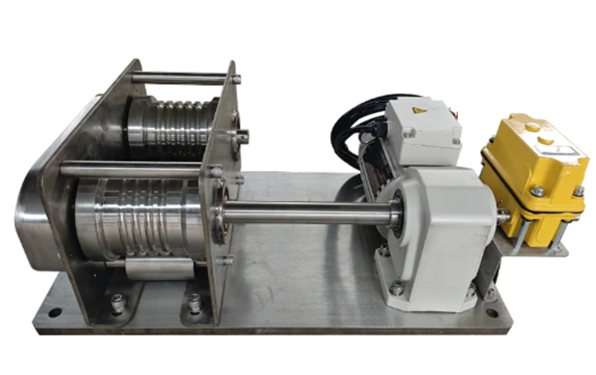

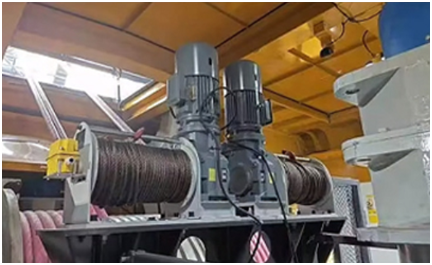

Servo-driven double drum winch with closed-loop control, encoder feedback, and PLC/HMI integration. Synchronized drums for precise lifting/pulling, long-travel options, level-wind, and safety brakes. Get specs, price, and lead time.

Engineered for applications that demand perfectly matched motion on two drums, this servo-driven double-drum winch delivers closed-loop control, high repeatability, and safety-first design. Whether you need synchronized lifting of large fixtures, constant-speed pulling for test benches, or long-travel positioning with accurate length feedback, we build the package to your spec — drums, rope path, control cabinet, and HMI included.

Why choose a servo double drum winch

- True synchronization (master/slave or electronic gearing)

Two drums run in precise sync with encoder feedback; configurable for equal speed, equal length, or ratio-based control for asymmetric loads.

- Closed-loop accuracy

Servo drive + encoder keeps your target speed/position even under varying loads. Excellent for labs, endurance lines, and delicate fixtures.

- Constant speed / constant tension modes

Switchable logic lets you hold a target line speed or maintain a defined tension window where your process requires. - Built-in safety

Electromagnetic or fail-safe braking, torque limits, upper/lower travel limits, e-stop chain, and interlocks for doors/guards/light curtains.

- Industrial HMI & I/O

Touch HMI for setpoints, recipes, diagnostics. PLC/SCADA connectivity (digital/analog I/O, Modbus/Profinet/Ethernet/IP per request).

- Serviceable, modular design

Split bearing housings, accessible brake, and quick-change wear parts shorten downtime and simplify maintenance.

- OEM/ODM flexibility

Drum groove pattern, level-wind, rope diameter, gear ratio, protection rating, and finish can all be tailored to your site and standards.

Typical configurations (indicative examples)

| Model | Rated Pull (per drum) | Line Speed (per drum)* | Drum Options | Rope (Ø × layer) | Drive/Brake | Control |

| SDW-1T-HS | 1 ton | 10–30 m/min | Grooved, single-layer | Ø8–10 mm × 1–2 | Servo + electromagnetic | HMI + PLC, encoder length/speed |

| SDW-3T-VFD | 3 ton | 6–20 m/min | Grooved + level-wind | Ø12–14 mm × 2–3 | Servo + fail-safe brake | Master/slave sync, tension/speed modes |

| SDW-5T-LT | 5 ton | 4–12 m/min | Long-travel, split-reel | Ø16–20 mm × 3–4 | Servo + hydraulic buffer brake (opt.) | SCADA I/O, data logging |

*Speed ranges are adjustable via the drive; final setpoints are tuned to your duty cycle, inertia, and safety margins.

What we customize: drum width/diameter/groove, level-wind (mechanical or servo), rope guides, encoder type (incremental/absolute), braking scheme, cabinet layout, field wiring, terminals, and HMI language.

Applications

- Synchronized lifting of large trays, jigs, and tooling (two-point or four-point systems with sheaves)

- Test lines / durability labs requiring constant speed or measured length under changing loads

- Long-travel pulling/positioning with accurate pay-in/pay-out metering

- Stage/rigging & process positioning where smooth start/stop and repeatability are critical

- Assembly and conveyor assists, equalizing multiple pick points to protect structures

What affects price & lead time

- Rated loads & duty (continuous vs. intermittent; thermal sizing of motors/brakes)

- Speed/acceleration profile (servo sizing, inertia compensation, encoder selection)

- Rope capacity & drum geometry (long-travel, groove pattern, level-wind mechanism)

- Control stack (HMI/PLC brand, safety PLC, SCADA protocol, tension cells)

- Materials & environment (stainless/coatings, IP55–IP65, temperature range)

- Compliance & documentation (FAT, load test, certificates, wiring docs, manuals)

Standard features

- Dual encoders (per drum) for length & speed feedback

- Servo drive with soft start/stop and jerk-limited ramps

- Electromagnetic or fail-safe braking with brake release monitoring

- Upper/lower limit switches, over-travel protection, e-stop circuit

- Industrial control cabinet (powder-coated steel or stainless), labeled terminals, full schematics

- Pendant and/or wireless remote (enable/disable, jog, speed presets)

- Event & alarm logs for maintenance traceability

Options & accessories

- Level-wind (spreader bar / screw type) for perfect layering on long travel

- Tension measurement (load cells) with control integration

- Guide sheaves, anchors, rope thimbles, and line contactors

- Safety PLC with light curtain/door interlocks

- SCADA dashboards for real-time speed/tension/length, recipe management

- Stainless-steel build, marine coatings, heaters for low-temp sites

- Energy chain & cable routing kits for clean installations

RFQ checklist (copy/paste and fill out)

- Number of drums (2 by default) and synchronization mode (equal speed / equal length / ratio)

- Rated pull per drum (kN/ton) and duty cycle (S-class)

- Target speed (m/min), ramp profile, and braking requirements

- Rope diameter & total travel (m); need level-wind or specific groove pattern?

- Power (voltage/frequency), preferred brands for drives/PLC/HMI

- Safety & compliance (limits, e-stop, guards, documentation, test plans)

- Environment (indoor/outdoor, temperature, dust/splash, stainless/IP needs)

- Mounting (footprint, base frame, access, lifting points)

- Timeline (target ship date) & packaging (export crate, sea/air)

Send the checklist and any drawings (layout, P&ID, I/O map). We’ll return a tailored spec, itemized quote, and production schedule that matches your project.

FAQ

Q1: How precise is the synchronization between drums?

With dual encoders and servo control, the controller holds the commanded differential tightly. For equal-length mode we use encoder counts calibrated to rope circumference; for ratio mode we electronically gear the drums.

Q2: Can the system maintain a target tension instead of speed?

Yes. We integrate load cells and apply a tension loop; the controller will modulate torque/speed to stay within the set tension band.

Q3: What happens during an e-stop or power failure?

Brakes engage, drives ramp down under defined safety sequences, and the PLC records the event. Optional UPS keeps the controller alive for orderly stop and data capture.

Q4: Can I integrate this with my line PLC/SCADA?

Absolutely. We expose I/O and support mainstream protocols. Recipes, setpoints, and status tags can be mapped to your DCS or MES.

Q5: Do you support stainless builds for harsh environments?

Yes. We offer stainless cabinets and hardware, sealed bearings, and enhanced coatings for marine or wash-down conditions.