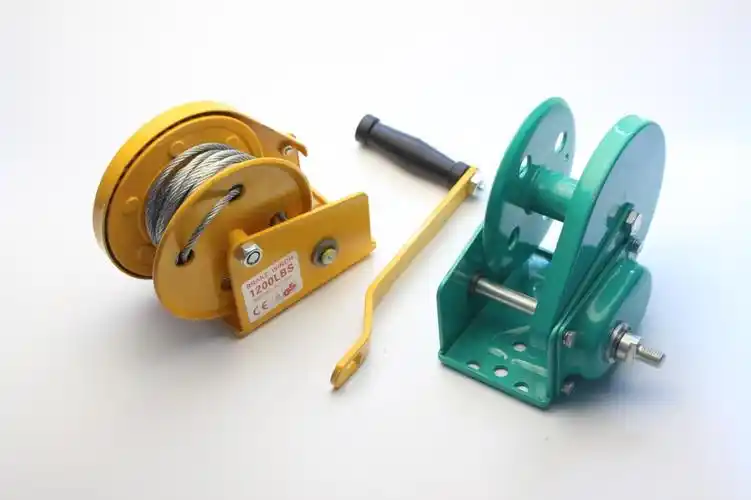

The manual winch brake plate and the thickened bottom pad are made from high-quality steel. However, these are only semi-finished products and require further processing through techniques such as electrostatic powder coating and galvanized plating. These coating processes apply colored paint to the surface of the steel, not only enhancing the aesthetic appearance but also improving the steel's durability and service life.

In factory coating processes, the two most common methods are electrostatic powder coating and galvanized plating. What are the differences between them?

Electrostatic Powder Coating

This process uses static electricity to spray colored powder onto the surface of the winch's semi-finished product. The result is a winch with a variety of colors, offering better aesthetics.

Galvanized Plating

The galvanizing process involves coating the semi-finished winch product with a layer of zinc. While the color is single, and it may not be as visually appealing as the powder coating, galvanized plating offers superior rust resistance compared to electrostatic powder-coated winches.

Therefore, when purchasing a manual winch, customers should choose the appropriate product based on their work environment. For general conditions, a winch with an electrostatic powder coating is suitable. However, for damp or humid environments, a winch with galvanized plating should be chosen for better corrosion resistance.