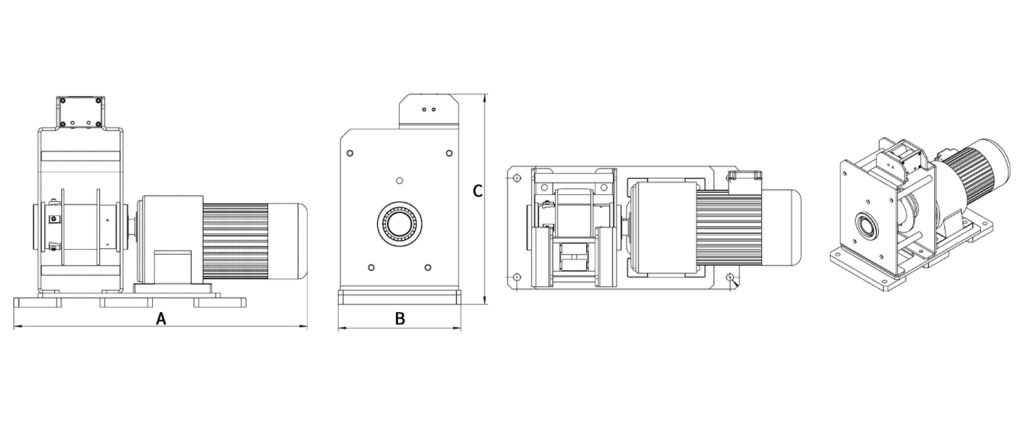

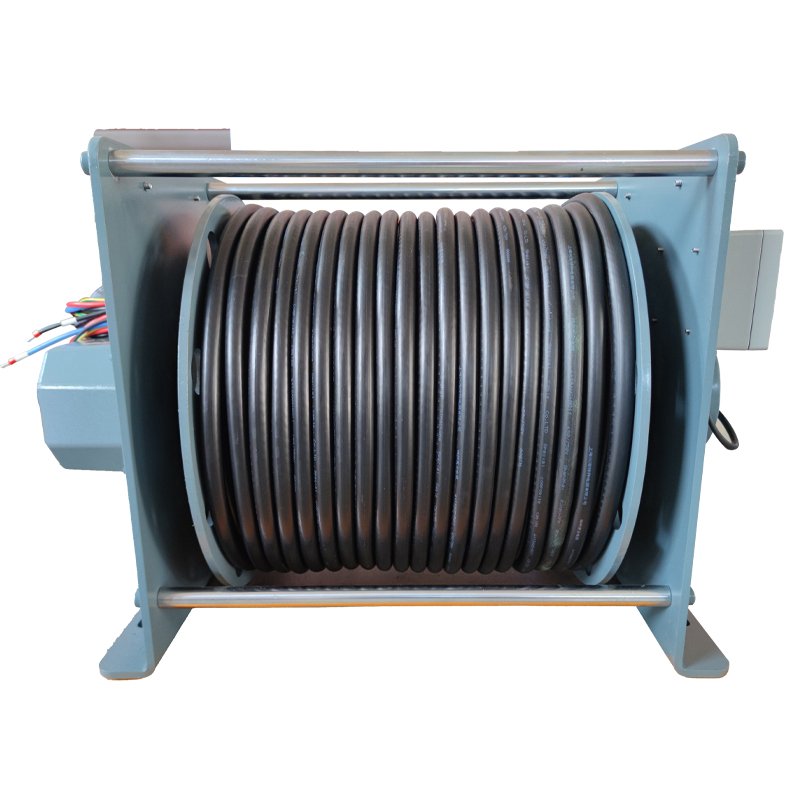

The inline industrial winch is a professional device that combines quiet operation, high efficiency, energy savings, and a compact structure. Built with a long service life, it is suitable for a wide range of traction and lifting applications. The product can be flexibly customized in terms of rated load, rope length, and rope speed to meet specific needs. Additionally, users can select enhanced protection, durability, and safety configurations based on their operating environment to ensure reliable performance in demanding conditions.

Design advantages:

-

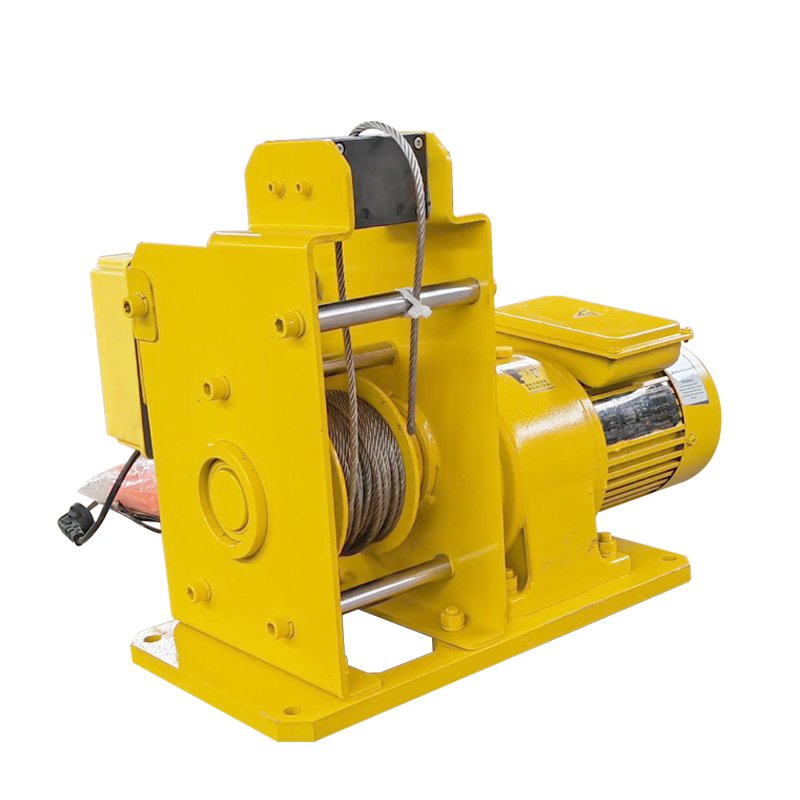

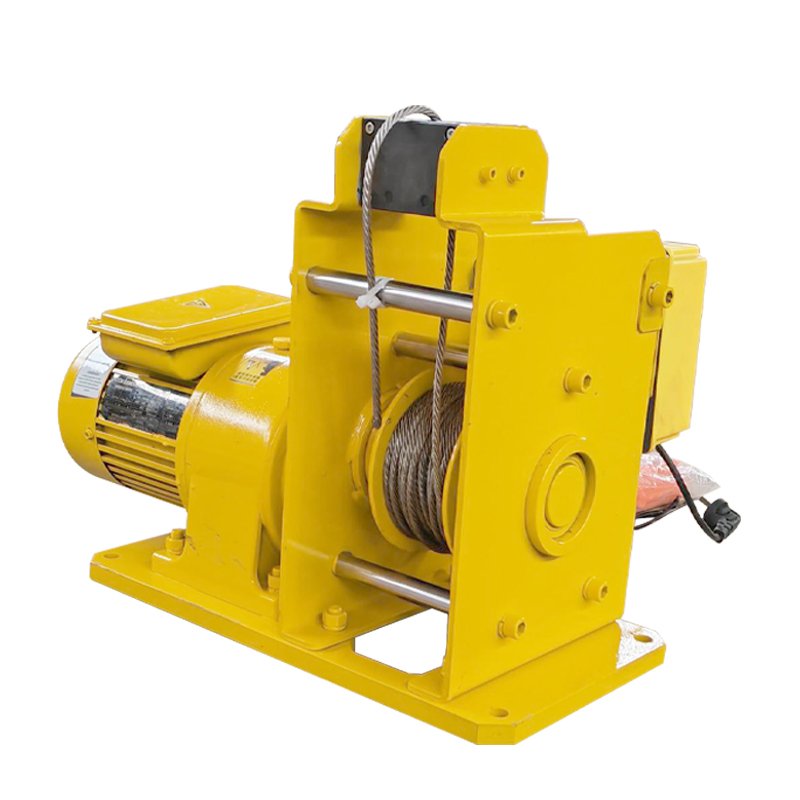

Efficient & Quiet Drive: Powered by a compact motor, ensuring stable and low-noise operation for an optimized work environment.

-

Stable Rope Guidance: Equipped with fixed rollers to keep the wire rope aligned, reducing wear and preventing deviation.

-

Electromagnetic Braking System: Provides responsive and reliable braking, enabling quick emergency stops to prevent uncontrolled descent or slippage, ensuring safety.

-

Dual Control Options: Supports both wired handle and wireless remote control, offering flexible operation for different work scenarios.

-

Universal Power Supply: Operates with single-phase 220V input, ensuring strong compatibility and efficient performance across various working environments.

Linkedin

Linkedin

Google +

Google +