KLD Kaileude | Marine Engineering Explosion-Proof Intelligent Winch System Case Study

Long-Distance Electric Winch Solution

I. Project Background

In offshore oil production platforms and marine engineering operations, high-lift hoisting systems are extensively used for critical processes such as equipment module lifting, vertical transportation of marine structures, and retrieval of long-stroke cables and wire ropes.

These applications typically feature:

- Ultra-long strokes (hundreds of meters)

- Flammable and explosive environments

- High operational continuity with minimal tolerance for error

- Demanding requirements for multi-machine synchronization and precision control

Conventional winches struggle to meet modern marine engineering's systematic demands regarding explosion-proof ratings, control precision, multi-unit coordination, and operational safety.

II. Engineering Challenges

For this offshore platform project, the client prioritized addressing these technical hurdles:

1. Safety and controllability under high-lift conditions

Long-stroke operations must prevent risks of impact, hook slippage, and brake failure.

2. Stable drive and speed regulation in explosion-proof environments

Motors and control systems must comply with offshore flammable/explosive zone regulations.

3. Reliable rope management for multi-layer wire rope winding

Extended rope lengths and multi-layer winding significantly increase risks of rope tangling, rope gnawing, and accelerated wear.

4. Precision consistency in multi-hoist synchronized lifting

Off-center loads or asynchronous operation directly expose structures to stress risks.

III. Solution

Based on actual marine engineering conditions, KLD customized a high-lift explosion-proof electric winch system specifically for offshore oil platforms, upgrading from “single equipment” to an “intelligent hoisting system.”

Core Configuration

Explosion-proof variable-frequency brake motor

Adapted for marine flammable/explosive environments, supports stepless variable-frequency speed control with smooth start/stop and high safety redundancy

PLC Intelligent Control System

Integrates multi-unit coordination logic for synchronized dual/multi-unit operation and unified dispatch control

Automatic Rope Guide + Zigzag Grooved Drum

Supports multi-layer winding of ultra-long wire ropes, ensuring orderly rope arrangement and significantly extending wire rope lifespan

Load Cell + Metering/Encoder System

Real-time acquisition of load and rope length data for closed-loop feedback control

IV. Key Technical Advantages

①High-lift structural design, engineered for extended strokes

Supports wire rope lengths reaching hundreds of meters

Ideal for continuous hoisting, retrieval, and vertical lifting operations

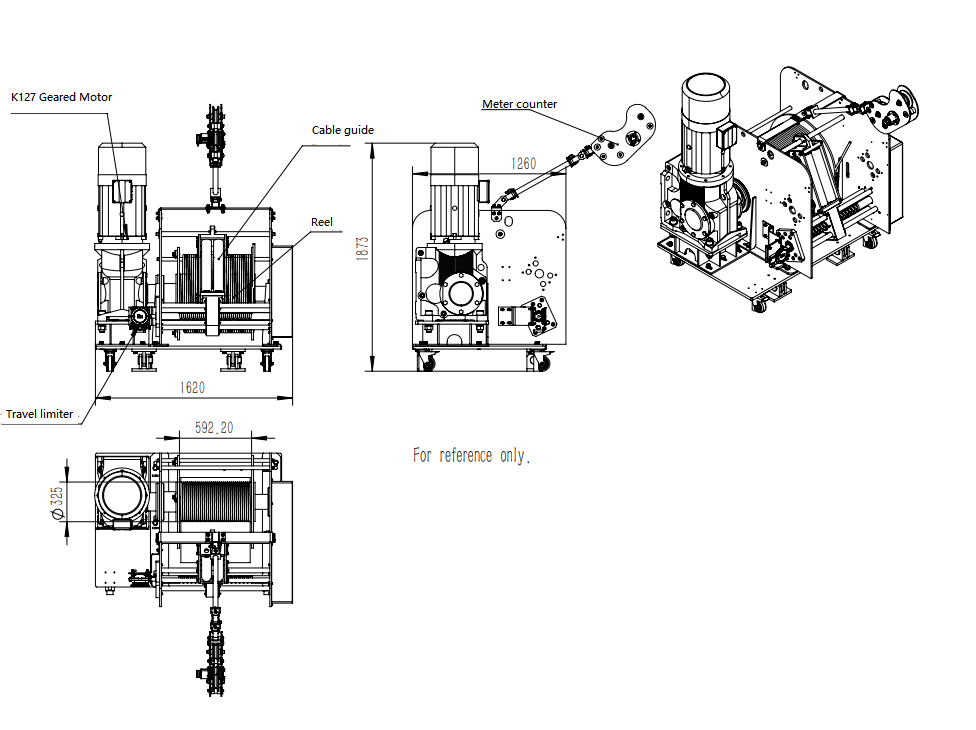

2534 Assembly Winch 2T2025.12.1

② Explosion-proof variable frequency drive, compliant with offshore safety standards

Explosion-proof motor + variable frequency braking

Reduces start-up impact, enhancing system safety redundancy

③Multi-layer orderly rope arrangement ensures stable operation

Deep integration between rope guide and drum structure

Prevents rope tangling, groove jumping, and localized wear

④Closed-loop data feedback for precise control

Real-time monitoring: load / stroke / speed

Provides reliable data foundation for multi-unit synchronization and safety interlocking

⑤Multi-unit synchronized control adapts to complex lifting scenarios

PLC achieves millisecond-level response

Ensures consistent multi-point force distribution, preventing load imbalance risks

| Model: 2000 KG | Rated Pulling Force: 2000kg | Wire Rope Diameter: 16mm |

|---|---|---|

| Motor Power: 22kw | Drum Speed: 23rpm | Average Rope Speed: 35m/min |

| Rope Length: 480m | Self Weight: 2700kg |

V. Customization Capabilities

As a global provider of comprehensive industrial winch solutions, KLD offers deep customization tailored to offshore platform requirements:

✅ Custom cable retrieval speed

✅ Custom wire rope diameter and length

✅ Custom operation modes (single-unit / multi-unit synchronized)

✅ Custom rated load, travel limits, and control logic

✅ Explosion-proof rating and voltage standard adaptation

VI. Project Value and Outcomes

Through this customized solution, the client achieved:

✔️ Full safety control throughout high-lift hoisting operations

✔️ Significantly enhanced multi-unit synchronization precision

✔️ Extended wire rope lifespan and operational reliability

✔️ Comprehensive improvement in platform hoisting efficiency and operational stability

This solution has become a standardized reference case for winch system selection on offshore oil production platforms.

FAQ|Common Questions on Offshore Platform Winches

Q1: Why must offshore oil platforms use explosion-proof winches?

A: Combustible gas environments on offshore platforms pose ignition risks with standard motors, making explosion-proof winches a mandatory safety requirement.

Q2: What is the typical stroke length for high-lift electric winches?

A: Customizable per project. Common ranges are 300–600m, with some projects exceeding this based on wire rope specifications and drum design.

Q3: Is an automatic rope payoff system essential in offshore applications?

A: Absolutely. Without a payoff system, extended rope lengths and multi-layer winding conditions significantly compromise safety and rope lifespan.

Q4: How is precision ensured in multi-winch synchronization?

A: Through PLC control combined with real-time feedback from encoders/force sensors, forming a closed-loop control system to maintain controllable synchronization error.

Q5: Does KLD support non-standard customization?

A: Yes. KLD possesses its own manufacturing facilities and engineering team, specializing in deep customization for marine engineering and heavy-duty applications.