In many engineering projects and non-standard automation systems, winches are often treated as a “small accessory”:

As long as it can lift or pull the load, a standard construction winch is selected in a hurry.

However, once the equipment is put into real operation, problems quickly emerge:

- When lifting frequency increases slightly, the motor and gearbox overheat, and service life drops sharply;

- Braking performance is unstable, with occasional load slipping, creating serious safety risks;

- In the event of power failure or control system malfunction, loads remain suspended mid-air, operators hesitate to intervene, and production lines are forced to stop.

In such scenarios, an I-type single-column industrial winch is a far more suitable choice.

For example, the KLD I-shaped Industrial Winch is specifically designed for continuous industrial duty and equipment integration applications.

1. What Is an I-Type Single-Column Industrial Winch?

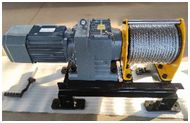

The term “I-type” primarily refers to the structural design.

The winch adopts a single-column / single-side support structure, where the motor, gearbox, and drum are arranged along the same axis, forming a compact “I-shaped” profile.

This configuration is especially suitable for installation on equipment frames, steel columns, or platform sides, as it requires minimal floor space.

Taking a typical KLD I-type industrial winch as an example:

- Rated lifting / pulling capacity: 2000 kg

- Motor power: 4 kW

- Drum output speed: approx. 5.7–6.4 m/min

- Wire rope diameter: 13 mm

- Wire rope capacity: approx. 23 m

- Self weight: approx. 240 kg

For many small- to mid-capacity equipment systems, this configuration offers an excellent balance between pulling force, operating speed, and compact size.

2. Why Choose an M5 Duty Industrial Winch for High-Frequency Operation?

Small construction winches are typically designed for short-term, intermittent operation.

In factories and integrated equipment systems, however, winches often run through multiple cycles per day, sometimes approaching near-continuous operation.

The KLD I-type industrial winch can be designed up to M5 duty class, making it suitable for:

- Frequent lifting or pulling stations on automated production lines;

- Material handling and flipping mechanisms requiring long operating hours;

- Applications demanding high safety margins and minimal downtime.

In addition, the overall noise level is relatively low, making it suitable for installation inside workshops, laboratories, and production halls—without the excessive noise commonly associated with construction winches.

3. What Happens During a Power Failure?

The Value of Manual Emergency Operation

When selecting a winch, many engineers focus only on load capacity and price, overlooking a critical question:

What happens if the winch loses power while lifting a full load?

For most low-cost winches, the answer is simple:

- Wait for power restoration; or

- Ask operators to handle the situation manually, often involving safety risks and unpredictable losses.

The I-type industrial winch offers a clear upgrade in this area:

- A manual emergency hand crank is installed at the motor tail.

- In case of power outage, motor failure, or control system issues, operators can manually and gradually release the load, allowing it to descend safely.

Additionally, manual operation can be used for fine positioning, which is particularly useful in tooling systems requiring precise alignment.

For automated production lines, test platforms, and personnel-related applications, this controlled emergency solution provides far greater safety value than braking systems alone.

4. Electromagnetic Brake + R-Series Gear Motor

A Balance of Efficiency and Safety

This type of I-shaped industrial winch uses an R-series coaxial helical gear reducer motor, known for high transmission efficiency, compact structure, and long service life.

The system is equipped with an electromagnetic brake, ensuring fast and reliable braking response.

This combination delivers several practical advantages:

- Crisp start and stop performance

The electromagnetic brake minimizes stopping distance and prevents load slipping during shutdown. - Stable load holding

When loads need to be held at a fixed height for subsequent processes, the brake ensures reliable position locking. - Compact integration

The integrated design of gearbox, brake, and drum simplifies installation within equipment frames, making it especially OEM-friendly.

5. Typical Applications

Where I-Type Industrial Winches Excel

Based on extensive project experience, I-type single-column industrial winches are particularly suitable for:

Non-standard automation equipment

- Flipping fixtures and lifting tooling systems

- Material lifting and transfer between production line sections

- Automatic doors, platforms, and tensioning mechanisms

Chemical, metallurgical, and mining plant equipment

- Small hopper lifting systems

- Valve and gate opening/closing mechanisms

- Pipeline and maintenance platform lifting systems

Warehouse and internal logistics

- Simple lifting tables and dock leveler traction

- Rail-guided trolley pulling and positioning

Noise-sensitive environments

- Laboratory equipment

- Educational and testing apparatus

If your project falls into one of these categories, an I-type industrial winch is often a better and more approval-friendly solution than traditional construction winches or manual hoists.

6. Project-Based Customization

The example configuration above (2-ton capacity, 4 kW motor, 23 m rope, 13 mm diameter) represents only a typical setup.

In practice, KLD can customize the winch based on project requirements, including:

- Rated load: from several hundred kilograms to multiple tons

- Speed & duty cycle: lifting speed, start-stop frequency, duty class

- Wire rope specifications: diameter and length based on layout and process needs

- Control methods: local push-button, remote control, PLC integration, interlock systems

- Installation structure: column-mounted, wall-mounted, platform-mounted

- Protection levels: indoor/outdoor use, dustproof and waterproof ratings

For engineers, a winch that precisely matches operating conditions is far more valuable than a generic model—offering higher safety, longer service life, and lower maintenance costs.

7. How to Quickly Get an I-Type Industrial Winch Solution

If you are starting a new project or planning to replace an existing winch, prepare the following information for KLD engineers:

- Maximum lifting / pulling load and required safety factor

- Operating speed and estimated daily cycles or working hours

- Wire rope routing, rope exit direction, and available installation space

- Installation environment (indoor/outdoor, dust, corrosive gases, etc.)

- Control method (push-button, remote, PLC linkage, etc.)

Based on this information, our engineers will recommend a suitable I-type industrial winch model and provide a preliminary technical solution and quotation—saving you the time of comparing multiple models on your own.

Summary

For applications involving frequent lifting, high safety requirements, compact installation, and equipment integration, the I-type single-column industrial winch is a highly recommended solution.

If you are selecting equipment for a new project or replacing an unreliable temporary winch, consider upgrading to an I-type industrial winch for a more professional, durable, and long-term solution.