How to Select the Power Unit for Cement Lining Segment Shuttle Vehicles in Shield Construction?

— Evaluating Winch Solutions from Engineering Safety and System Stability Perspectives

Project Context

In shield tunnel construction, the transportation of cement lining segments is often regarded as a “supporting process.” However, in actual project operations, it directly impacts:

·Continuity of shield tunneling cycles

·Long-term stable supply at assembly stations

·Safety risk boundaries at construction sites

Reciprocating transport vehicles for concrete segments typically operate in narrow tunnels under heavy loads, frequent starts/stops, and bidirectional switching. In such environments, a power unit failure leaves virtually no room for recovery.

Engineering Challenges

Reviews of multiple shield projects reveal that issues with segment transport systems are highly concentrated in the following areas:

1️⃣ Braking Risks Under Heavy-Load Reciprocating Operation

· Risk of rollback during return trips or on inclines

· Lack of backup measures when single braking system fails

2️⃣ Uncontrollable Wire Rope Stress During Towing

· Significant start-stop impact forces

· Tension fluctuations accelerating wire rope fatigue

· Prone to rope tangling and entanglement after prolonged operation

3️⃣ Tunnel environment challenges equipment stability

· High humidity, dust, and slurry ingress

· Limited maintenance access, high downtime costs These issues stem not from “improper operation” but from inherent weaknesses in the power system design phase.

Engineering Approach

In practice, an increasing number of projects are adopting winches as the core power unit for cement pipe segment shuttle vehicles. This choice is not based on “equipment familiarity,” but on the following engineering rationale: under conditions where loss of control is unacceptable, priority should be given to power systems with “predictable failure modes and redundant braking.” The structural characteristics of winches make them better suited to shield construction requirements in the following aspects:

· Calculable and verifiable traction force

· Braking system capable of mechanical + electrical dual redundancy

· Clear wire rope path with defined force distribution

System Solution

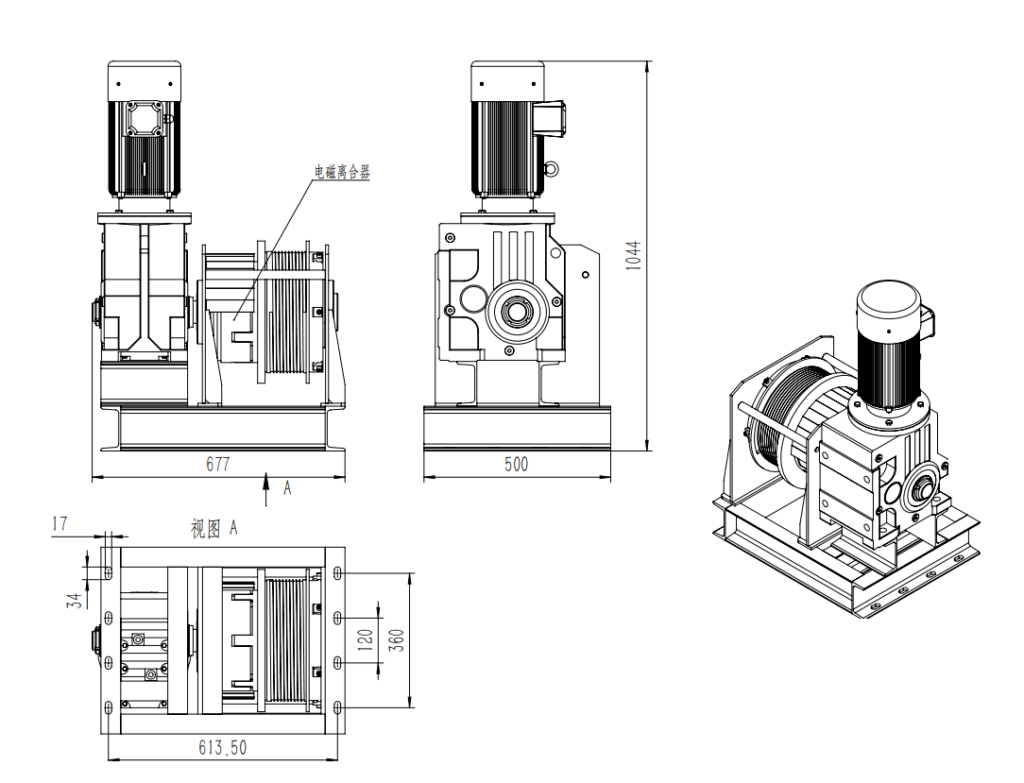

Fundamental Logic of Combined Horizontal Traction Winches

The mature engineering solution employs a combined horizontal traction system rather than a single unit:

· One winch actively retrieves rope

· Another winch pass rope under controlled conditions

· Stable shuttle car reciprocation achieved through control logic switching This configuration has one core objective: maintaining wire rope tension within safe limits during any direction of operation.

Key Engineering Design Considerations

· Low-speed, high-torque design: prioritizing stability over speed

· Forced rope-laying mechanism: preventing rope stacking and groove jumping

· Dual-brake configuration: Immediate braking upon power loss to prevent runaway

· Limit switches and interlocks: Forming a safety closed-loop with the transport system

Safety & Parameter Logic

⚠️ The following parameters are engineering examples only. Final values shall be based on actual operating conditions, slope gradients, and segment weight calculations.

| Key Parameter | Engineering Significance |

|---|---|

| Rated Traction Force | ≥ Actual Load × Safety Factor |

| Wire Rope Specification | Meets tensile strength and fatigue resistance requirements |

| Operating Speed | Aligned with construction cycle timing |

| Braking System | Service Brake + Power-Off Brake |

| Protection Rating | Suitable for tunnel environment (IP55+) |

| These parameters are not "bigger is better" but are matched through risk-based design. |

Parameters are illustrative only. Final specifications shall be determined by application context and actual requirements.

Engineering Outcomes

In practical shield construction applications, this winch solution delivers direct improvements including:

· More stable segment transport cycles

· Significant reduction in unplanned downtime

· Markedly diminished operator concerns regarding runaway or loss of control

· Predictable and manageable wire rope replacement cycles Engineering benefits manifest not in individual equipment but in the overall safety redundancy of the construction system.

Engineering Decision Recommendations

The winch solution should be prioritized in decision-making under the following conditions:

· ✔ Large segment weights and high transport frequency

· ✔ Tunnels with gradients or return-trip braking risks

·✔ Zero-tolerance policy for safety incidents

·✔ Requirement for interlocking with the shield machine's main control system This is not the lowest-cost solution, but it is often the solution with the lowest engineering risk.

Conclusion

In shield construction, true safety relies not on experience but on preemptively limiting risk boundaries through systematic design. The selection of the power unit for cement segment shuttle vehicles is fundamentally an engineering safety decision, not merely a matter of equipment procurement.

FAQ|Common Questions on Shield Segment Transport Winches

Q1: Why not use direct drive with standard motors or gearboxes?

A: Direct drive lacks sufficient braking redundancy, posing loss-of-control risks during return trips.

Q2: Can parameters be modified based on our experimental design?

A: Yes, we support customization at the parameter, control, and structural levels.

Q3: How does passive rope release prevent tangling?

A: Through controlled tension design.

Q4: Is it suitable for long-term continuous operation?

A: Yes, the solution is specifically designed for high-frequency, continuous operation.

Q5: Can parameters be modified according to our experimental requirements?

A: Yes, we support customization at the parameter level, control level, and structural level.