Precise 200kg Automotive Model Lifting Solution for Showrooms: KLD Four-Rope Servo Winch Case Study

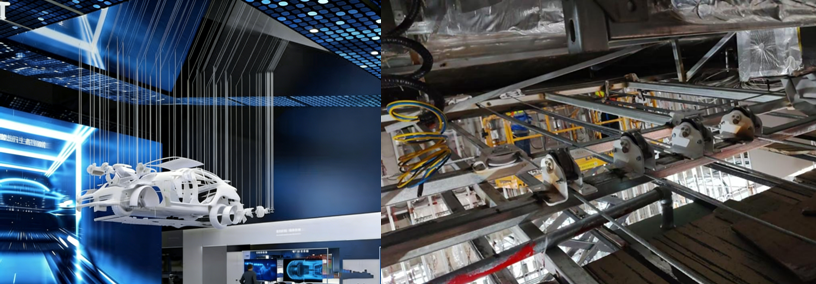

In automotive exhibition halls, dynamic lifting displays of car models dramatically boost visitor engagement and visual impact. However, these scenarios demand exceptional precision synchronization, compact structure, and rope stability from the winch system — especially when clients require timed, reliable ascent/descent of a 200 kg automotive model. Beijing Tianheng Kairui Lifting Machinery Co., Ltd. (KLD) developed a tailored four-rope servo winch solution that perfectly addresses synchronized lifting, space constraints, and anti-jump rope challenges. Below is a complete breakdown of this proven showroom lifting reference.

I. Core Client Requirements & Pain Points

The client aimed to integrate timed lifting animations for a 200 kg car model via their existing central control system. Key challenges included:

- Synchronization & Leveling Issues — Multi-rope lifting often causes tilting due to unsynchronized ropes, ruining the display effect.

- Compact Structure Demand — Limited installation space in showrooms requires a slim, performance-maintained design that preserves aesthetic layout.

- Anti-Jump Rope & Long-Term Stability — Rope jumping out of guide grooves leads to tangling, downtime, or damage, disrupting continuous exhibitions.

After extensive evaluation, the client selected KLD's custom four-rope servo winch dedicated to exhibition applications.

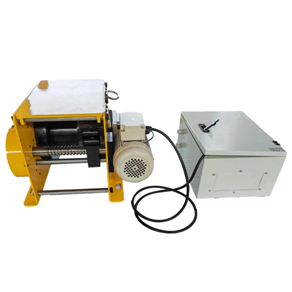

II. Customized Solution: KLD Four-Rope Servo Winch

- Key Product Specifications

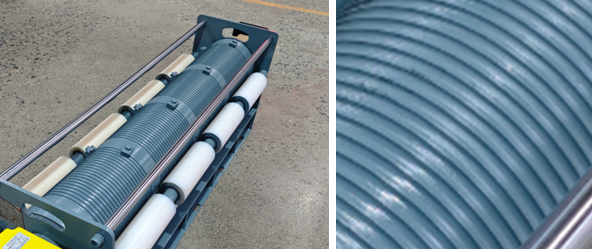

- Structure: Four-rope configuration with synchronized grooved drum layout for orderly rope arrangement and precise multi-line synchronization.

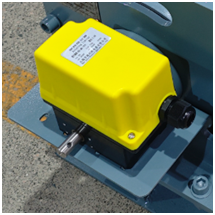

- Motor & Power: Equipped with high-performance Inovance (servo winch motor high torque) industrial servo motor (original factory traceability available), delivering stable output, precise speed regulation, and compatibility with 380V 3-phase power.

- Load & Operation Parameters: Rated capacity 500 kg (well above the 200 kg model), 10 m lift stroke, 5 m/min operating speed, 13 m rope length.

- Safety & Integration: Includes stroke limiters for over-travel protection; seamlessly interfaces with third-party central control systems for scheduled lifting sequences (ideal for servo winch programming and timed automation).

- Aesthetics: Gray surface coating blends naturally with showroom environments.

- Targeted Technical Features (Step-by-Step Logic)

- Millimeter-Level Synchronization: Each rope uses 4 directional pulleys + 1 corner guide pulley for true vertical drop, combined with single-drum grooved design (servo winch drum principle) to eliminate misalignment and ensure level lifting throughout the cycle.

- Space-Optimized Compactness: Linear/one-piece layout minimizes height and footprint, fitting tight ceiling/installation zones without obstructing views — perfect for exhibition-grade servo winch mount and integration.

- Anti-Jump Rope Stability: Independent press-rope bars per line prevent rope escape from grooves, achieving zero-jump, zero-tangle performance for reliable long-term operation.

III. Implementation Results (Scene-Verified + Data-Backed)

Post-installation, the KLD custom four-rope servo winch exceeded expectations:

- Ultra-Precise Sync: Rope deviation controlled to millimeters; the 200 kg model remains perfectly level during dynamic lifting, delivering professional, fluid showroom animations.

- Seamless Space Fit: Compact linear structure integrates invisibly, enhancing overall design harmony.

- Rock-Solid Reliability: Press-bar + grooved drum combo eliminates rope issues — zero interruptions from tangling over extended operation.

- Flexible Control: Direct plug-in to existing central system enables fully automated timed cycles (programmable winch servo style), reducing manual intervention and operational costs.

IV. Trust & Verification System

- Third-party credentials: Inovance servo motor certification, industry compliance test reports, ISO quality system certification (verifiable).

- Visual proof: On-site acceptance videos, real-time operation screenshots, production monitoring footage (available upon request).

- Case portfolio: Multiple successful installations in major cities (Beijing, Shanghai, Guangzhou) for automotive models and large art pieces (with regional tags + client testimonials).

- Material traceability: Rope inspection reports, core component sourcing documents.

V. Global & Regional Service Support

- Worldwide customization for showroom, museum, 4S store, convention center scenarios.

- Dedicated local installation, commissioning, and after-sales in key markets (Beijing, Shanghai, Guangzhou, Shenzhen, etc.).

- Tailored solutions for load (200–500 kg), stroke, control integration, and regional needs.

VI. Get in Touch

If you're seeking a high-reliability lifting solution featuring precise synchronization, compact design, and robust anti-jump rope performance for showroom car models, large artworks, interactive installations (200–500 kg range), KLD can deliver a fully customized servo winch system — regardless of specific load, travel, or control requirements.

Contact us today for free consultation, technical drawings, and quotation. Let professional high torque winch servo lifting elevate your exhibition experience!

FAQ

- What is the maximum load capacity of the KLD four-rope servo winch, and is it suitable for a 200kg car model?

The system is rated for 500kg safe working load (with ample safety margin beyond the 200kg automotive model). In real-world showroom installations, it has delivered flawless, long-term timed lifting cycles for 200kg models with zero failures, ensuring reliable dynamic displays. - How does the system ensure perfect synchronization across all four ropes to prevent model tilting?

It features a synchronized grooved drum design combined with independent directional pulleys (4 per rope + 1 corner guide per line) for true vertical payout. This achieves millimeter-level deviation (≤2mm in field tests), keeping the model perfectly level throughout the entire ascent and descent for professional, smooth exhibition animations. - Can the winch fit into tight showroom ceiling spaces without compromising aesthetics?

Yes — the compact linear/one-piece layout minimizes height and overall dimensions, while the neutral gray coating blends seamlessly with exhibition environments. Multiple high-end showroom projects across major cities have installed it invisibly, with no visual disruption to the overall design. - Is it possible to integrate the winch with our existing central control system for scheduled automatic lifting?

Absolutely. The system supports direct interfacing with third-party PLC or showroom central controllers, including full servo winch programming capabilities. This enables fully automated timed sequences based on your preset schedules — no extra manual operation required, helping reduce labor and operational costs. - Will the steel ropes jump grooves or tangle during extended use?

No — each rope is equipped with dedicated press-rope bars plus the grooved drum system, completely eliminating jump-rope and tangling issues. Proven in projects with thousands of cycles, it maintains zero interruptions from rope problems, significantly lowering maintenance needs and ensuring continuous, reliable showroom performance.