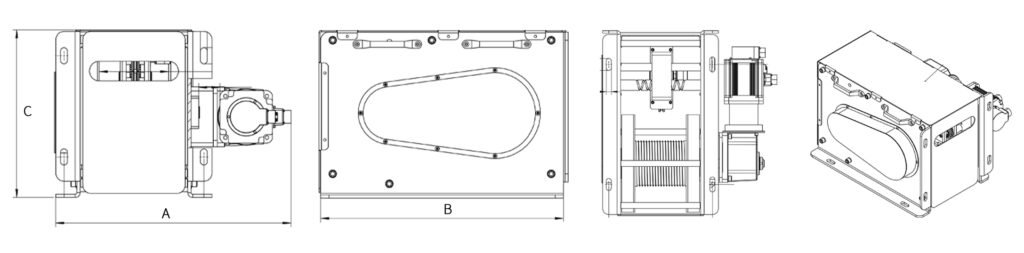

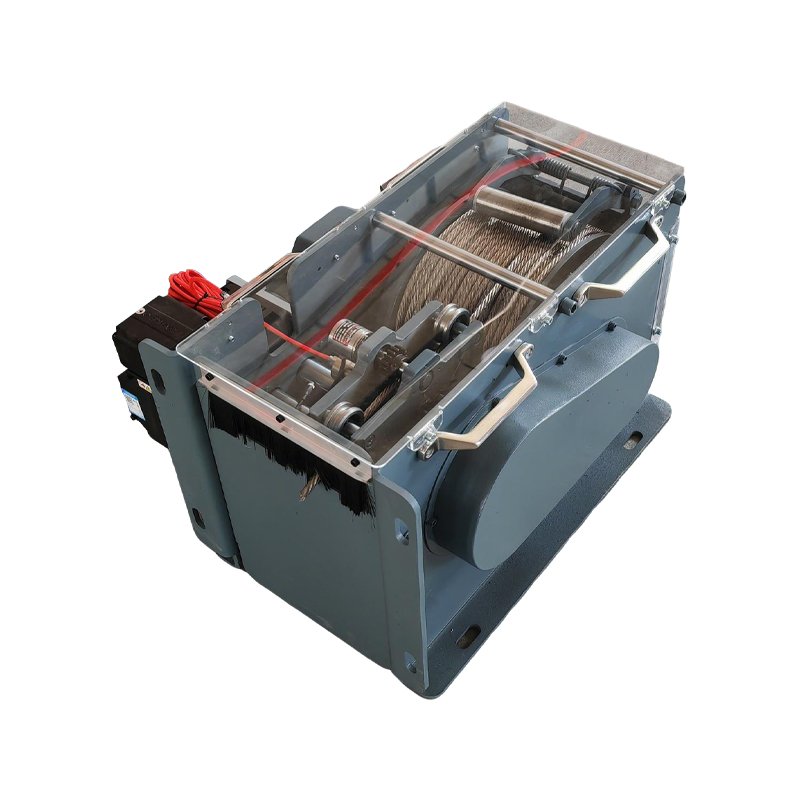

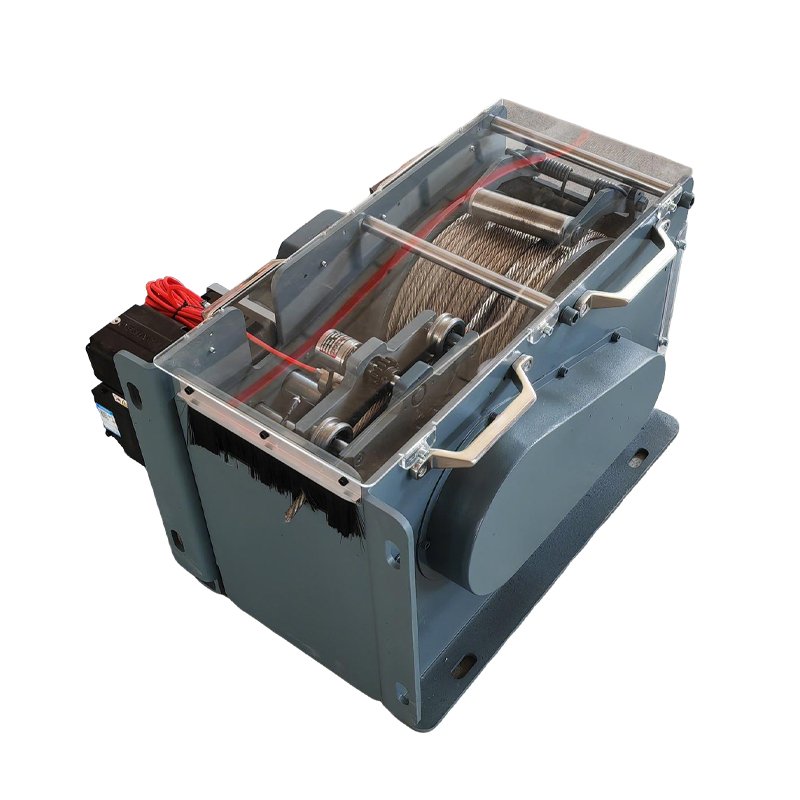

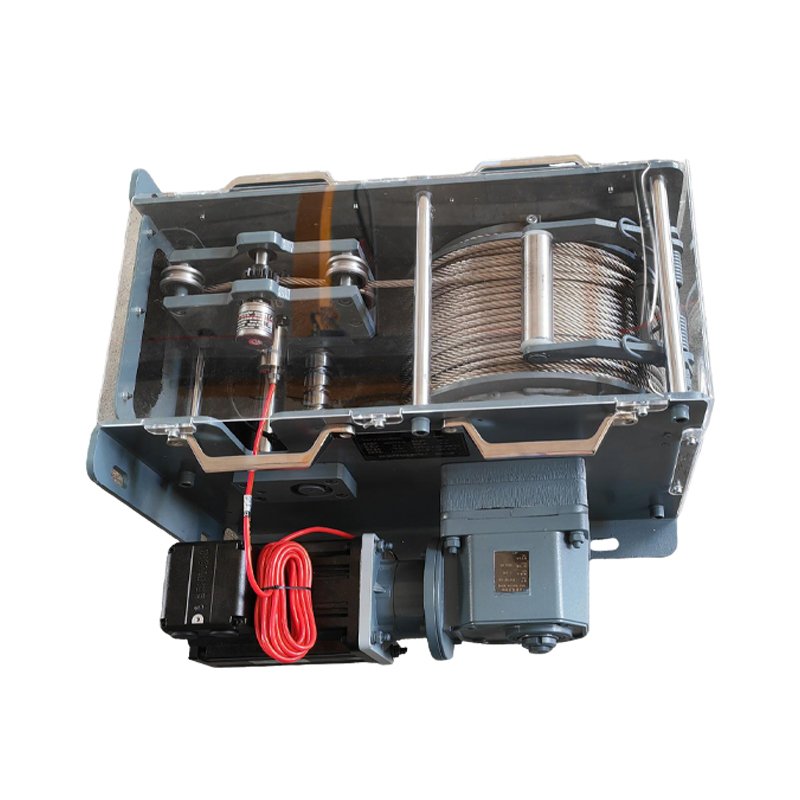

This servo winch, custom-developed for Harbin Institute of Technology, features ahigh-performance Delta servo motor as its core drive. Equipped with an automatic rope arranger and rope pressing device, it ensures efficient payout and stable retrieval of the rope, effectively preventing tangling even under slack conditions. The integrated system includes a length-measuring encoder and force sensor to monitor rope length, speed, and tension in real time. Critical data is fed back to the PLC control system, enabling intelligent operation and precise process control. This device is widely used in high-precision experimental applications such as humanoid robot testing fixtures.

The product can be customized according to cable retrieval speed, rope length, and operating mode, and is compatible with both single-phase and three-phase AC power systems for user selection.

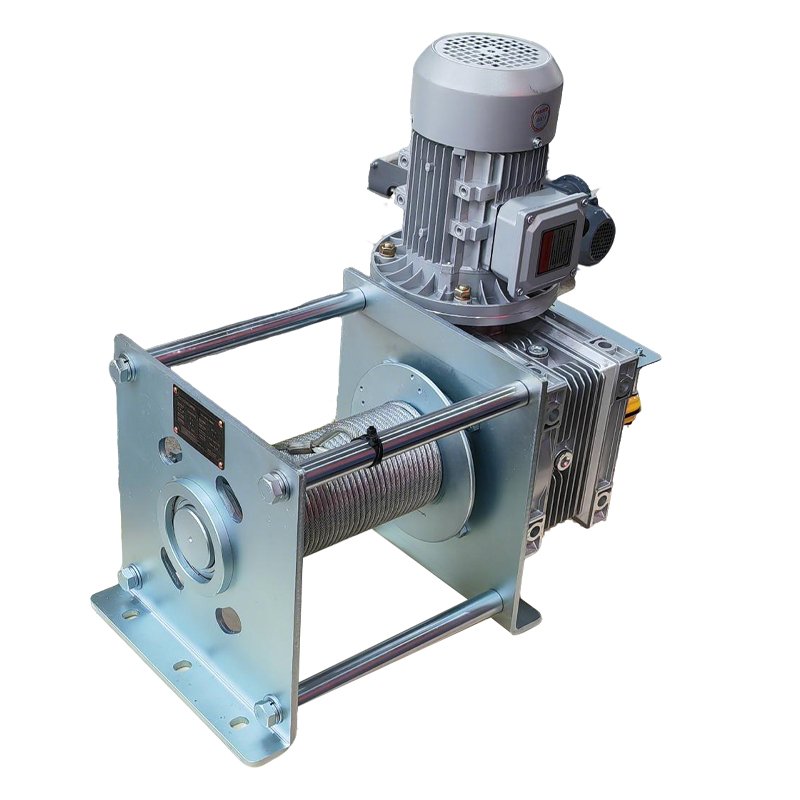

- Servo drive system:Fast response and high precision ensure smooth rope payout.

- Automatic rope arrangement Pressing system:Orderly rope arrangement prevents tangling and knotting, enhancing system stability.

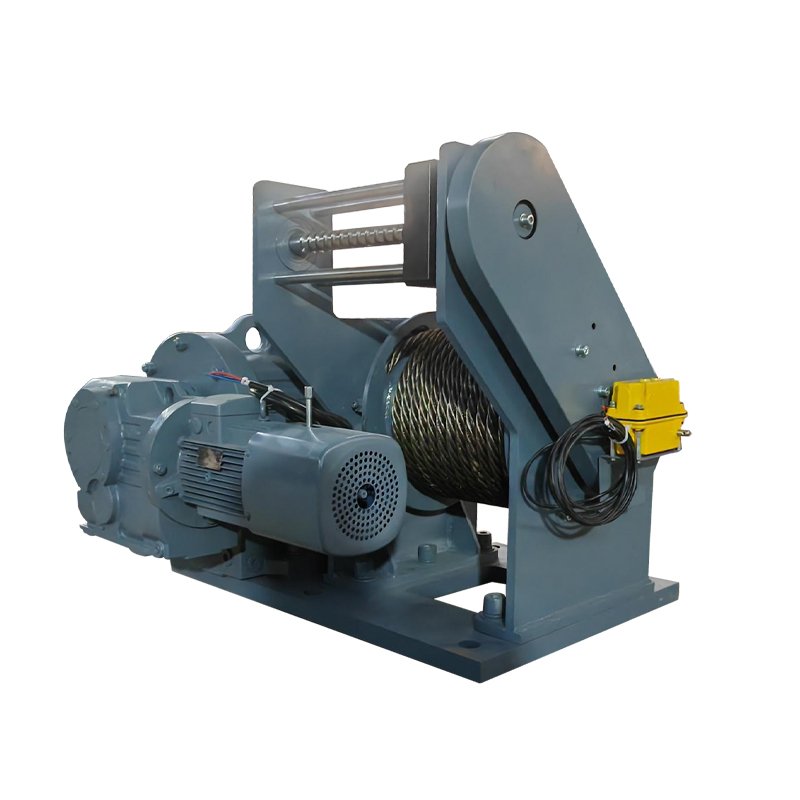

- Length-measuring encoder and densor:Accurately monitors rope length, speed, and tension, with real-time feedback on operational status.

- Supports PLC automatic control:Real-time data acquisition meets the automation requirements of complex testing procedures.

- Customized development:Tailored for the humanoid robot testing scenarios at Harbin Institute of Technology, offering strong adaptability.

Linkedin

Linkedin

Google +

Google +