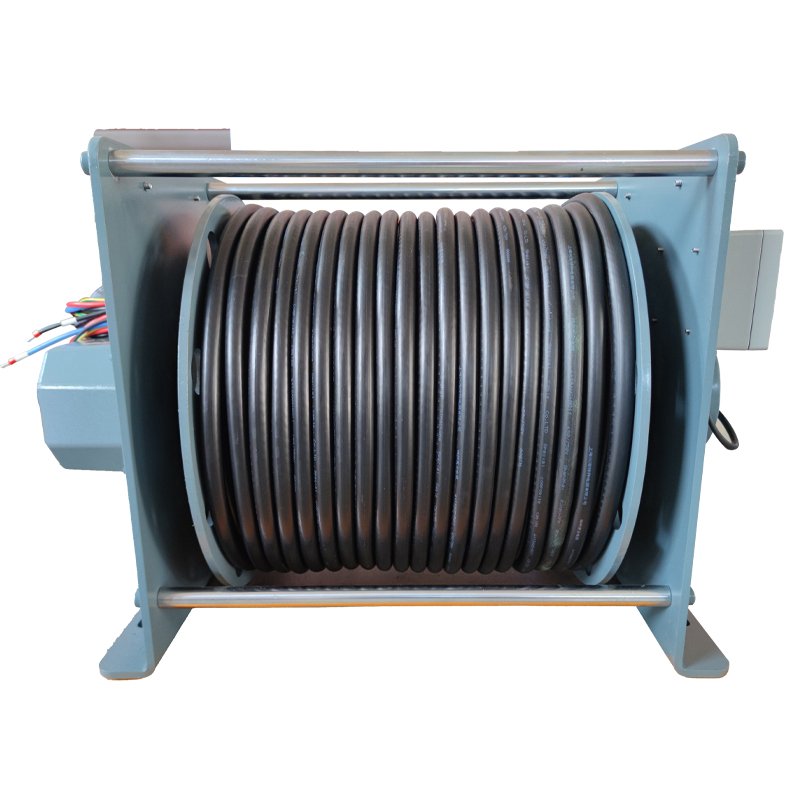

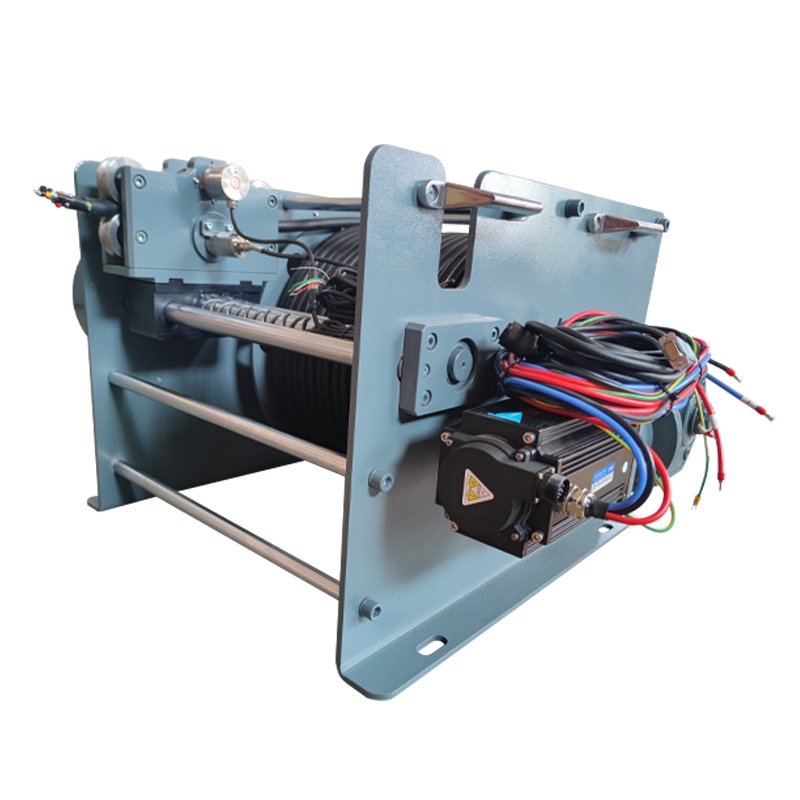

Designed for the most demanding environments, our Industrial Servo Winch redefines cable management in mining, port logistics, and industrial automation. Unlike traditional winches, this system utilizes a high-precision servo motor drive coupled with advanced PLC integration to deliver constant tension control and sub-millimeter positioning accuracy.

Whether you are managing shore power connections or deploying sensor equipment in deep mines, our winch ensures operational safety with real-time feedback on cable length and load tension.

Linkedin

Linkedin

Google +

Google +