Two-Speed Manual Winch Selection & Application Guide | KLD Manual Winch Manufacturer

After years of project experience, I’ve increasingly realized that

not every working condition is suitable for a high-power electric winch.

Some sites do not have reliable power supplies, some have extremely limited space, some require only intermittent pulling/lifting, and in many scenarios operators actually prefer having “visual feedback and tactile control” rather than relying entirely on electric or automatic systems.

Under these conditions, a two-speed manual winch—mechanically reliable, dual-speed capable, and able to interface with electric or pneumatic tools when needed—often becomes a more practical solution than “installing an electric winch or servo system.”

From the perspective of both a manufacturer and an engineer, I will explain this type of two-speed manual winch from two angles: selection/purchasing and application scenarios/solution design, so you can have a complete reference when making inquiries or comparing options.

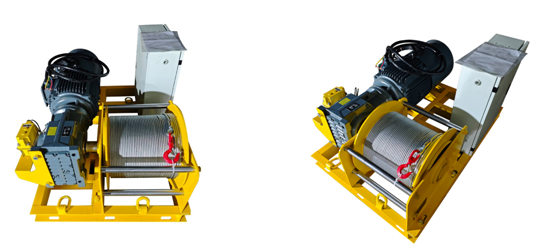

I. What Does This Type of Two-Speed Manual Winch Look Like?

Let’s begin with the basic design logic of this product.

Dual-Speed Structure

- When under no load or light load, you can shift into high gear, which allows faster rope retrieval/release and saves time spent cranking.

- Under heavy load, shift to low gear—higher reduction ratio, higher torque, easier to crank, and far safer.

Manual Operation with “Semi-Electric” Possibility

Although it is positioned as a hand winch, the structure is designed with the option to interface with

electric wrenches or pneumatic tools.

In other words, for repetitive motions, you can use a tool to assist instead of cranking manually—improving efficiency while keeping the system fundamentally simple and reliable.

Compact Size and Flexible Installation

Different capacities have different outer dimensions, but we always try to minimize overall size.

Supports vertical or horizontal mounting, making it easy to install on walls, frames or platforms.

Load Range: 500–5000 kg

The standard series covers loads from several hundred kilograms up to several tons.

Wire rope diameter and drum capacity match the load rating, meeting the majority of small to medium manual pulling and lifting needs.

This is the design intention of our two-speed hand winch:

maximize efficiency, safety and versatility without introducing complex electrical controls.

II. From a Selection/Purchasing Perspective: How Do You Choose the Right Two-Speed Manual Winch?

1. First clarify “what you need to do”—not “how many tons you want.”

Whenever a customer asks, my first question is always:

“Is it for pulling, lifting, or tensioning/positioning?”

Horizontal or inclined pulling:

Moving carts, pallets, tooling platforms or equipment modules along the ground or on rails.

Vertical or near-vertical lifting:

Lifting equipment parts, modules or maintenance components.

Tensioning and positioning:

Cable tensioning, hose/cable take-up, fixture positioning during assembly, etc.

Different tasks require different safety factors, braking types, rope diameters and rope speeds.

If you tell us upfront “mainly horizontal pulling” or “mainly vertical lifting,” we can give far more accurate recommendations.

2. How to choose the rated load? Don’t assume “bigger is always safer.”

Many people simply ask for a “1-ton” or “2-ton” winch.

A more accurate approach is to provide:

- Maximum weight of the object being pulled/lifted

- Whether it’s a rolling load (wheels, rails) or a sliding load (dragging on ground)

- Whether there is a slope, and how steep

- Whether sudden blocking or impact loads may occur

We will calculate the actual required pulling force and recommend a suitable load rating with proper safety factor.

In short:

- Do not “overload a small winch,”

- But also do not oversize excessively just for peace of mind—this increases cost and size unnecessarily.

3. Make full use of the value of “two speeds”—when to use which?

The essence of a two-speed manual winch is separating speed and control.

High-speed gear:

Used for fast rope release/retrieval under no load or light load—e.g., sending the hook to position or retrieving excess rope after work.

Low-speed gear:

Used when approaching rated load or requiring slow, steady pulling/lifting—more torque, less effort, and better fine control.

If your operation includes long idle travel (e.g., sending the hook out several meters before loading), the dual-speed mechanism is extremely valuable:

you won’t need to use slow gear for the entire distance, nor compromise safety for speed.

4. Don’t overlook rope diameter and drum capacity

Different load ratings correspond to different wire rope diameters and drum capacities.

During selection, we need to confirm:

- Your required effective travel

- Safety wraps required on the drum

- Whether travel may increase in future upgrades

Some projects reserve only “just enough” travel at the beginning, but when the production line changes later, they want “a bit farther.”

If no allowance was planned early, modifications become troublesome.

5. Installation space: will it fit inside your equipment/site?

Manual winches are simple, but they still require space.

Dimensions differ significantly between models; we provide full L×W×H and mounting hole details on drawings.

Before choosing a model, measure:

- Space limits at the installation area

- Whether horizontal (platform) or vertical (wall/column) installation fits better

- Rope exit direction and whether a guide sheave is needed

Tell us your approximate space and installation orientation—we can immediately eliminate models that won’t fit.

6. Do you need compatibility with electric/pneumatic tools?

Though defined as a manual winch, many customers request:

- Ability to use a powered tool occasionally

- Light load but high-frequency operations

- Desire to reduce operator fatigue

If so, just tell us:

“I want the winch to be compatible with electric/pneumatic tools.”

We will consider interface shape, torque margin and safety protection to ensure:

manual operation as the main mode, tool assistance when needed.

III. From an Application Perspective: Where Does a Two-Speed Manual Winch Fit Best?

Scenario 1: Small-to-medium pulling tasks in warehouses/workshops

Very common use case.

Examples:

- Pulling pallet trucks, carts, tooling carriers near ramps or docks

- Moving machinery or spare parts in maintenance areas

- Occasional pulling tasks not worth installing an electric winch

Advantages:

- Human force is sufficient for loads from several hundred kg to 1–2 tons

- No electrical system needed—easy installation

- High-speed gear improves efficiency during idle travel

Scenario 2: Temporary lifting/pulling in construction sites without power

During construction:

- Power supply may be incomplete

- Conditions change quickly

- Tasks are temporary but necessary

Examples:

- Moving parts between floors

- Small lifting operations on temporary platforms or scaffolding

- Pulling/positioning equipment during installation

Installing a large electric winch too early can be costly and inconvenient.

A two-speed manual winch is plug-and-play, requiring no wiring and offering high safety and flexibility.

Scenario 3: As a built-in actuator inside equipment

Many integrators embed winches directly into their machines.

Examples:

- High-torque opening/closing of access doors or side panels

- Tensioning devices on test platforms

- Precise positioning mechanisms during assembly

In such cases, we adapt:

- Winch dimensions

- Mounting orientation

- Rope route and guide sheaves

- Protective design around the handle and housing

This is a natural strength of manual two-speed winches.

Scenario 4: Backup system that must remain reliable even if rarely used

Some customers use manual winches as standby units:

- Rarely used

- But must work perfectly when needed

Common in harsh environments:

- Seaside, docks, outdoor platforms

- Chemical areas where electrical devices are restricted

- Operations requiring the operator to be present and observe directly

For these projects, we emphasize long-term corrosion resistance and reliability—

so that even if unused for years, it still works when required.

IV. If You Want to Request a Quotation, Please Prepare This Information

To ensure accurate recommendations from the first communication, we suggest preparing:

- Application scenario: warehouse/workshop, construction, equipment integration, marine/chemical, etc.

- Main task: pulling / lifting / tensioning / positioning

- Maximum load (kg) and whether it rolls or slides

- Any slope and estimated steepness

- Travel distance and desired time per operation

- Operations per day/hour

- Space dimensions and desired mounting (vertical/horizontal)

- Whether power/air supply is available, need for tool compatibility

- Requirements for materials, corrosion resistance, explosion-proof, etc.

Send this information to us, and we will help:

- Calculate required pulling force and safety factor

- Recommend 1–2 suitable models

- Consider installation and rope routing

- Provide pricing and lead time suggestions

V. Final Note: Selection Is About Peace of Mind, Not Just Buying a Device

After years in the winch industry, one thing is clear:

Customers don’t care about “buying a 1-ton winch.”

They care about whether the winch is safe, practical and stable in their project.

A two-speed manual winch may look traditional, but it solves:

- Scenarios where electric winches are excessive

- Tasks where simple pulleys lack force

- Operations where “the operator must see and feel the load”

If you’re working on a project requiring small-to-medium pulling or lifting and unsure whether to use an electric winch, just share your working conditions with us.

We will tell you truthfully whether a two-speed manual winch is suitable—and provide a complete configuration if it is.

That way, every selection decision brings you closer to real peace of mind.