KLD Kaileude Self-Rope-Guiding Industrial Winch|High-Precision Traction and Orderly Rope Retraction Solution

I. Product Overview: Why Self-Rope-Guiding Winches Are Essential in Industrial Settings

In industrial applications such as traction, lifting, positioning, and slideway assistance, issues like tangled ropes, rope stacking, and groove jumping have long been core problems affecting equipment safety and efficiency.

Self-Rope-Guiding Industrial Winches fundamentally resolve multi-layer rope management challenges at the mechanical level through a structural combination of “grooved drum + reciprocating screw rope guide + variable frequency drive.”

This series employs variable frequency brake motors for smooth, low-noise operation suitable for continuous duty. With IP56 protection rating, it delivers long-term stability in outdoor and demanding environments.

1. Self-Rope-Guiding Structure: Orderly Multi-Layer Winding

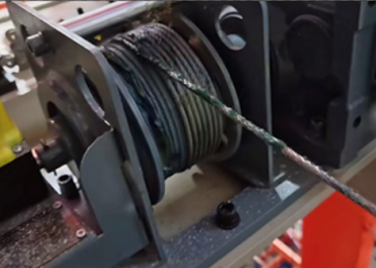

Grooved Drum Design

The drum surface features precision-machined standard grooves that guide the wire rope along a predetermined path, preventing groove jumping and uneven wear.

Recirculating Screw Rope Guide

Synchronized with the drum, the rope guide automatically ensures uniform rope distribution during multi-layer winding, achieving:

No tangling

No rope compression

No layer separation

This structure is particularly suited for industrial applications requiring long strokes and large rope capacities.

2. Variable Frequency Drive System: More stable traction, more precise control

Equipped with a variable frequency brake motor, offering the following advantages:

Smooth starts and stops, reducing impact loads

Low operating noise, suitable for laboratory and factory environments

Adjustable speed precisely matches operational cycles

Offers significant advantages over conventional fixed-speed winches in applications requiring precise positioning and constant-speed traction.

3. Industrial-Grade Protection: Suitable for Outdoor and Harsh Environments

Achieves IP56 protection rating, featuring:

Dust resistance

Resistance to high-pressure water jets

Stable operation in outdoor rain environments

Can be installed directly outdoors without additional protective covers

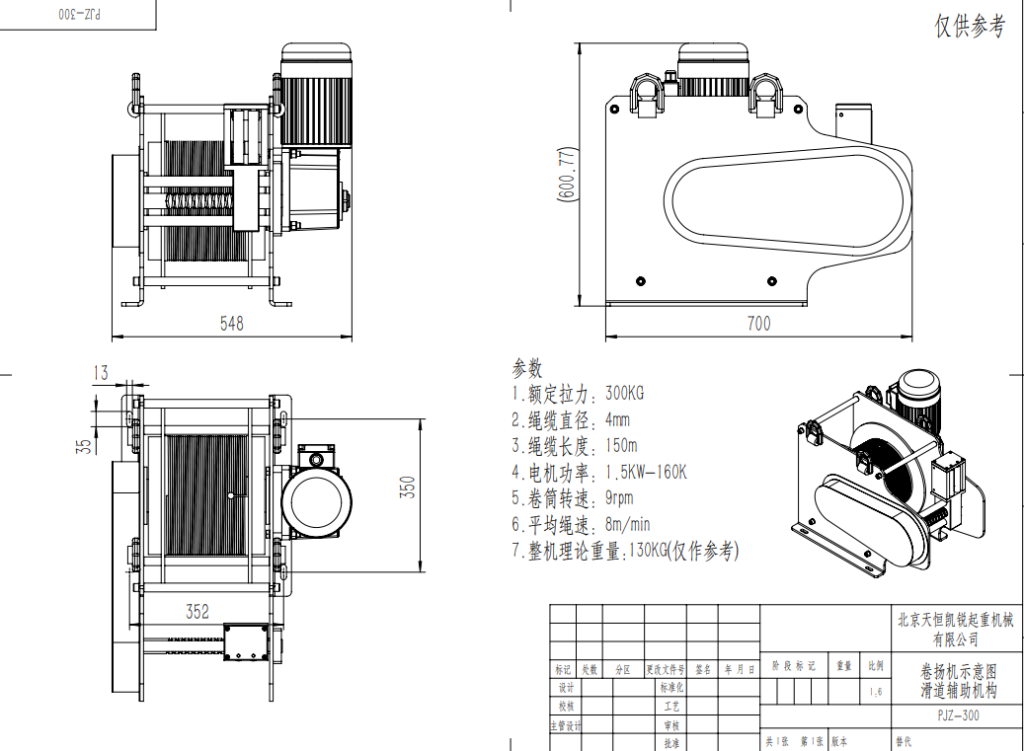

II. PJZ-300 Slide Rail Assist Winch Parameter Example

Taking the PJZ-300 Slide Rail Assist Winch as an example, its key technical parameters are as follows:

| 型号:300 KG | 额定拉力:300kg | 钢丝绳直径:4mm | 绳长:150m |

| 电机功率:1.5kw | 卷筒转速:9rpm | 平均绳速:8m/min | 整机理论重量:约 130 kg |

This model is commonly used for slideway assistance, traction positioning, and synchronized mechanism movement. Structural parameters serve solely as engineering selection references.

III. Typical Application Scenarios

Industrial equipment traction and retrieval

Slideway/guide rail auxiliary mechanisms

Tooling platform movement and positioning

Outdoor Lifting and Tensioning Systems

Long-stroke, Multi-layer Winding Winch Requirements

IV. Customization Services Available

This series of self-laying industrial winches supports parameter customization per project requirements, including but not limited to:

Rated Load

Rope Capacity

Rope Release/Retrieval Speed

Travel Limit

Voltage Rating

Mounting Configuration

Accommodates non-standard operating conditions and system integration needs.

FAQ

Q1: What distinguishes self-laying winches from conventional winches?

A: Self-laying winches employ rope grooved drums and reciprocating rope guides for active rope management, maintaining wire rope order during multi-layer winding. Conventional winches often suffer from tangled or stacked ropes, resulting in compromised safety and reduced service life.

Q2: Will wire ropes become compressed or knotted during multi-layer winding?

A: No. The reciprocating screw rope guide operates synchronously with the drum, ensuring uniform arrangement of each rope layer and preventing compression or knotting.

Q3: Is the equipment suitable for long-term outdoor use?

A: Yes. With an IP56 protection rating, it offers dustproofing and resistance to powerful water jets, making it suitable for direct outdoor operation.

Q4: Can the winch speed be adjusted?

A: Yes. Equipped with a variable frequency drive system, it allows flexible speed adjustment based on operational requirements, enabling smooth starts and stops.

Q5: Does it support non-standard customization?

A: Yes. Customization is available for pulling force, rope capacity, speed, voltage, and structural design according to specific project needs.