and power, enhancing reliability.

-

Universal wheels at the base allow easy movement by a single operator, providing flexible and effortless mobility.

Linkedin

Linkedin

Google +

Google +