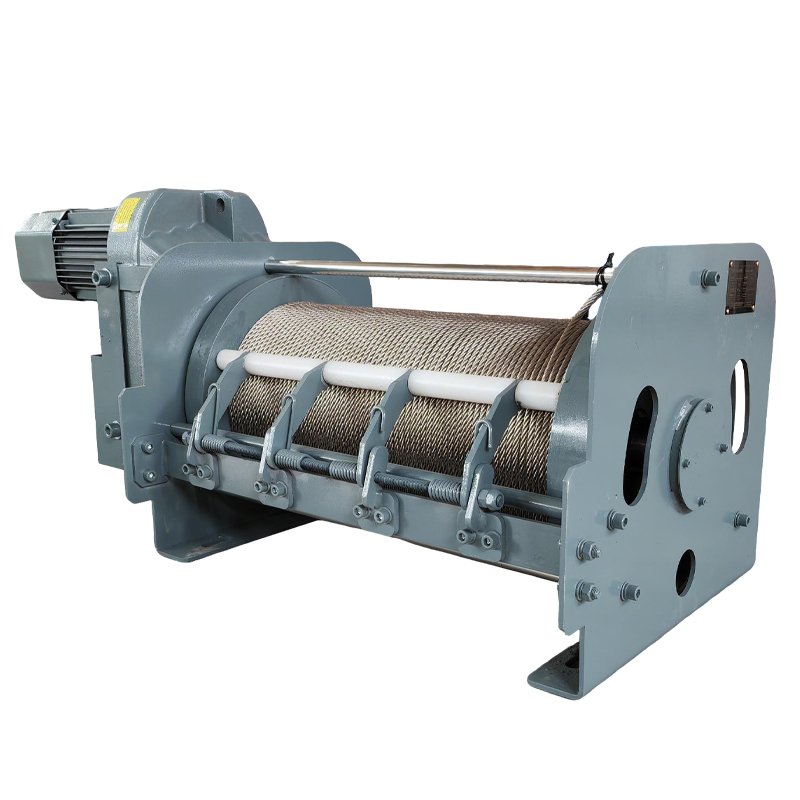

Hydraulic winch has been widely used in tow trucks. It is an important functional component, often used for lifting and towing operations. Hydraulic winches have many specifications from light to heavy. Commonly used hydraulic winches have two structural types: worm gear and planetary gear reduction. The winch is driven by a hydraulic motor, and the speed reduction device is used to achieve the purpose of reducing speed and increasing output torque, thereby achieving the relatively heavy-load traction capacity of the winch. The worm gear hydraulic winch has a relatively simple structure, is easy to make, and has relatively low transmission efficiency and production cost. It is generally used for medium and light hydraulic winches, while the planetary wheel hydraulic winch has a relatively complex structure, a large transmission ratio, and relatively high transmission efficiency and production cost. It is generally used for medium and heavy hydraulic winches.

On the tow truck, the hydraulic winch is mostly installed in the middle, and the side hydraulic winch is also gradually applied in some tow trucks. Generally, one or two winches are installed on the tow truck. According to the design requirements, the wire rope of the winch can be used in two directions of up and down rope output. In order to prevent the wire rope from being disordered, the winch should be equipped with a pressure guide rope device. The selection and installation of the winch and wire rope in the tow truck are very important. It is related to the technical and safety performance of the vehicle. Therefore, attention should be paid during installation and use:

⑴ Before installing the winch, check whether the parts are complete and whether there is any damage. If there are any parts that are damaged, they must be replaced before installation.

⑵ The connection between the winch and the connecting seat or bracket should be fixed with high-strength bolts with mechanical properties of 10.9 or above to ensure sufficient connection strength.

⑶ After the winch is installed, check whether the hydraulic pipeline is connected incorrectly, whether the clutch can be normally combined and separated, and whether the winch drum can rotate normally, and there should be no jamming.

⑷ When winding the wire rope on the winch, install the rope head into the rope hole of the drum, then tighten the set screw and put it in the rope-receiving condition. After winding 4-5 turns, load 3-5KN force to tighten the wire rope.

⑸ The maximum deflection angle of the wire rope when winding in and out of the drum should not exceed 3° to prevent the rope from being disordered and the winch force from being skewed. When it is not in use, the rope presser should press the wire rope tightly to prevent the wire rope from being loosened and disordered.

⑹ After the winch is installed, it should be run at no load before the heavy load test or when it is used again after long-term disuse, so as to facilitate the smooth operation of the motor.

⑺ It is strictly forbidden to disengage the winch clutch when lifting heavy objects or pulling. When the winch is working, the wire rope should be kept on the drum for at least 5 turns.

⑻ It is strictly forbidden to overload the winch to prevent damage to the winch and safety accidents.

● During the use of the winch of the tow truck, some faults may occur sometimes. Common phenomena are:

⑴ Oil leakage of the winch or motor. It is mainly caused by long-term use, damaged seals or loose connection bolts. Just replace the seals and tighten the connection bolts.

⑵ The separation and engagement of the winch clutch are not smooth. It is mainly caused by the misalignment of the clutch claws or the problem of the clutch operating mechanism. Turn the ring to align the claws and check and eliminate the fault of the operating mechanism.

⑶ When the winch is working, the pressure is unstable and trembling, which is mainly caused by unstable load and chaotic rope jumping of the wire rope. Just rearrange the wire rope (add counterweight to the hook to avoid unloaded rope).

The winch of the tow truck must be maintained and repaired regularly to ensure the safe use of the winch and extend the service life of the winch. The lubricating oil in the winch box should be replaced regularly, generally once a year. Always check whether the winch and motor are leaking. Always check whether the winch mounting bolts are loose, check whether the wire rope is broken, worn, or deformed, and lubricate the wire rope regularly with lubricant. If the wire rope reaches the scrap condition, it must be replaced with a new one. In general, the winch must be used, maintained, and maintained in strict accordance with the specifications in order to use the winch and the tow truck well.